Method for increasing the interface magnetic anisotropy energy of ferromagnetic metal/oxide bilayer film

A technology of magnetic anisotropy and ferromagnetic metals, which is applied in the field of high-density information storage and sensing, can solve the problems of interdiffusion of atoms in other layers, affecting the performance of PMA, and large dependence, and achieves simple preparation, convenient control, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

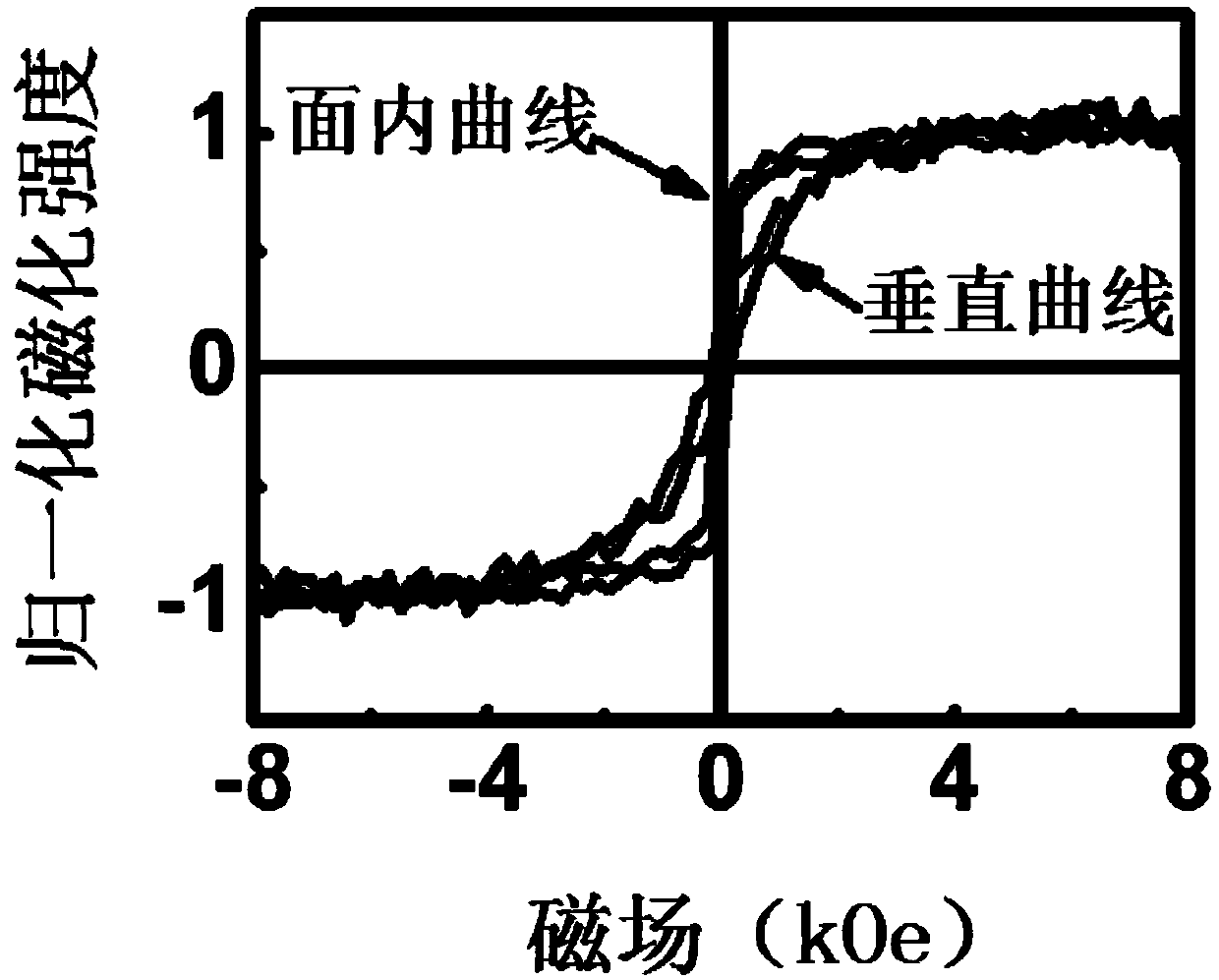

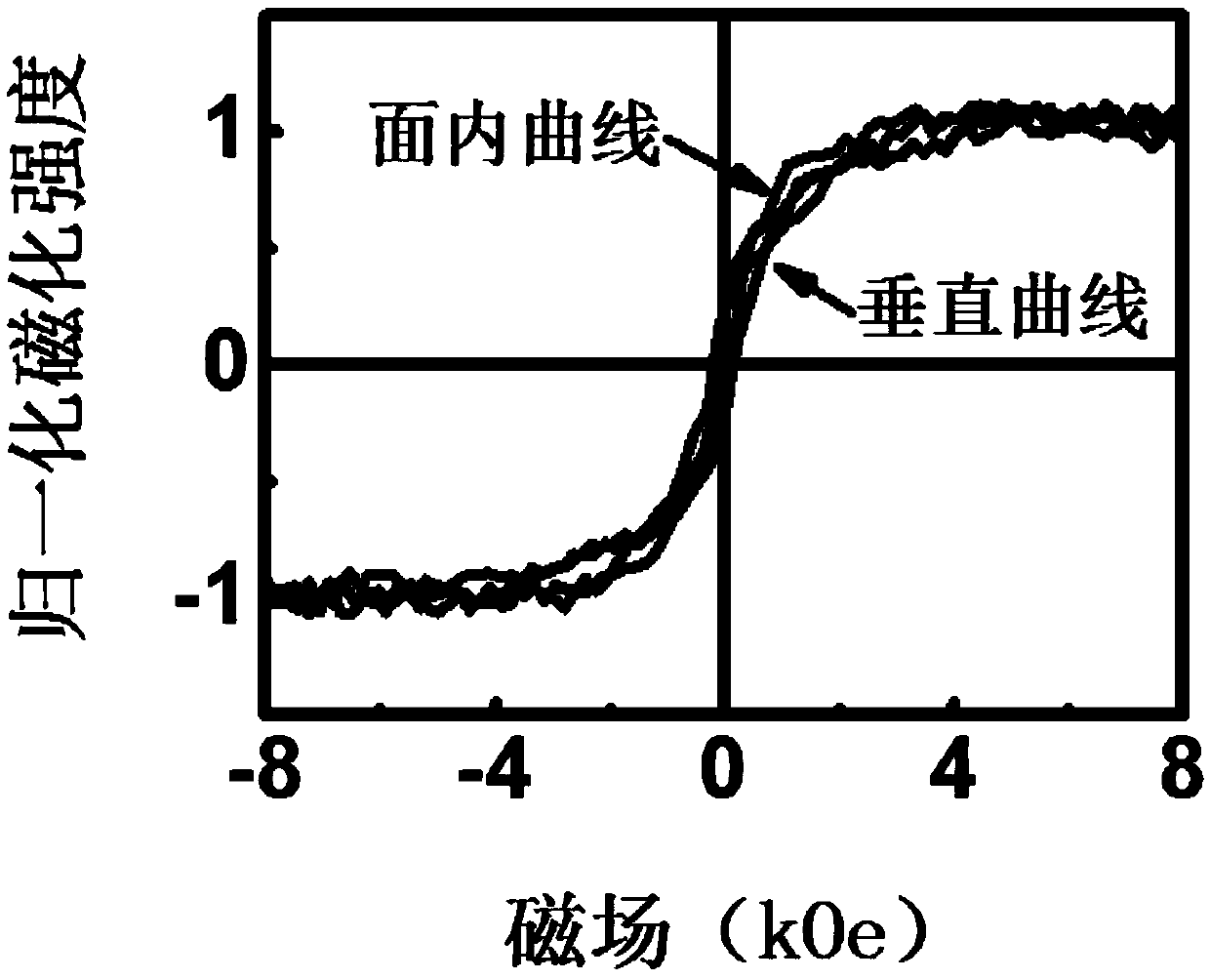

