Selective catalytic reduction (SCR) denitrification ammonia-spraying optimization method and system based on advanced measuring instrument and advanced control algorithm

A measuring instrument and advanced control technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems that the measured data cannot represent the average concentration, the overshoot of the control system is large, and the excessive discharge, etc., to solve the problem of ammonia. The effect of inaccurate escape strategy, high system response rate, and stable emission standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

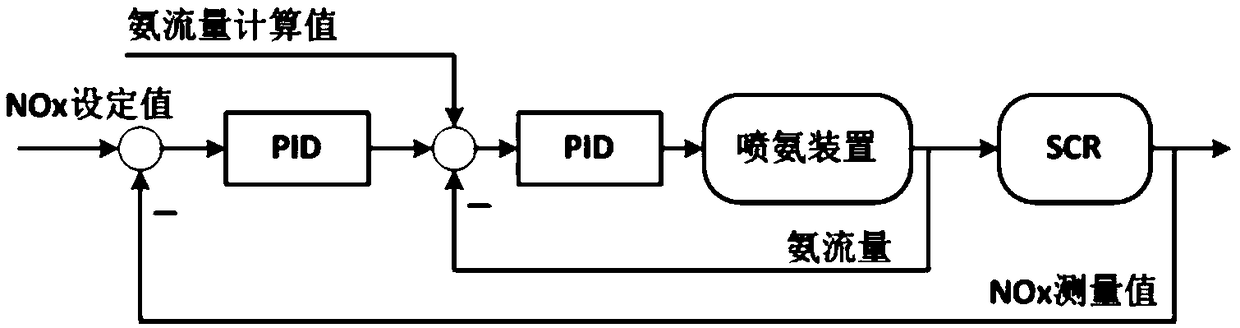

[0046] This program mainly proposes a denitrification optimization control method flow combining soft measurement of inlet nitrogen oxide concentration and working condition self-adaptive PID.

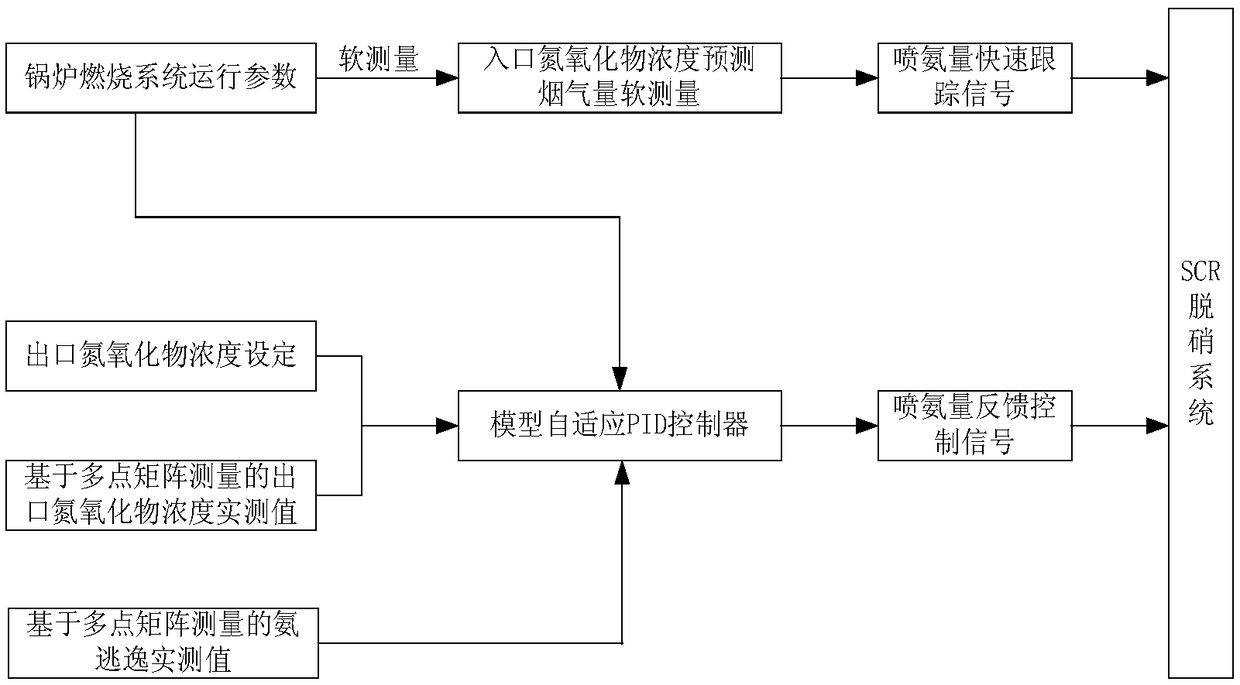

[0047]The invention firstly collects the primary air, secondary air, load and other data of the combustion system of the coal-fired thermal power unit and the inlet nitrogen oxide concentration corresponding to these parameters, and establishes the inlet nitrogen oxide concentration model.

[0048] Such as figure 2 As shown, based on parameters such as boiler primary air volume, secondary air volume, coal supply volume, and the number of operating units of the pulverizing system, according to the above inlet nitrogen oxide concentration model, the predicted value of the inlet nitrogen oxide concentration is obtained, and then multiplied by the flue gas volume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com