Hoisting device for prefabricated segments and hoisting method thereof

A hoisting device and segment technology, which is used in transportation and packaging, load hoisting elements, walking mechanisms, etc., can solve the problems of strict hoisting weight requirements, large restrictions on hoisting of pipe galleries, and prolonged construction period, etc. The effect of convenient erection, simplified hoisting process and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

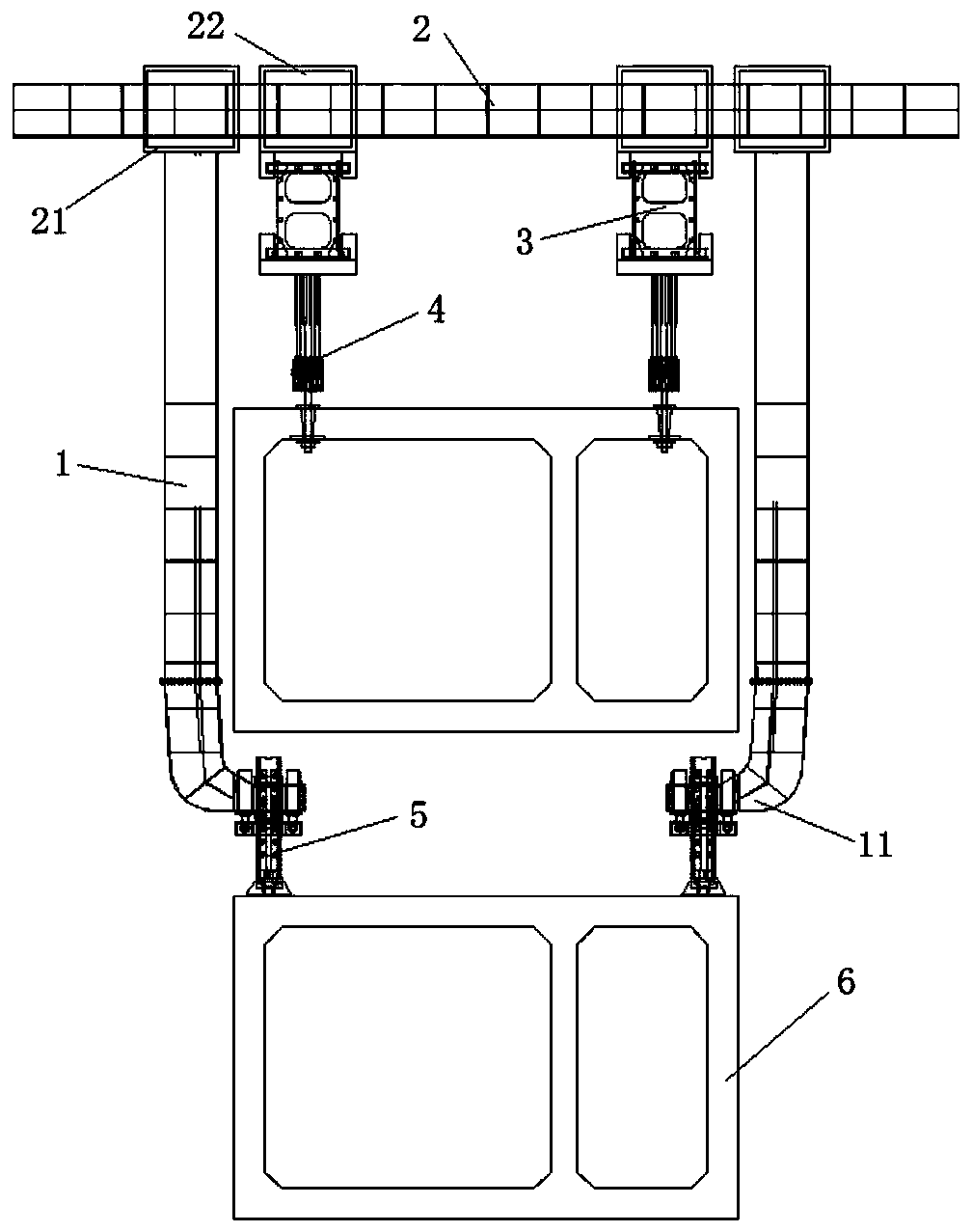

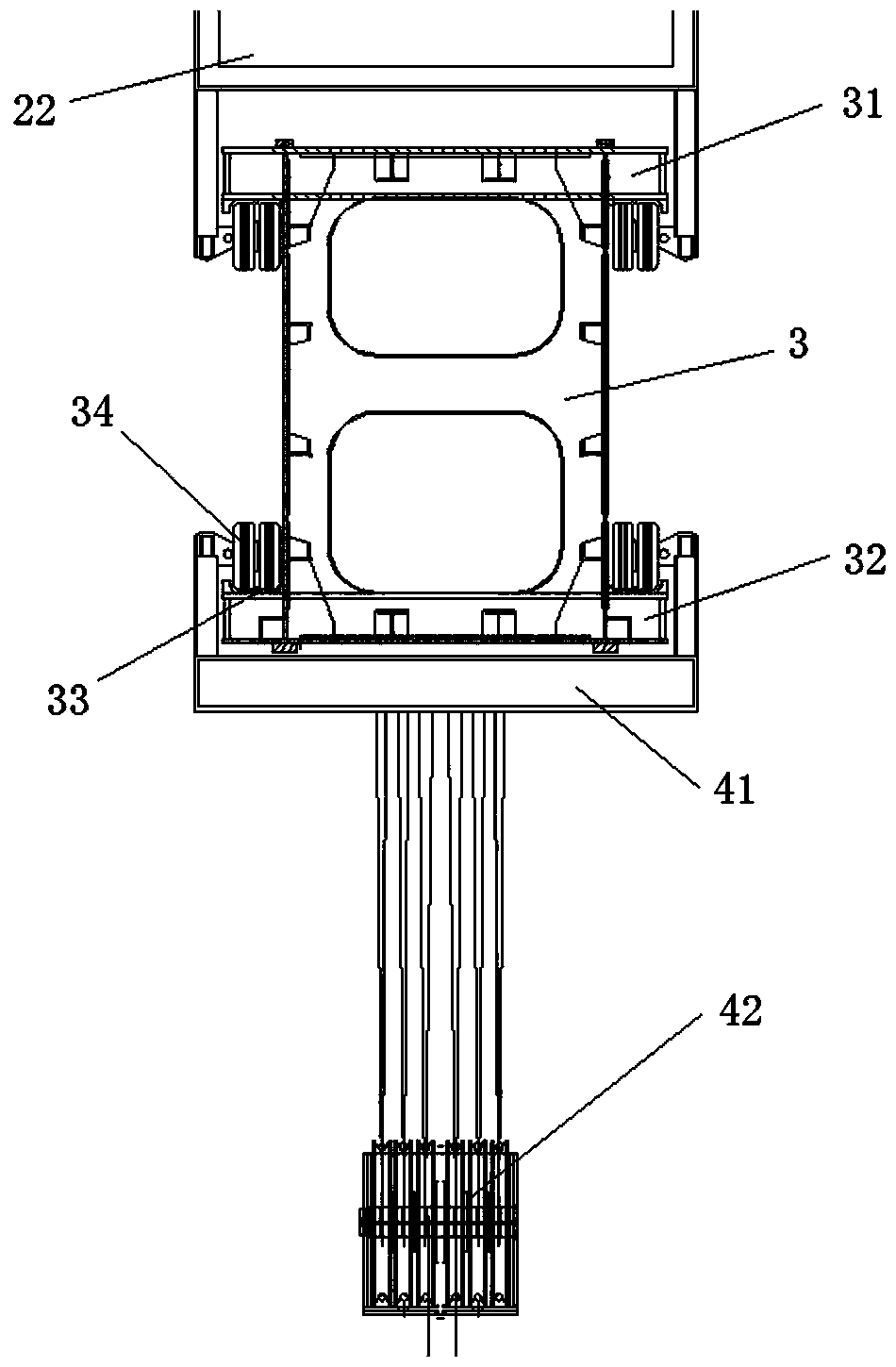

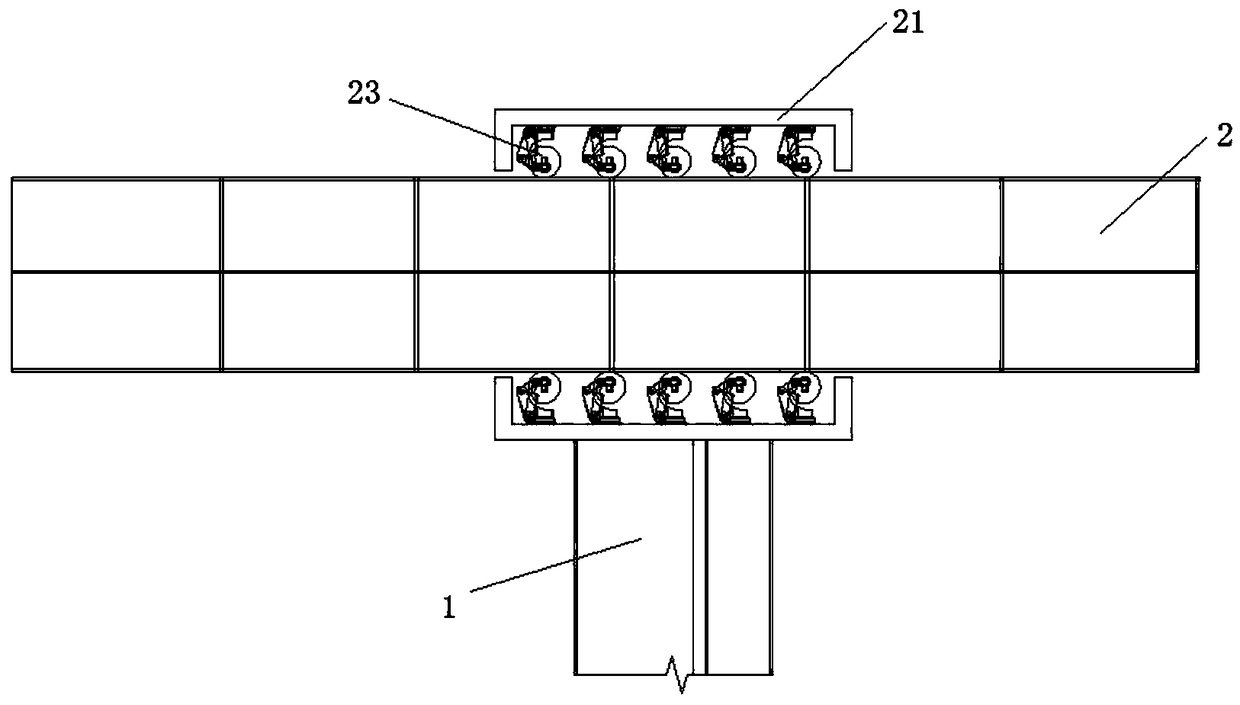

[0051] Such as Figure 1-5 As shown, a hoisting device for prefabricated segments is provided in this embodiment, which mainly includes a support column 1, a beam 2 arranged on the support column 1, a longitudinal beam 3 arranged on the beam 2, and a longitudinal beam arranged on the longitudinal beam 2. The hoisting mechanism 4 on the beam 3.

[0052] One end of the supporting column 1 is provided with a bent portion 11 , and the supporting device 5 is disposed on the bent portion 11 . The other end of the support column 1 is slidably