Two-gear type electric transmission free of gear shift power interruption

A technology of electric transmission and power interruption, which is applied to vehicle gearboxes, multi-gear ratio transmissions, transmission elements, etc., can solve the problems of difficulty in reducing volume and cost, reducing system complexity, and increasing the axial size of transmissions, and achieves improvement. The effect of vehicle drivability, reduced control difficulty, and improved drivability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

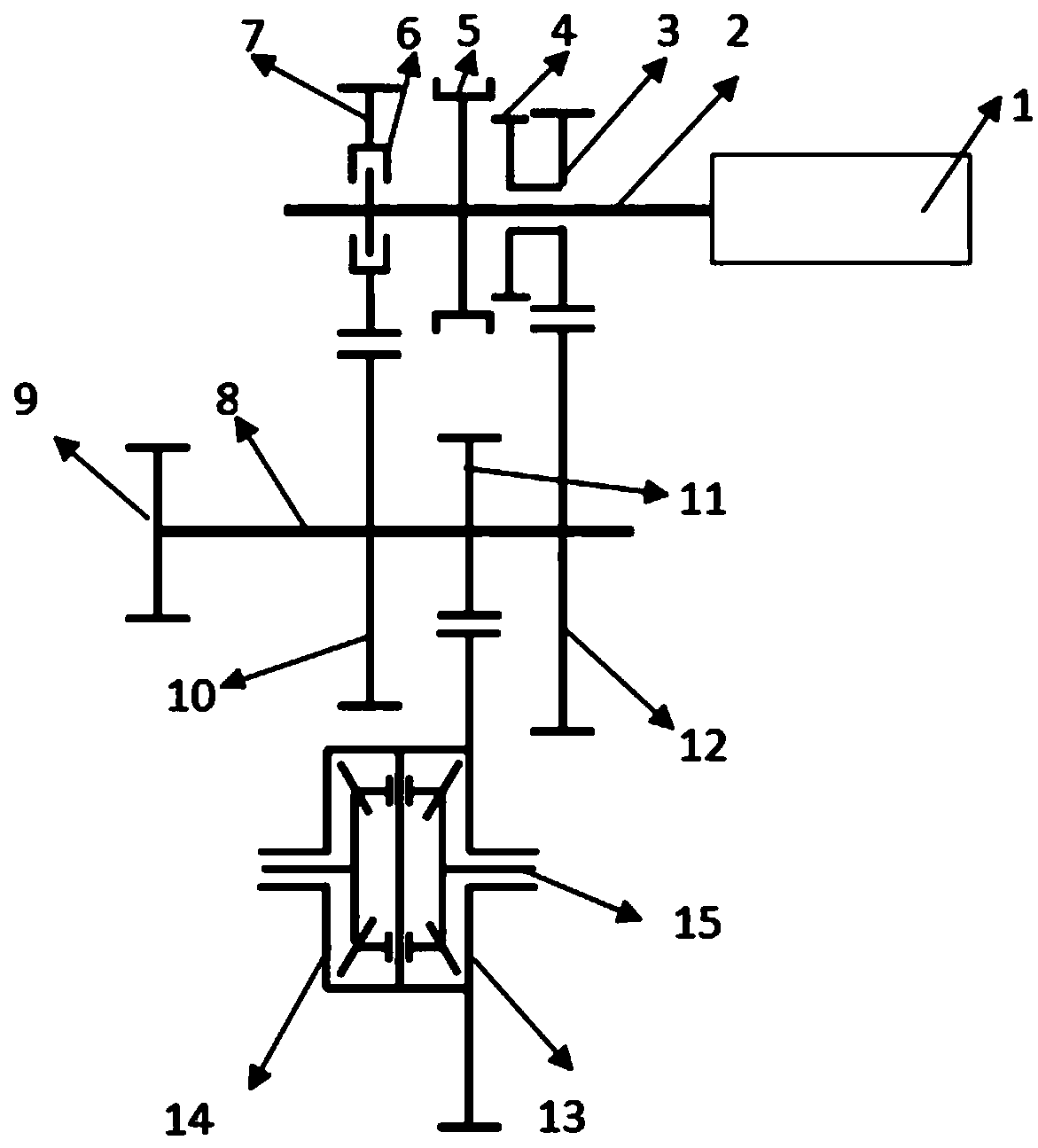

[0024] Such as figure 1 As shown, the present invention relates to a two-speed electric transmission without shifting power interruption, which is mainly composed of a drive motor 1, a transmission gear assembly, and a differential 14; the drive motor 1 is integrated inside the transmission; the The transmission gear assembly consists of input shaft 2, first gear driving gear 3, second gear driving gear 7, first gear driven gear 12, second gear driven gear 10, first shift element, second shift element 6, parking Ratchet 9, final drive gear 11, final drive driven gear 13, intermediate shaft 8, output shaft 15 form.

