Preparation method of fish sauce

A fish meal and protease technology, applied in food ingredients as taste improver, food science and other directions, can solve problems such as heavy bitterness and poor flavor, achieve no rancid smell, elegant sauce flavor, and improve the effect of finished product flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

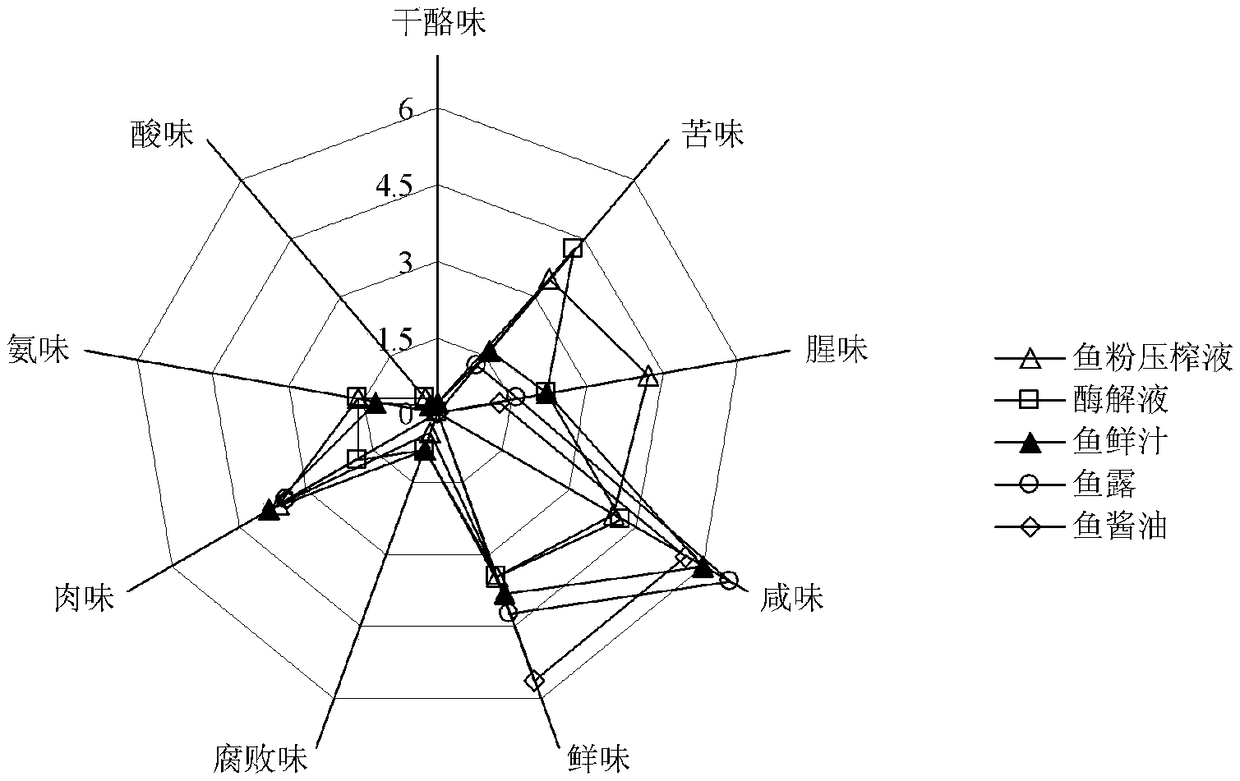

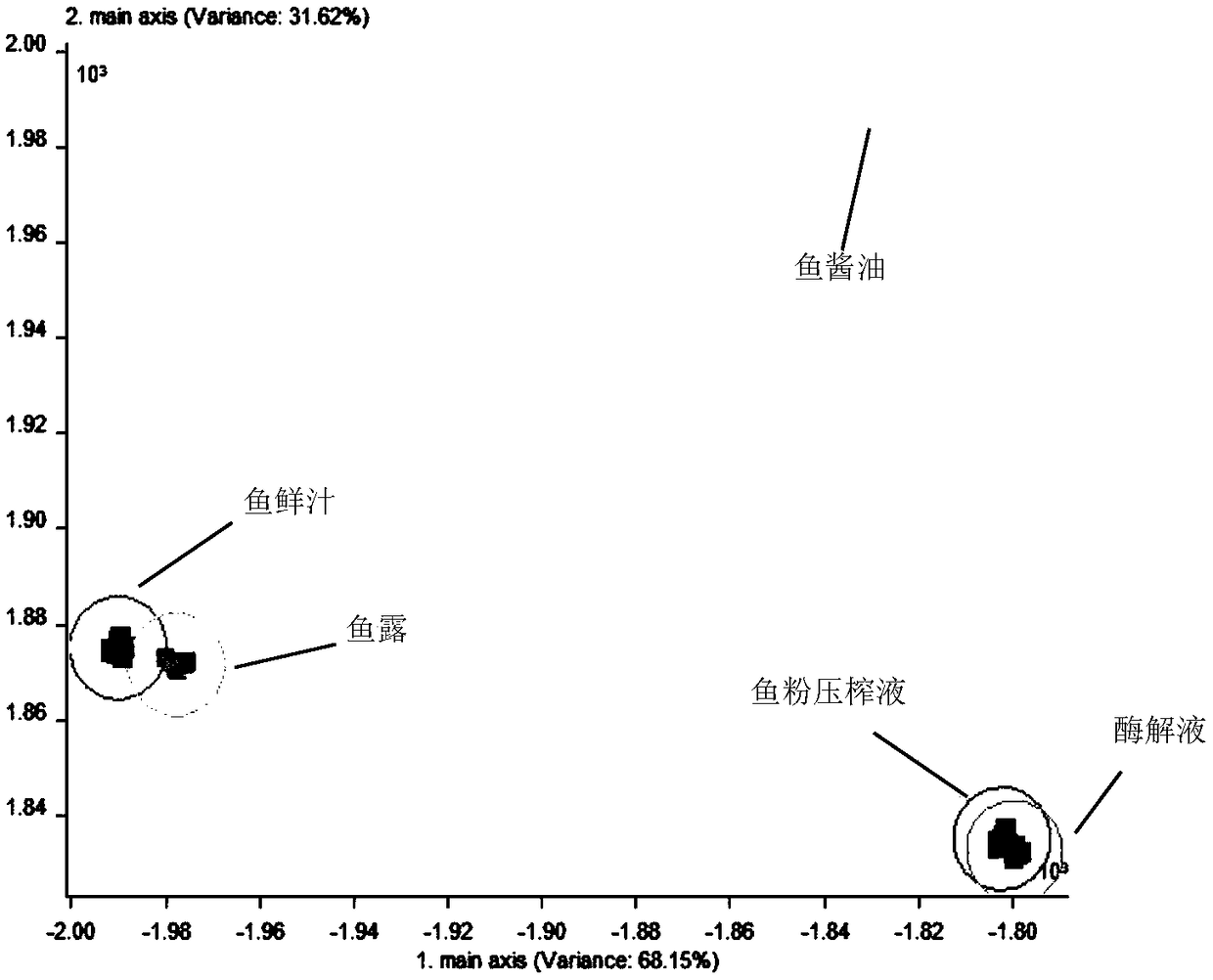

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method for fresh fish juice, comprising the following steps:

[0029] (1) Enzymolysis: Take an appropriate amount of fish meal to process the squeeze liquid, add 0.3% (m / v) compound protease A-1 and 0.2% (m / v) papain, stir to fully dissolve it, and place it in a 60°C refrigerator. On a constant temperature shaker, shake at 110r / min for 5 hours for enzymatic hydrolysis. After the end of the enzymatic hydrolysis, immediately inactivate the enzyme in a 95°C water bath for 15 minutes.

[0030] (2) Koji making: Weigh 133g of soybean meal and 100g of bran, add 180mL of water, mix well, soak for 5 hours, cook and sterilize at 121℃ for 40min, after the sterilization, let the mixed material cool down to about 40℃ , add 2‰ (m / m) strains, mix evenly, spread a layer of sterilized wet gauze on the sieve, transfer the mixture after adding the strains into the sieve, and then cover the sieve with a Layer wet gauze, and finally place the sieve with the material in an inc...

Embodiment 2

[0035] A preparation method for fresh fish juice, comprising the following steps:

