Aisotropic electro-shape memory polymer microlayer composite material

A composite material and polymer technology, applied in the field of functional polymer composite materials and their preparation, can solve the problems of small adjustable range of shape memory performance, difficult control of shape recovery process, inability to achieve anisotropy, etc. Mass production, easy promotion and application, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

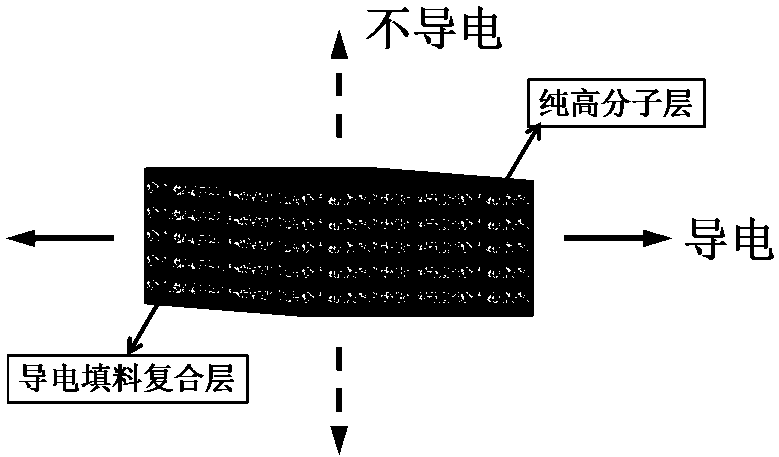

Method used

Image

Examples

Embodiment 1

[0045] After the polycaprolactone (PCL) pellets and carbon black (CB) powder are physically and mechanically mixed according to the mass ratio of 70:30, after being melted, extruded and granulated by a twin-screw extruder, they are mixed with polyolefin Elastomer ethylene-octene copolymer (POE) pellets are put into the two extruders of the micro-layer co-extrusion device respectively, the speed ratio of the extruders is 1:l, and the temperature of each section of the extruder is controlled at 70-200 ℃, the temperature of the confluence, the split stacking unit and the die is about 200 °C, and 3 split stacking units are used. POE and PCL blended with CB are melted and plasticized by the extruder, combined in the confluence, cut and re-stacked in sequence by the split and superimposed units, flow out of the die, and cooled by the cooling roll and the winding roll. Traction, the POE / PCL / CB multilayer shape memory polymer material with 16 layers was prepared. The thermal response...

Embodiment 2

[0047] After the polyolefin elastomer ethylene-octene copolymer (POE) pellets and carbon black (CB) powder are physically and mechanically mixed according to the mass ratio of 70:30, they are melted, extruded and pelletized by a twin-screw extruder , put it and polycaprolactone (PCL) pellets into two extruders of the micro-layer co-extrusion device respectively, the others are the same as in Example 1, the shape memory performance, volume conductivity and electrical recovery rate of the obtained material are the same as Embodiment 1 is basically the same.

Embodiment 3

[0049] Others are the same as in Example 1, and the speed ratio of the extruder is 1:3. The thermal response temperature range of the obtained POE / PCL / CB shape memory polymer material is 50-80°C, the shape recovery rate is over 90%, and the shape fixation rate is over 80%. The volume conductivity parallel to the layer direction can reach 12Ω / cm, and the electrical recovery rate is above 85%; the volume conductivity perpendicular to the layer direction is infinite, and the electrical recovery rate is 0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk conductivity | aaaaa | aaaaa |

| Bulk conductivity | aaaaa | aaaaa |

| Bulk conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com