Two-dimensional material photoelectric detector with embedded reflecting mirror and fabrication method and application thereof

A photodetector and two-dimensional material technology, applied in the field of micro-nano optoelectronics, can solve the problems of low light absorption efficiency, small area, restricting the performance of photodetectors, etc., and achieve the effect of improving light absorption efficiency, high efficiency, and improving photoelectric detection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

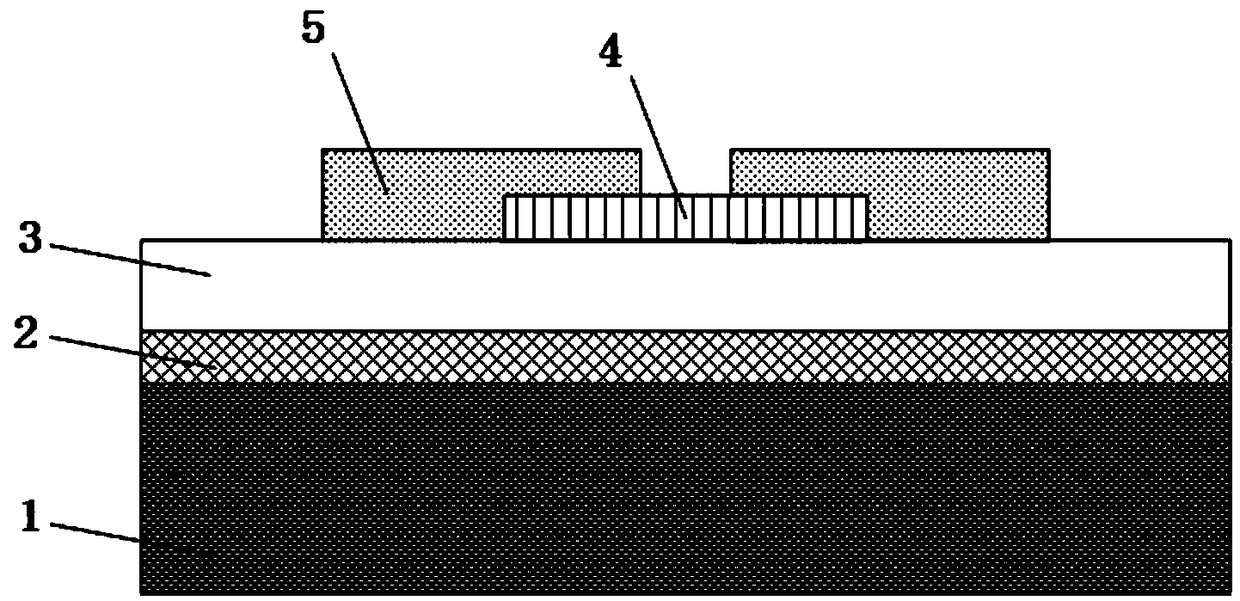

[0022] A two-dimensional material photodetector with embedded mirrors, such as figure 1 As shown, a substrate 1 , a metal mirror 2 , a dielectric layer 3 , a two-dimensional material 4 , and a source-drain electrode 5 are sequentially included from bottom to top.