[0036] (1) Enzymolysis: Take an appropriate amount of fish meal to process the squeeze liquid, add 0.3% (m / v) compound protease A-1 and 0.2% (m / v) papain, stir to fully dissolve it, and place it in a 60°C refrigerator. On a constant temperature shaker, shake at 110r / min for 5 hours for enzymatic hydrolysis. After the end of the enzymatic hydrolysis, immediately inactivate the enzyme in a 95°C water bath for 15 minutes.

[0037] (2) Koji making: Weigh 155g of soybean meal and 117g of bran, add 240mL of water, mix well, soak for 5h, cook and sterilize at 121°C for 40min, after the sterilization, let the mixed material cool down to about 40°C , add 2‰ (m / m) strains, mix evenly, spread a layer of sterilized wet gauze on the sieve, transfer the mixture after adding the strains into the sieve, and then cover the sieve with a Layer wet gauze, and finally place the sieve with the material in an incuba...

Embodiment 3

[0042] A preparation method for fresh fish juice, comprising the following steps:

[0043] (1) Enzymolysis: Take an appropriate amount of fish meal to process the squeeze liquid, add 0.3% (m / v) compound protease A-1 and 0.2% (m / v) papain, stir to fully dissolve it, and place it in a 60°C refrigerator. On a constant temperature shaker, shake at 110r / min for 5 hours for enzymatic hydrolysis. After the end of the enzymatic hydrolysis, immediately inactivate the enzyme in a 95°C water bath for 15 minutes.

[0044] (2) Koji making: Weigh 150g of soybean meal and 100g of bran, add 220mL of water, mix well, soak for 5 hours, cook and sterilize at 121°C for 40 minutes, after the sterilization, let the mixed material cool down to about 40°C , add 2‰ (m / m) strains, mix evenly, spread a layer of sterilized wet gauze on the sieve, transfer the mixture after adding the strains into the sieve, and then cover the sieve with a Layer wet gauze, and finally place the sieve with the material in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com