Wood grinding device

A technology of wood and grinding rollers, which is applied in the directions of grinding/polishing safety devices, grinding machines, transportation and packaging, etc., which can solve the problems of ineffective use and low efficiency of the return of the push mechanism, and achieve improved efficiency, high efficiency, and device The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

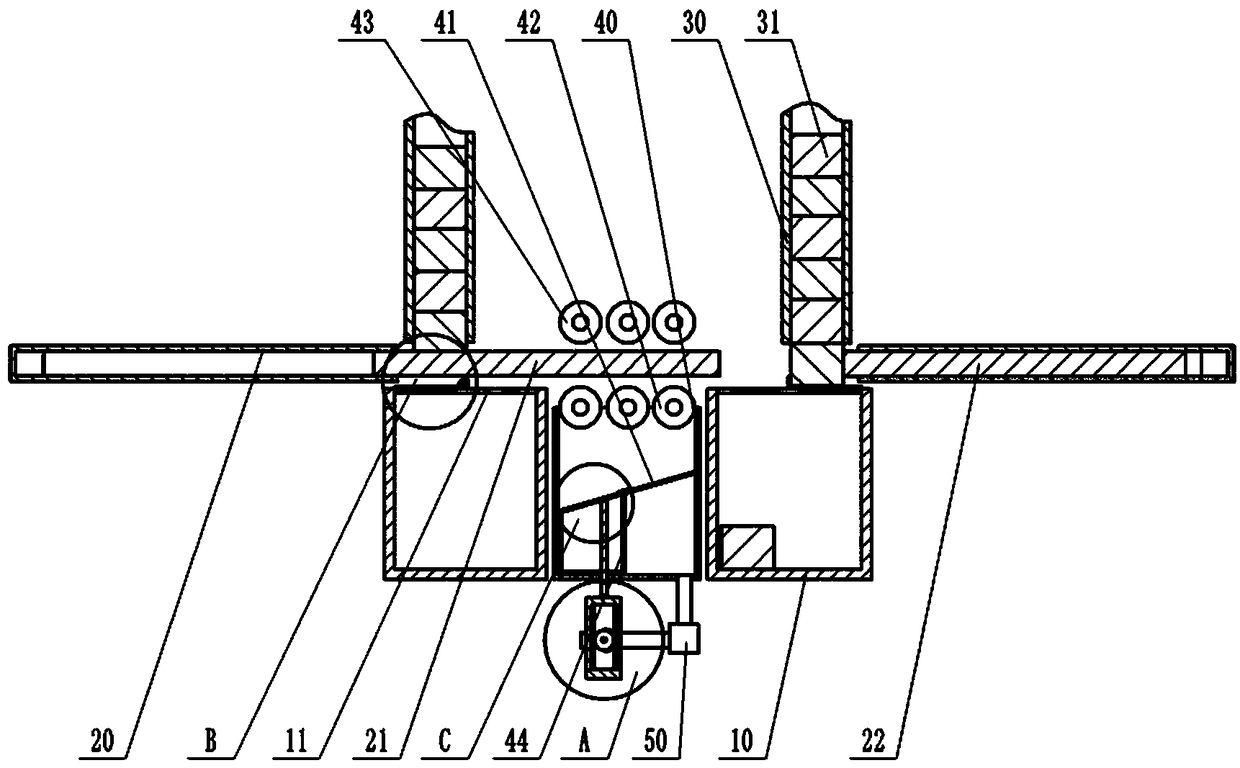

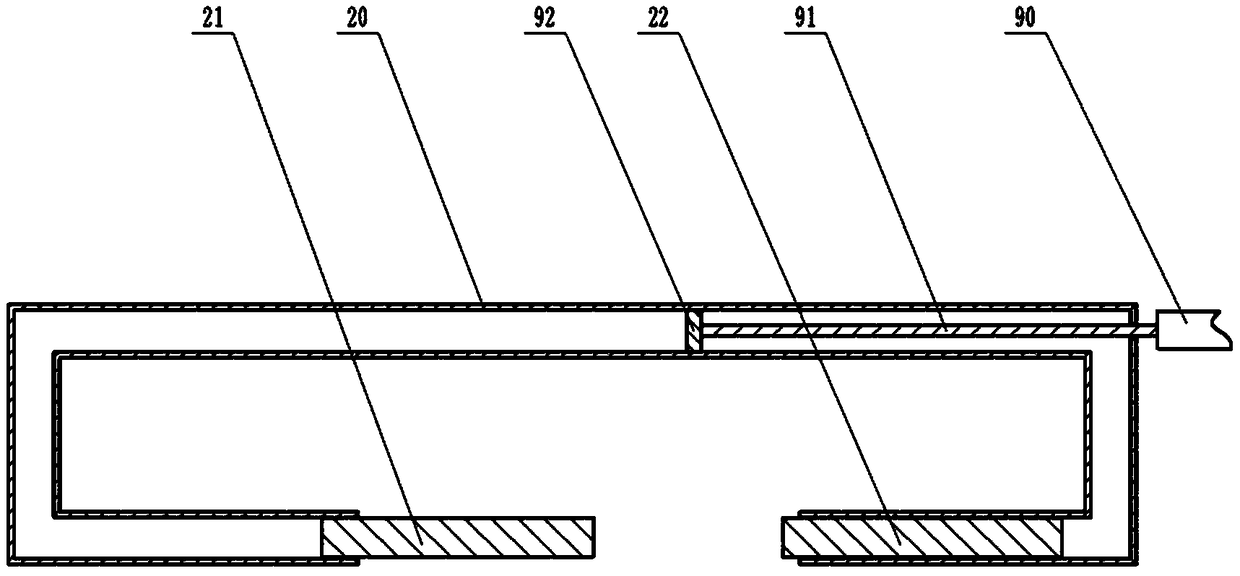

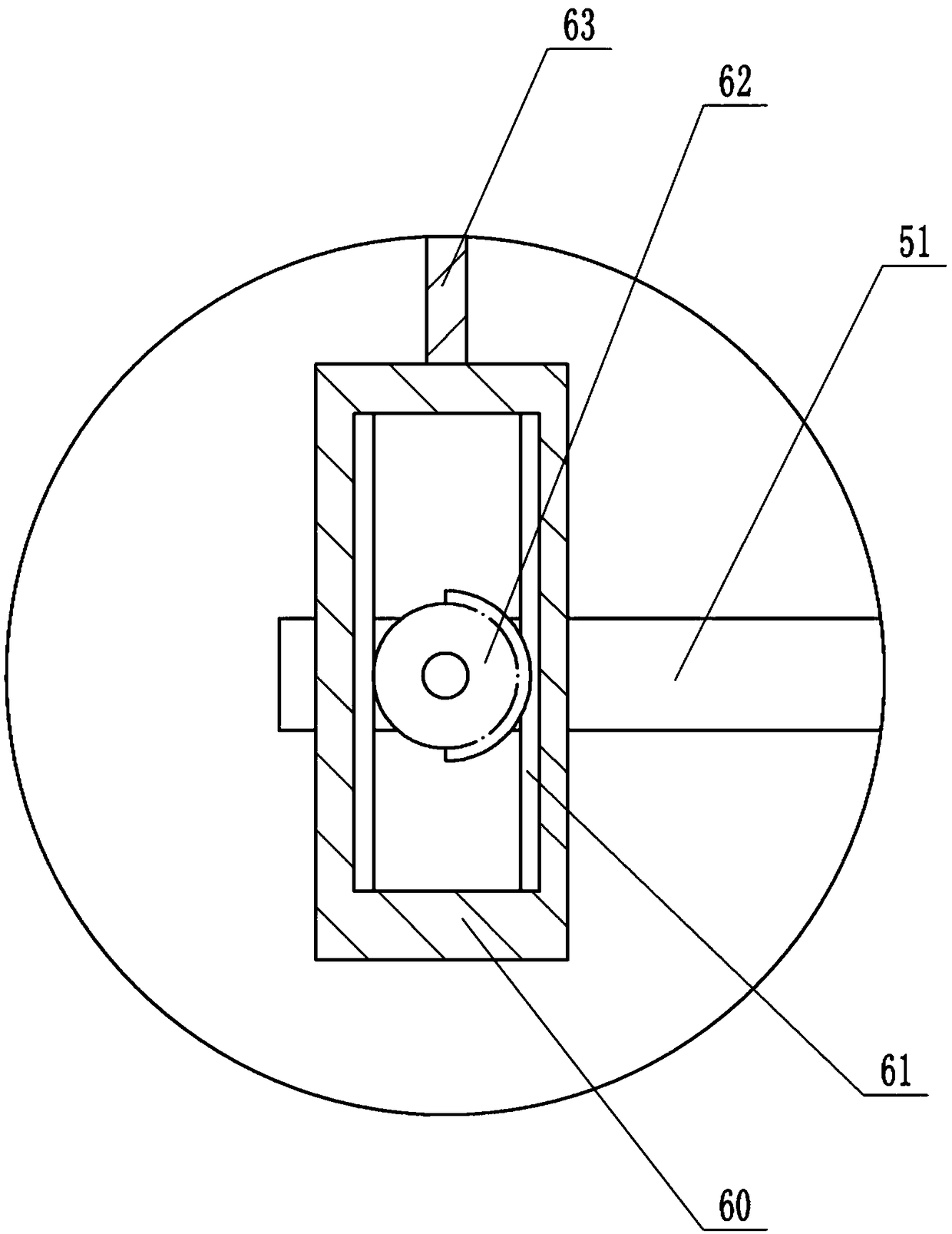

[0021] Instructions attached Figures 1 to 5 The reference signs in include: placement box 10, blanking opening 11, strip groove 12, connecting pipe 20, second plunger 21, first plunger 22, storage pipe 30, wood 31, dust collection box 40, filter Net 41, lower grinding roller 42, upper grinding roller 43, dust collection box 44, negative pressure pump 50, exhaust pipe 51, sliding frame 60, rack 61, incomplete gear 62, sliding rod 63, sliding plate 70, push plate 72. The second spring 71, the slide block 73, the first spring 74, the turnover plate 80, the protrusion 81, the hydraulic cylinder 90, the piston rod 91, and the piston 92.

[0022] Such as figure 1 , figure 2 As shown, the wood grinding device includes a vacuum unit, a power unit, a grinding unit, and placement units located on the left and right sides of the grinding unit. The placement unit includes a placement box 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com