An energy control method for reducing warpage in laser bending of thin metal plates

A metal sheet, bending forming technology, applied in the field of energy regulation to reduce the warpage of metal sheet laser bending, can solve the problems of large edge warpage, warping deformation, high temperature melting of the sheet surface, etc., to meet the technical requirements Requirements, effect of reducing warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

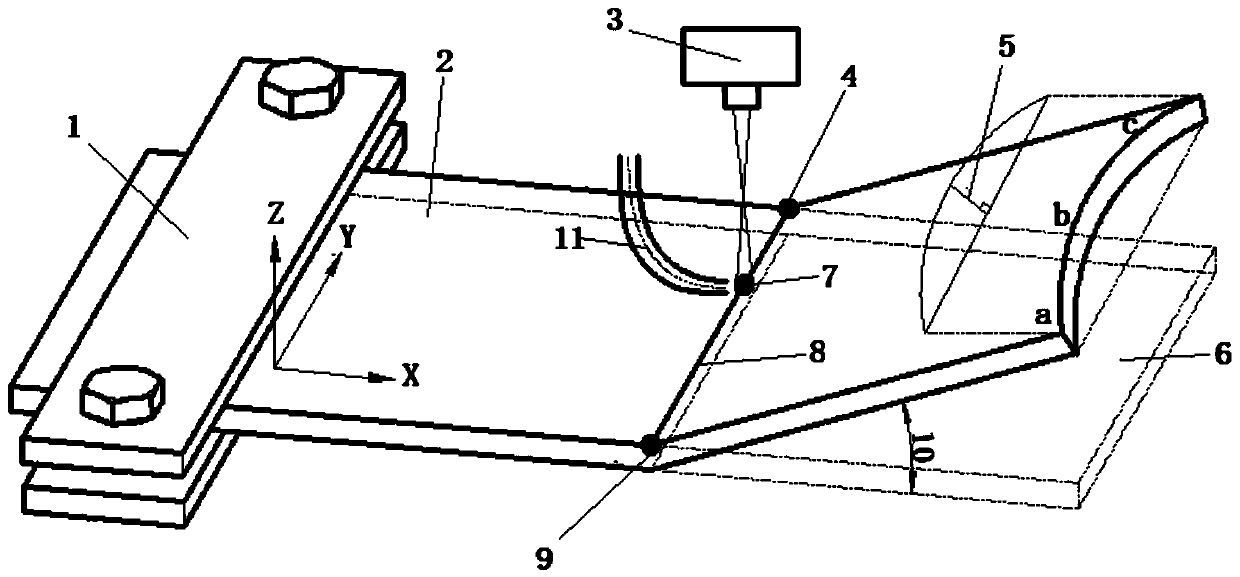

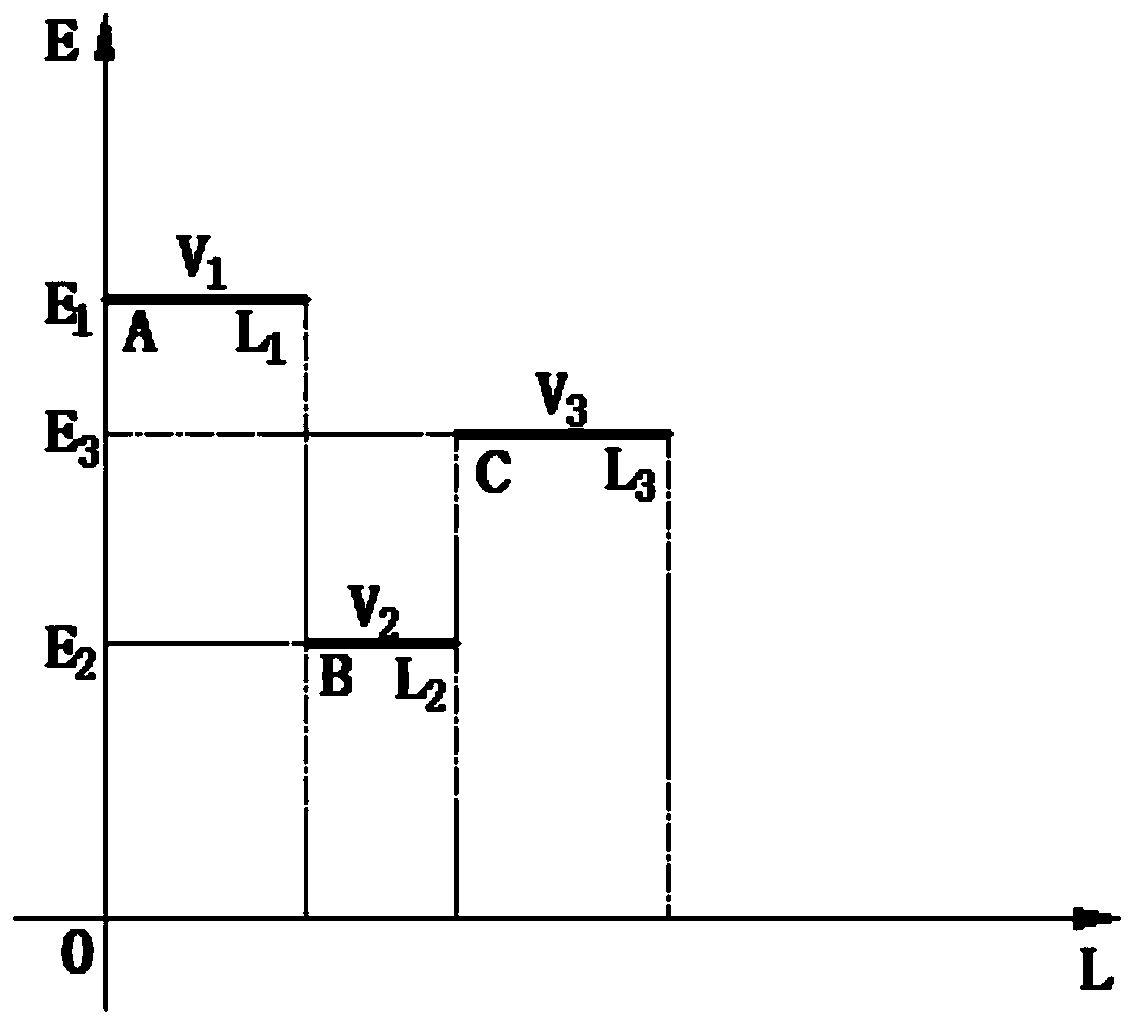

[0024] Embodiment: Laser linear scanning of copper-steel laminated plate warpage correction sample.

[0025] (1) Production of uncorrected samples:

[0026] ① The material of the metal sheet 2 is copper-steel laminated board. Use a shearing machine to cut the copper-steel laminated board with a thickness of 1 mm into a rectangular sample with a width of 70 mm and a length of 100 mm. In order to increase the light absorption rate, use carbon black treatment;

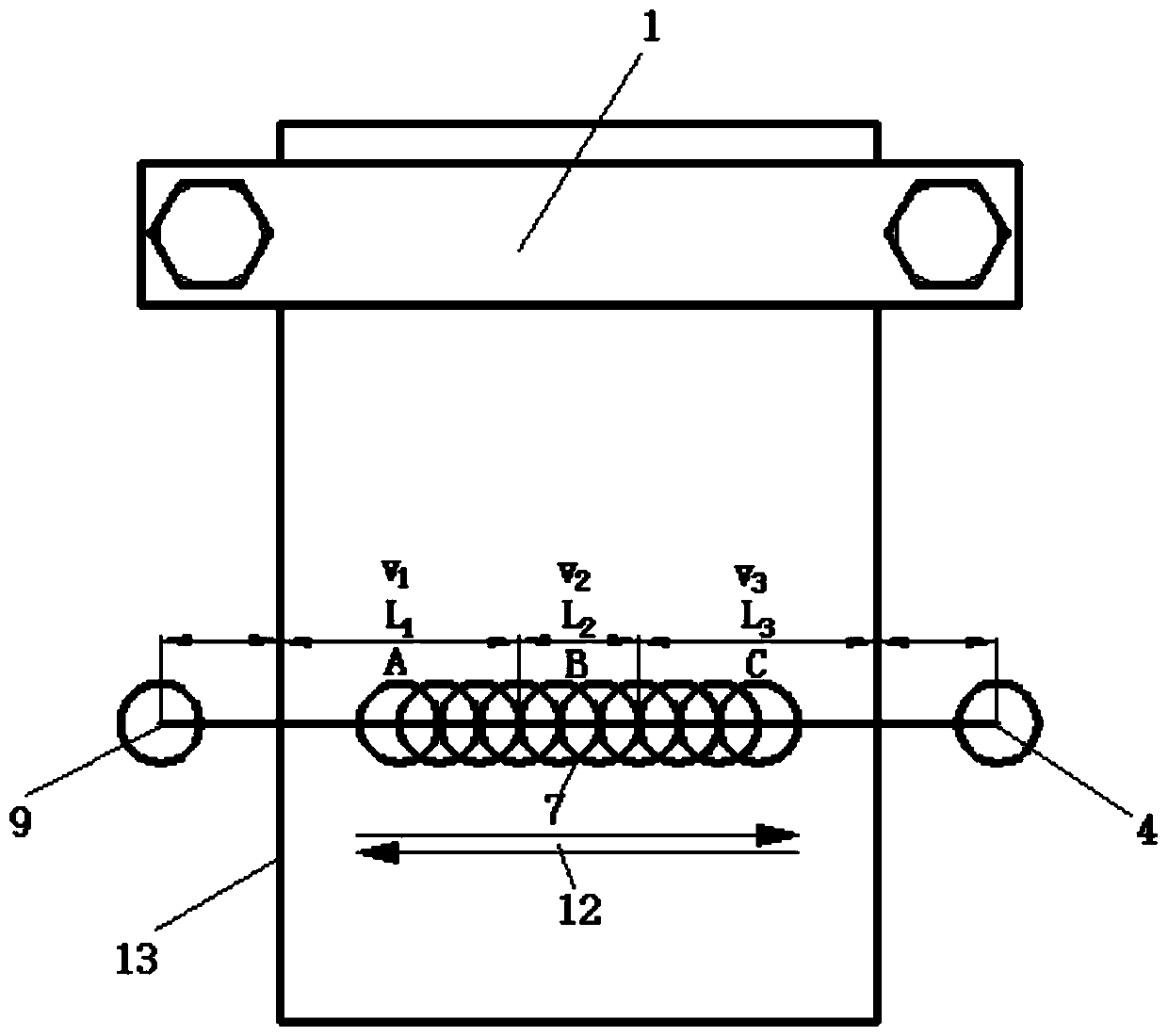

[0027] ② Use the clamping plate 1 to clamp one end of the sample and place it on the laser processing workbench, adjust the laser power to 100w, the frequency to 40Hz, the pulse width to 2ms, the laser scanning speed to 400mm / min, and the defocus to 8mm; figure 2 As shown, the distance 13 between the scanning line and the free end is 25 mm. Here, reciprocating scanning 12 is performed from the position of the scanning starting point 9. In order to stabilize the laser light source during sample processing, a section of i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com