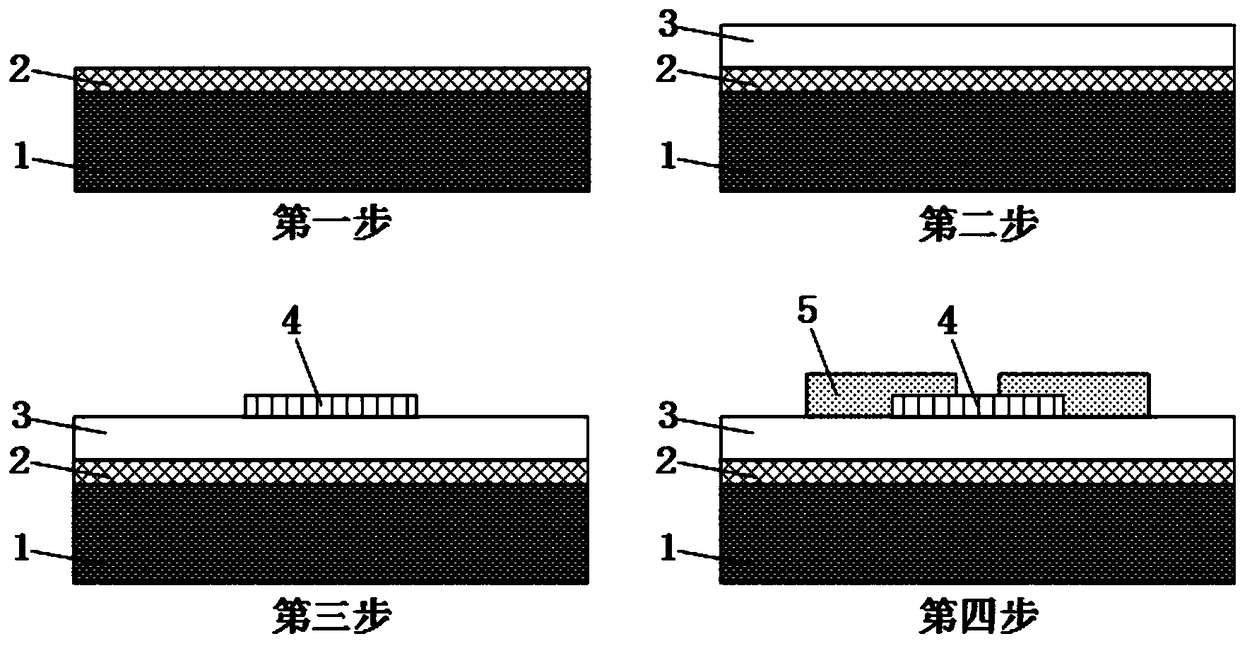

[0023] like figure 2 As shown, the preparation method of the above-mentioned two-dimensional material photodetector with built-in reflector comprises the following steps:

[0024] In the first step, a metal mirror 2 with high reflectivity is plated on the substrate 1; wherein, the material used for the substrate 1 is silicon, and the material used for the metal mirror 2 is silver.

[0025] In the second step, a dielectric layer 3 is plated on the metal reflector 2; wherein, the material used for the dielectric layer 3 is zirconium dioxide.

[0026] In the third step, the two-dimensional material 4 is grown on the dielectric layer 3 by chemical vapor deposition; wherein, the material used for the two-dimensional m...

Embodiment 2

[0029] A two-dimensional material photodetector with embedded mirrors, such as figure 1 As shown, a substrate 1 , a metal mirror 2 , a dielectric layer 3 , a two-dimensional material 4 , and a source-drain electrode 5 are sequentially included from bottom to top.

[0030] like figure 2 As shown, the preparation method of the above-mentioned two-dimensional material photodetector with built-in reflector comprises the following steps:

[0031] In the first step, a metal mirror 2 with high reflectivity is coated on the substrate 1; wherein, the material used for the substrate 1 is germanium, and the material used for the metal mirror 2 is aluminum.

[0032] In the second step, a dielectric layer 3 is plated on the metal reflector 2; wherein, the material used for the dielectric layer 3 is hafnium dioxide.

[0033] The third step is to grow the two-dimensional material 4 on the dielectric layer 3 by chemical vapor deposition; wherein, the material used for the two-dimensional m...

Embodiment 3

[0036] A two-dimensional material photodetector with embedded mirrors, such as figure 1 As shown, a substrate 1 , a metal mirror 2 , a dielectric layer 3 , a two-dimensional material 4 , and a source-drain electrode 5 are sequentially included from bottom to top.

[0037] like figure 2 As shown, the preparation method of the above-mentioned two-dimensional material photodetector with built-in reflector comprises the following steps:

[0038] In the first step, a metal mirror 2 with high reflectivity is coated on the substrate 1; wherein, the material used for the substrate 1 is germanium, and the material used for the metal mirror 2 is aluminum.

[0039] In the second step, a dielectric layer 3 is plated on the metal reflector 2; wherein, the material used for the dielectric layer 3 is hafnium dioxide.

[0040] In the third step, the two-dimensional material 4 is grown on the dielectric layer 3 by using a micromechanical lift-off method; wherein, the material used for the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com