Overflow protection device for polysilicon water-cooled ingot furnace

An overflow protection and water cooling device technology, applied in the direction of polycrystalline material growth, single crystal growth, single crystal growth, etc., can solve the problems of furnace shell bursting, incomplete isolation, furnace pressure surge, etc., to prevent water flow gasification, Simple structure and the effect of reducing the probability of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

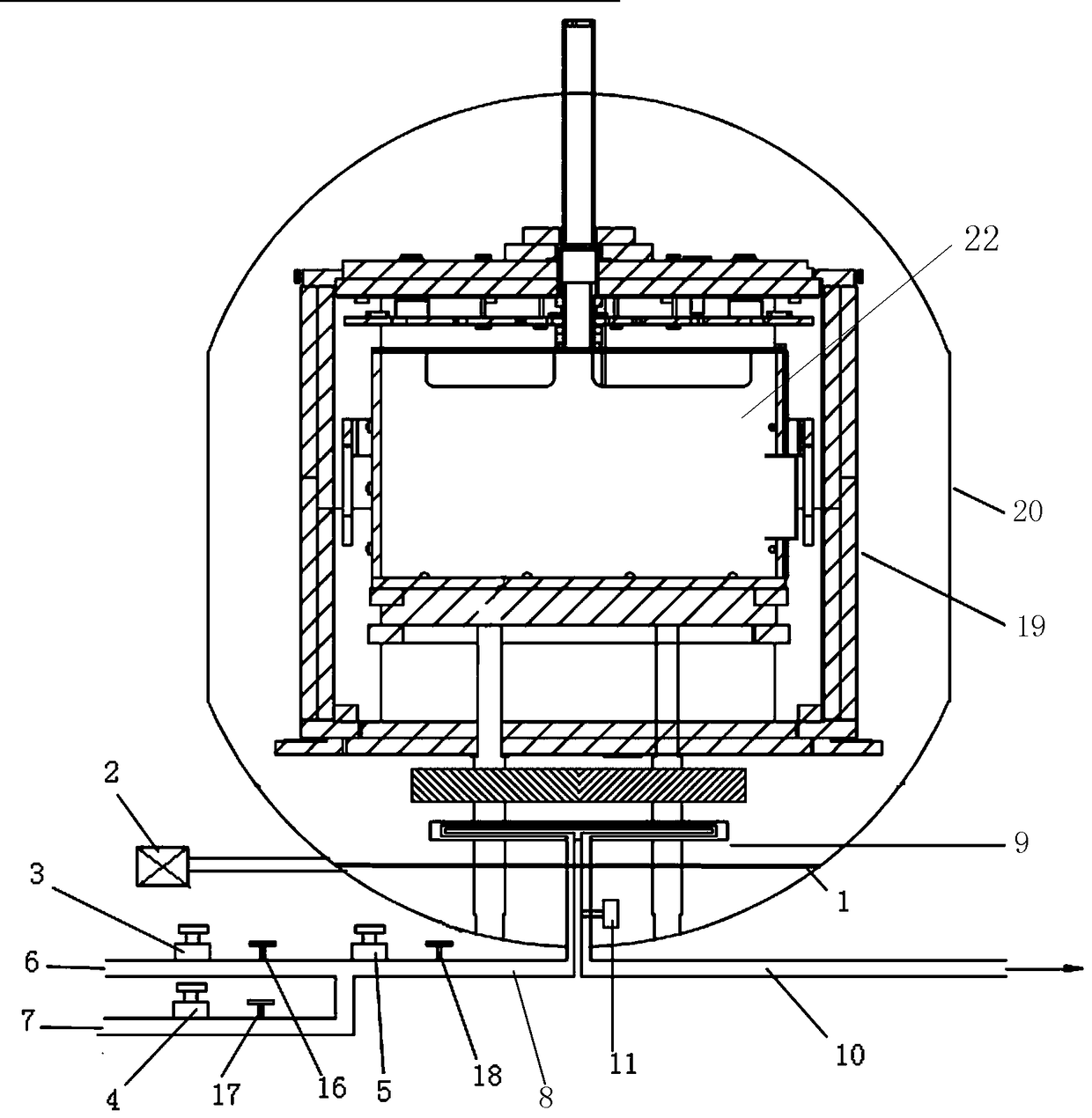

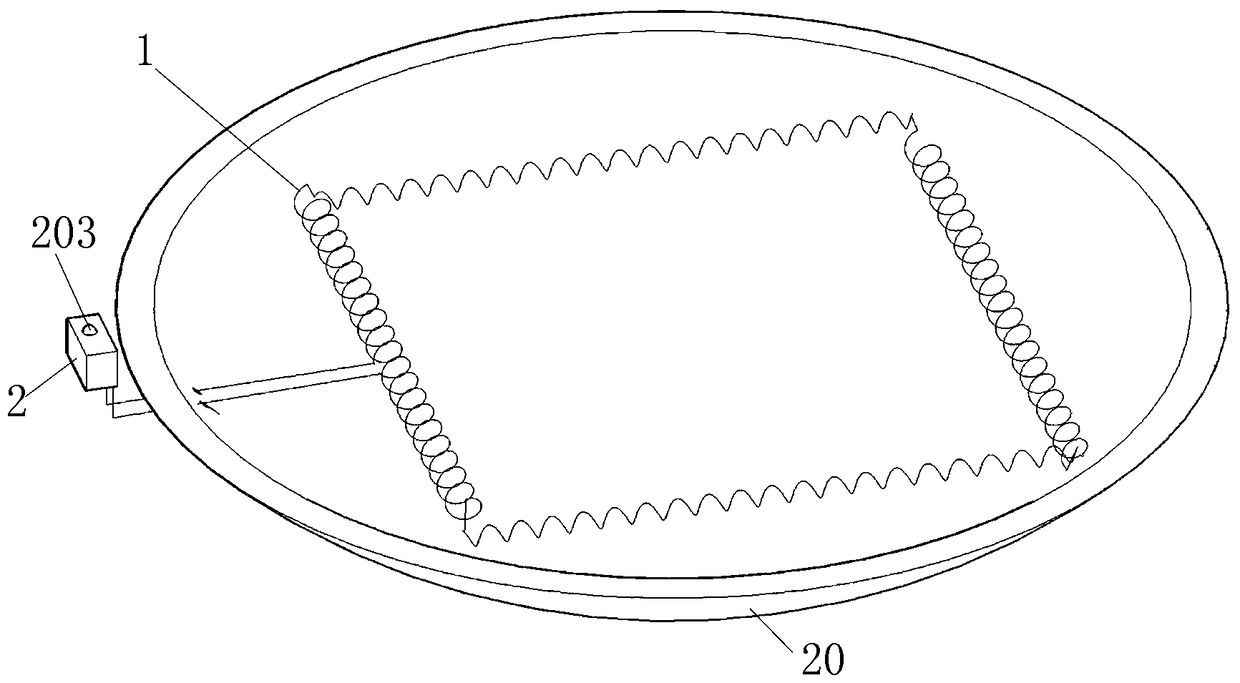

[0028] The preferred solution is as figure 1 As shown, a polysilicon water-cooled ingot furnace overflow protection device includes a thermal resistance wire 1 and a water cooling device arranged in the furnace shell 20, and the thermal resistance wire 1 is located below the water cooling device;

[0029] The thermal resistance wire 1 is electrically connected to the control device 2, and a resistance transmitter 201 is provided in the control device 2, and the resistance transmitter 201 is electrically connected to the thermal resistance wire 1 to detect the on-off state of the thermal resistance wire 1;