[0025] The first shifting element comprises a right engaging part 4 , a synchronizing part 5 and a left engaging part 16 . The input shaft 2 is directly connected with the drive motor 1 , and the first gear driving gear 3 and the second gear driving gear 7 are both hollowly sleeved on the input shaft 2 . The right engaging part 4 is fixedly connected to the first...

Embodiment 2

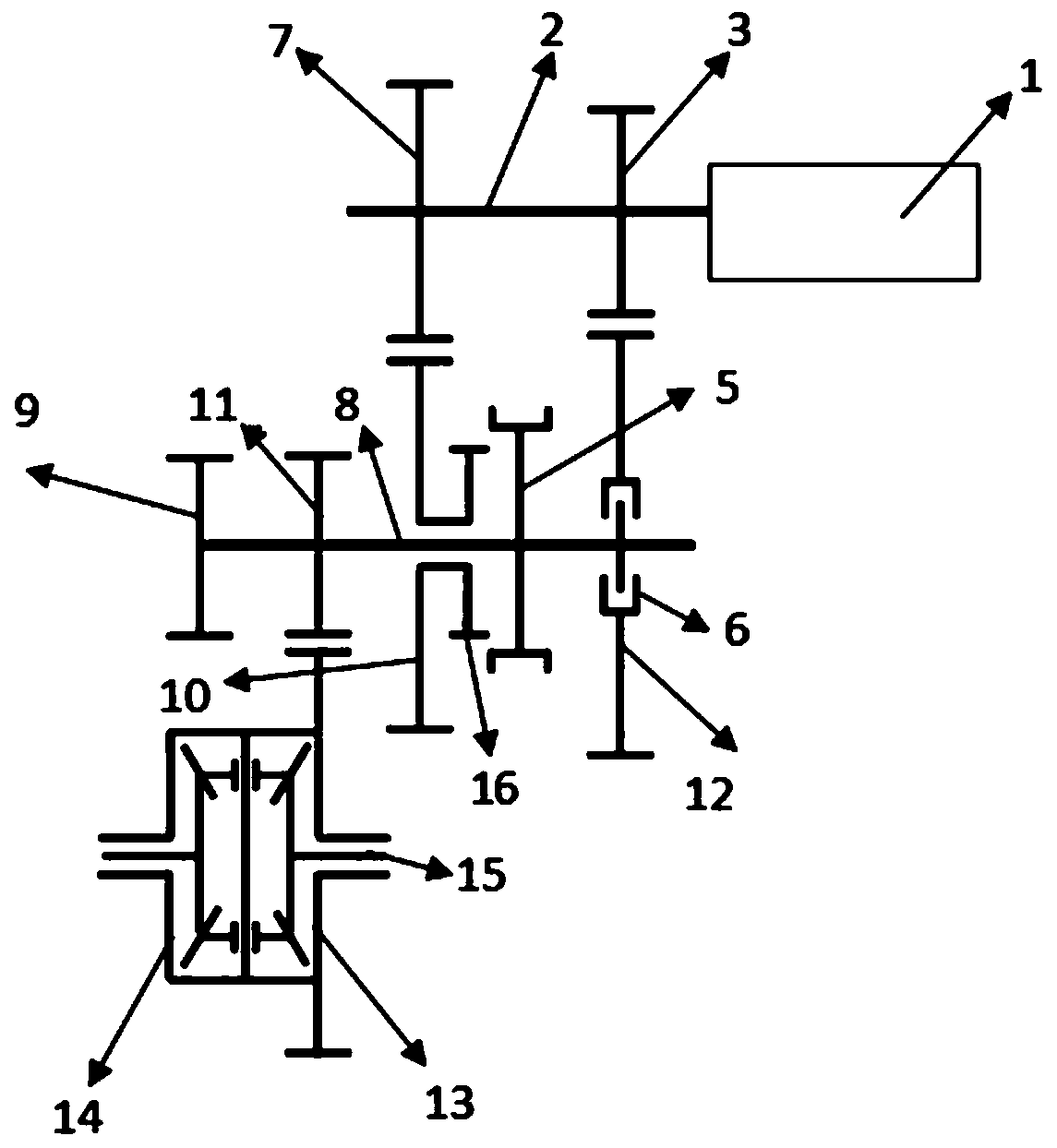

[0040] Such as figure 2 As shown, the present embodiment moves the original shifting element from the input shaft 2 to the intermediate shaft 8 on the basis of the first embodiment. Now the first gear driving gear 3 and the second gear driving gear 7 are all fixedly connected on the input shaft 2; The left engaging part 16 is connected with the second gear driven gear 10. When the left engaging part 16 and the synchronizing part 5 are engaged, the power of the driving motor 1 can be transmitted to the intermediate shaft 8 through the driven gear 10; the second The shifting element 6 is used to connect the first-speed driven gear 12 and the intermediate shaft 8 , and when it is in a closed state, the power of the driving motor 1 can be transmitted to the intermediate shaft 8 through the first-speed driven gear 12 .

[0041] Other structures in this embodiment are the same as those in Embodiment 1. The gear switching process of this embodiment is the same as that of Embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com