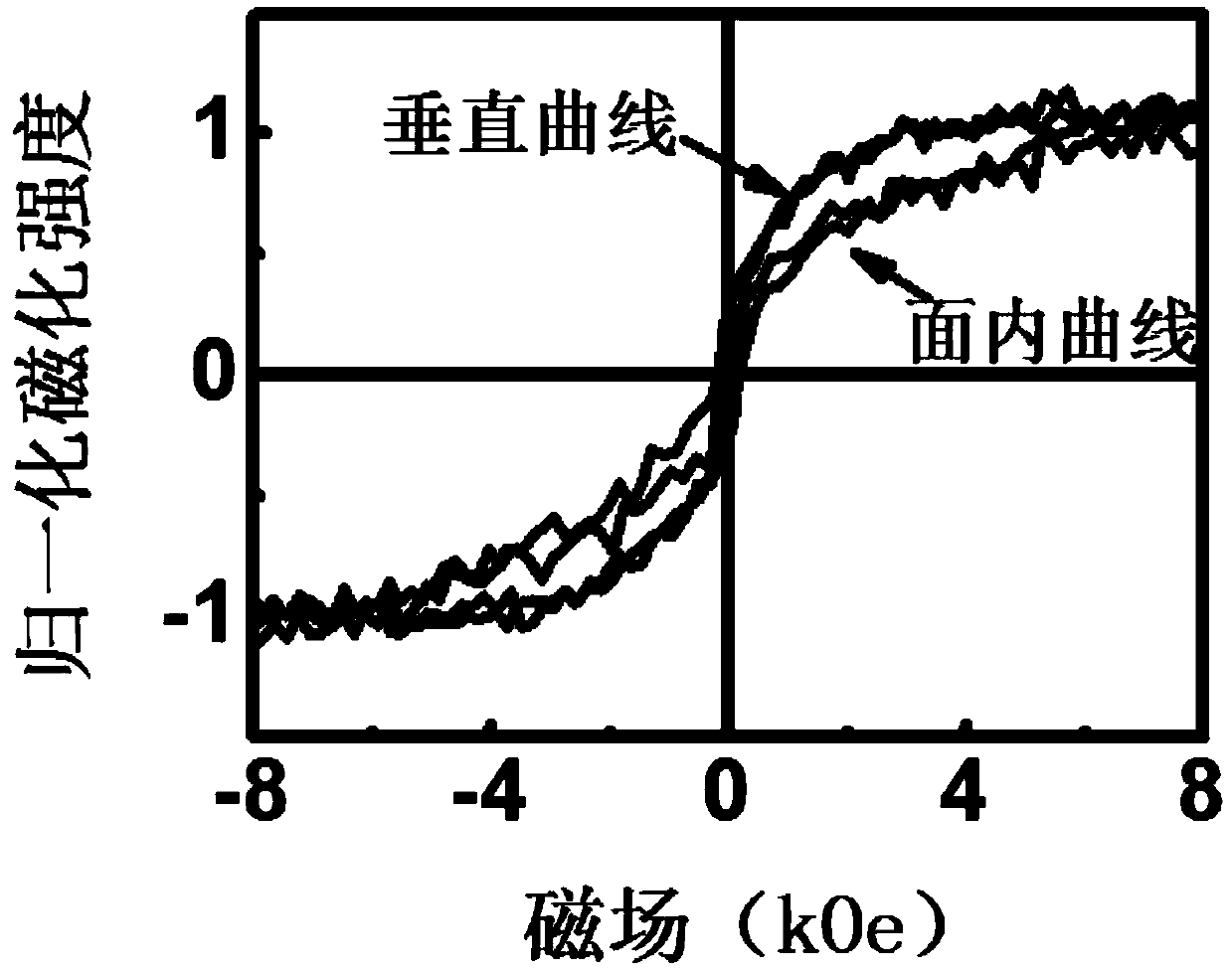

[0017] figure 1 The preparation conditions of the middle sample are as follows: firstly, the surface acidification treatment is carried out on the Si substrate, wherein the thickness of the substrate is 0.5 mm; the pH value of the surface acidification treatment is 6, and the acidification time is 3 minutes. Then, utilize magnetron sputtering method, on the Si substrate after above-mentioned treatment, deposit Cr atom (thickness is ), FeN x atoms (thickness is ), MgO atoms (thickness is ) and Ta atoms (thickness is ), thus preparing the Si substrate Multi-layer film, the background vacuum before sputtering deposition is 2×10 -5 Pa, the argon pressure during sputtering is 0.3Pa. When preparing the FeN layer, the argon / nitrogen pressure ratio is 6:1, and the N atom content x is 0.1. After the deposition is completed, it is heat-treated in a vacuum environment with a vacuum degree of 1×10 -5 Pa, 100 °C / 20 min to promote uniform occupation of N atoms at interstitia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com