Epoxy chloropropane modified chitosan for adsorbing heavy metal ions and preparation method thereof

A technology for epichlorohydrin and heavy metal adsorption, which is applied in the direction of alkali metal oxides/hydroxides, alkali metal compounds, chemical instruments and methods, etc., and can solve the problems of low regeneration rate of active substances, insufficient water removal concentration, Consumption of large energy and other issues to achieve the effect of improving mechanical properties and stability, improving adsorption and selectivity, and broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

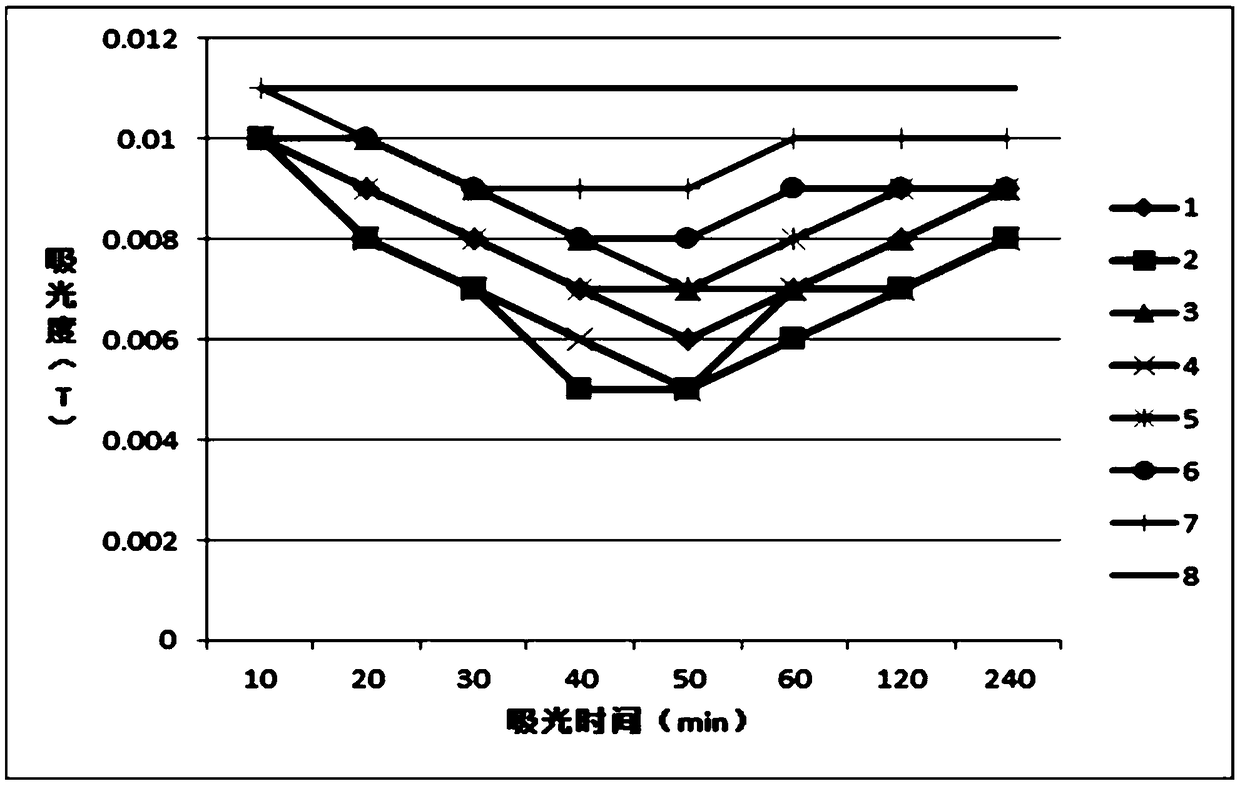

Image

Examples

preparation example Construction

[0015] A preparation method for epichlorohydrin modified chitosan for adsorbing heavy metal ions, comprising: using acetic acid solution, chitosan, epichlorohydrin and NaOH solution according to the addition ratio of 100ml:0.51-0.52g:2.8 -3.2ml:24-26ml for compounding; further, the addition ratio is 100ml:0.51-0.52g:3ml:25ml.

[0016] It should be noted that the reaction principle in this embodiment is as follows: the carbon-chlorine bond on the epichlorohydrin breaks to form C + , and condense with the hydroxyl group in chitosan to obtain an ether; at the same time, the epoxy ring at the other end is opened, and another hydroxyl group in chitosan forms an ether to generate chitosan with a cross-linked structure. The cross-linking reaction between epichlorohydrin and chitosan not only improves the mechanical properties of chitosan itself, but also incorporates active groups to change the activity. By controlling the cross-linking point, the epichlorohydrin can be cross-linked...

Embodiment 1

[0026] The present embodiment provides a kind of preparation method of the epichlorohydrin modified chitosan that is used to adsorb heavy metal ions, comprising:

[0027] At 50°C, add 100ml of 3% acetic acid solution to 0.5008g of chitosan until the chitosan is completely dissolved to form a chitosan solution; add 3ml of epichlorohydrin dropwise to the chitosan solution to form Mixed solution; after reacting for 30 minutes, add 25ml of 5% NaOH solution dropwise to the mixed solution until no white precipitate is formed, cool to 20-30°C, wash twice with distilled water, then filter with acetone Wash twice, filter and dry.

Embodiment 2

[0029] The present embodiment provides a kind of preparation method of the epichlorohydrin modified chitosan that is used to adsorb heavy metal ions, comprising:

[0030] At 50°C, add 100ml of 3% acetic acid solution to 0.5108g of chitosan until the chitosan is completely dissolved to form a chitosan solution; add 3ml of epichlorohydrin dropwise to the chitosan solution to form Mixed solution; after reacting for 30 minutes, add 25ml of 5% NaOH solution dropwise to the mixed solution until no white precipitate is formed, cool to 20-30°C, wash twice with distilled water, then filter with acetone Wash twice, filter and dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com