connected to the beam 2 . As a preferred solution, the support device 5 includes a support part 51, a height-adjustable column 52 arranged on the support part 51, and a height-adjustable column 52 provided on the column 52 for adjusting the height of the bending part 11. Adjusting device; the support part 51 is provided with a rotating wheel 511 . Further, the upright 52 includes a first upright and a second upright that are nested in each ot...

Embodiment 2

[0060] The same as in Embodiment 1 will not be repeated, such as Image 6 As shown, in this embodiment, the bending parts 11 are arranged on the ground on both sides of the prefabricated segment 6 in opposite directions. Moreover, an arc-shaped contact structure is provided between the support portion 51 and the column 52, the arc-shaped contact includes an arc-shaped concave surface 522 provided on the support portion 51, and an arc-shaped concave surface 522 is provided on the column 52 corresponding to the arc-shaped concave surface 522. The arc-shaped protrusion 521 at the end is fixedly installed between the support column 1 and the fixed surface through the contact between the arc-shaped protrusion 521 and the arc-shaped concave surface 522, and can be applied to uneven ground.

Embodiment 3

[0062] In order to facilitate the understanding of the scheme, based on the hoisting device described in Example 1, such as Figure 7-9 As shown, a hoisting method is provided in this embodiment:

[0063] Firstly, segmental design is carried out on the embedded parts, and the members with regular cross-section are divided according to a certain length, and the division principle meets the transportation conditions. That is to say, within the effective length, the segment can withstand the load generated by the segment and the racking equipment. The second is to prefabricate the sections, using factory prefabrication to process the underground section box structure, and the required components are produced and processed by the prefabrication factory to ensure quality and reduce environmental pollution during production. Then the foundation pit 7 is excavated. The foundation pit 7 can be excavated in the form of grading excavation or steel sheet piles, and the segment length ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com