Preparation method of magnetic fluid for mineral separation, and device thereof

A magnetic fluid and grinding chamber technology, applied in the field of magnetic fluid preparation, can solve the problems of low energy utilization rate of ball mills, poor magnetic fluid effect, long time required, etc., and achieve high production speed, quality and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

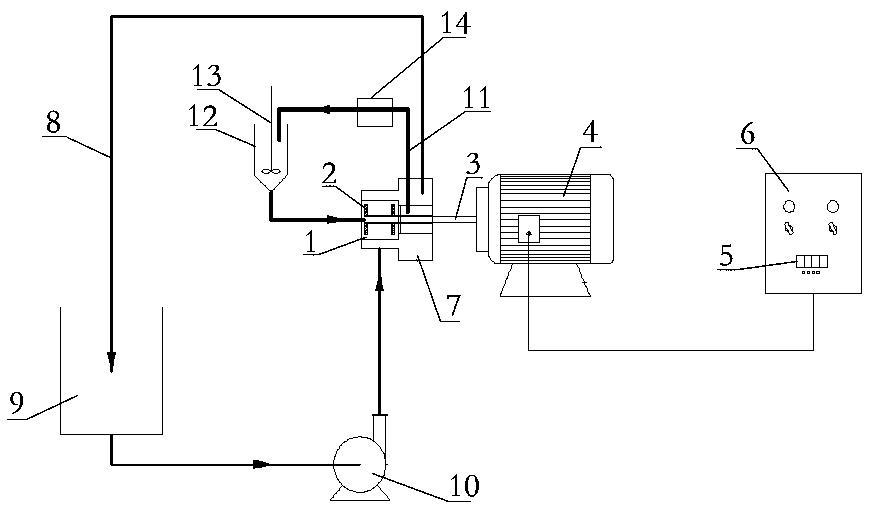

[0020] The technical solutions of the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0021] The invention provides a preparation method of magnetic fluid for mineral processing, comprising the following steps:

[0022] Step 1: Connect the stirring device of the grinding chamber with the frequency conversion motor, the grinding chamber is connected with the material circulation device, and a cooling water circulation device is installed outside the grinding chamber;

[0023] Step 2: Fill the grinding cavity with zirconia beads, and add cooling water to the cooling water circulation device;

[0024] Step 3: add 95-85 parts of distilled water and 5-15 parts of Fe by weight in the material circulation device 3 O 4 The powder is stirred evenly to obtain Fe 3 O 4 powder slurry, in which Fe 3 O 4 The fineness of the powder is 200 mesh;

[0025] Step 4: Open the material circulation device to make Fe 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com