Magnesium-zinc-selenium alloy material for kitchen ware and preparation method thereof

The technology of an alloy material and a manufacturing method is applied in the field of magnesium-zinc-selenium alloy materials for kitchen utensils and its preparation, which can solve the problems of hidden dangers to human health, poor thermal conductivity, and heavy weight, and achieve benefits to human health, simple preparation methods, and good thermal conductivity. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

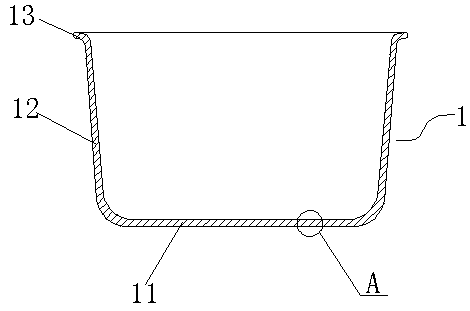

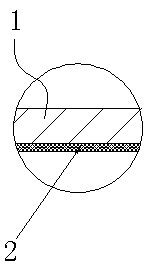

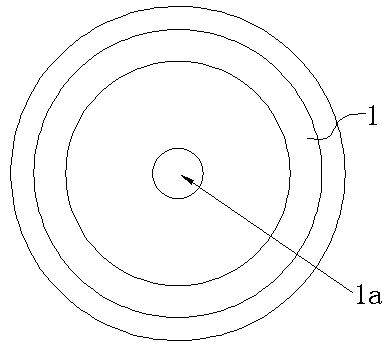

[0026] Such as Figure 1 to Figure 3 Shown is the structural representation of the present invention,

[0027] The reference signs therein are: liner body 1 , exposed area 1 a , bottom 11 , side wall 12 , flange 13 , and titanium porcelain coating 2 .

[0028] A magnesium-zinc-selenium alloy material for kitchen utensils, the weight ratio of each component of the magnesium-zinc-selenium alloy material is: 1% to 5% of zinc, 0.3% to 1% of calcium, 0.2% to 0.5% of selenium, and the rest is magnesium.

[0029] A kind of preparation method of magnesium-zinc-selenide alloy material for kitchen utensils, comprises the following steps:

[0030] Step 1. Put the preheated pure magnesium ingot and the magnesium-calcium master alloy with a calcium content of 20% to 30% into the crucible for heating and melting, and cover and protect it with flux;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com