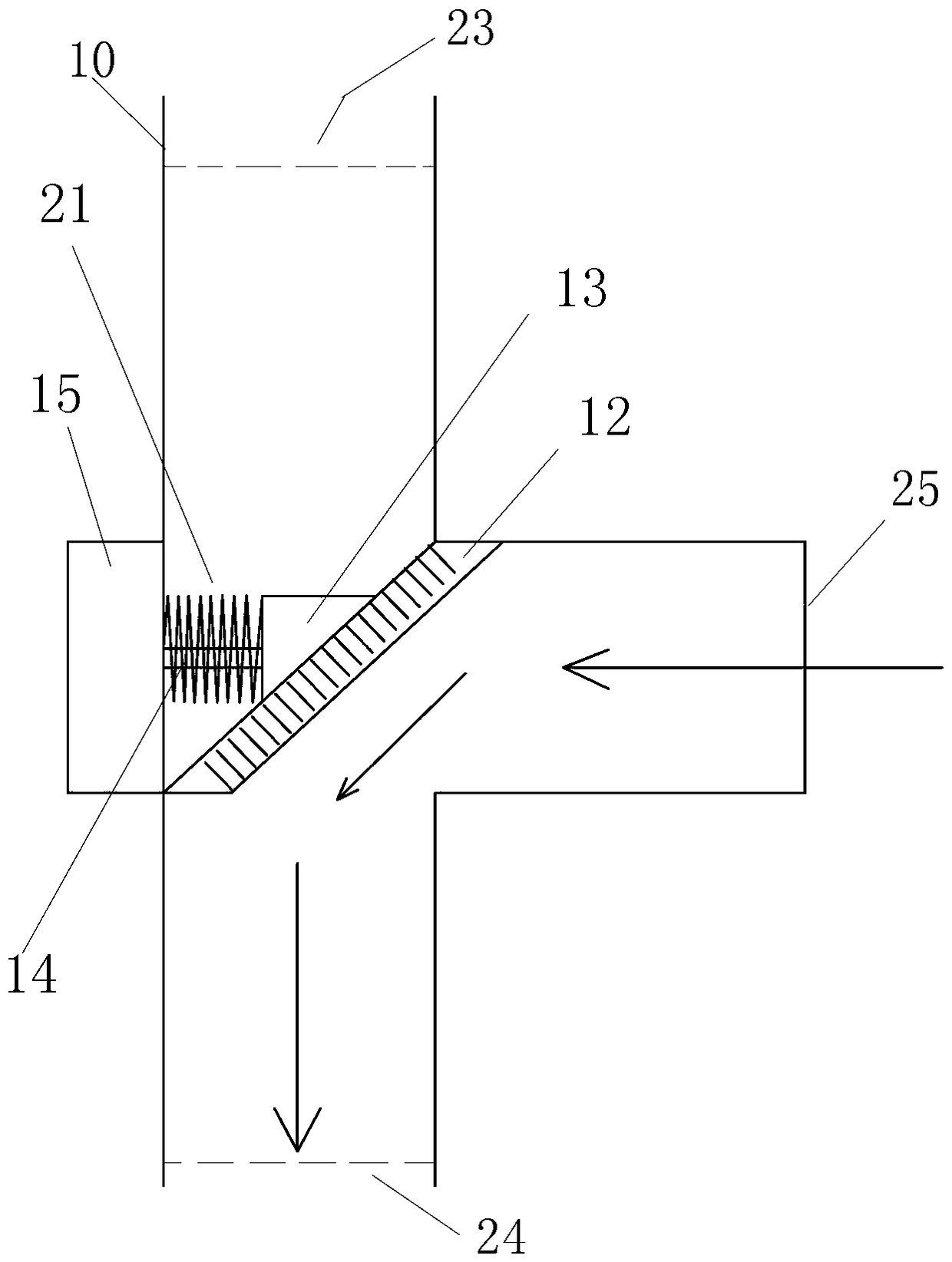

[0030] The input end of the water cooling device is connected to one end of the first main pipe 8, and the other end of the first main pipe 8 is connected to the water pipe 6 and the air pipe 7. The water pipe 6 is provided with a first valve 3, and the air pipe 7 is provided with a second valve. 4. The control device 2 is electrically connected to the first valve 3 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com