All-electric mine car transport system

A transportation system and pure electric technology, applied in the field of electric drive mining vehicles, can solve problems such as troublesome plugging and unplugging, safety, and hidden dangers, and achieve the effects of light weight, three-phase load balance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

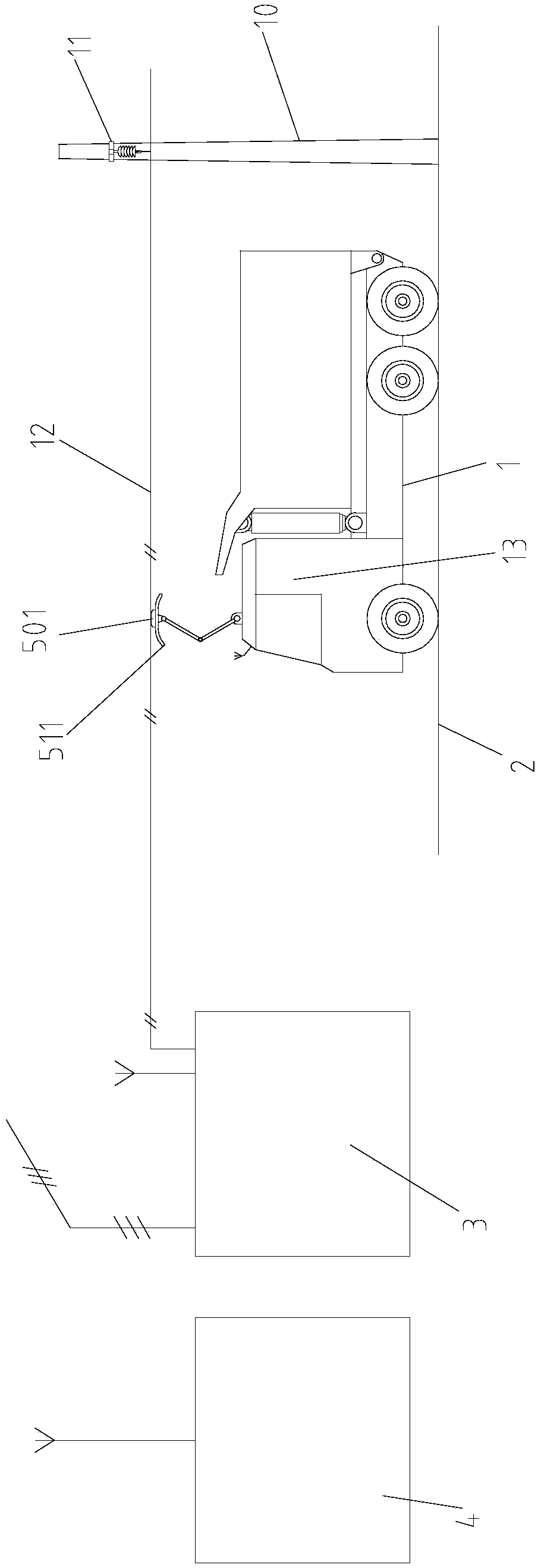

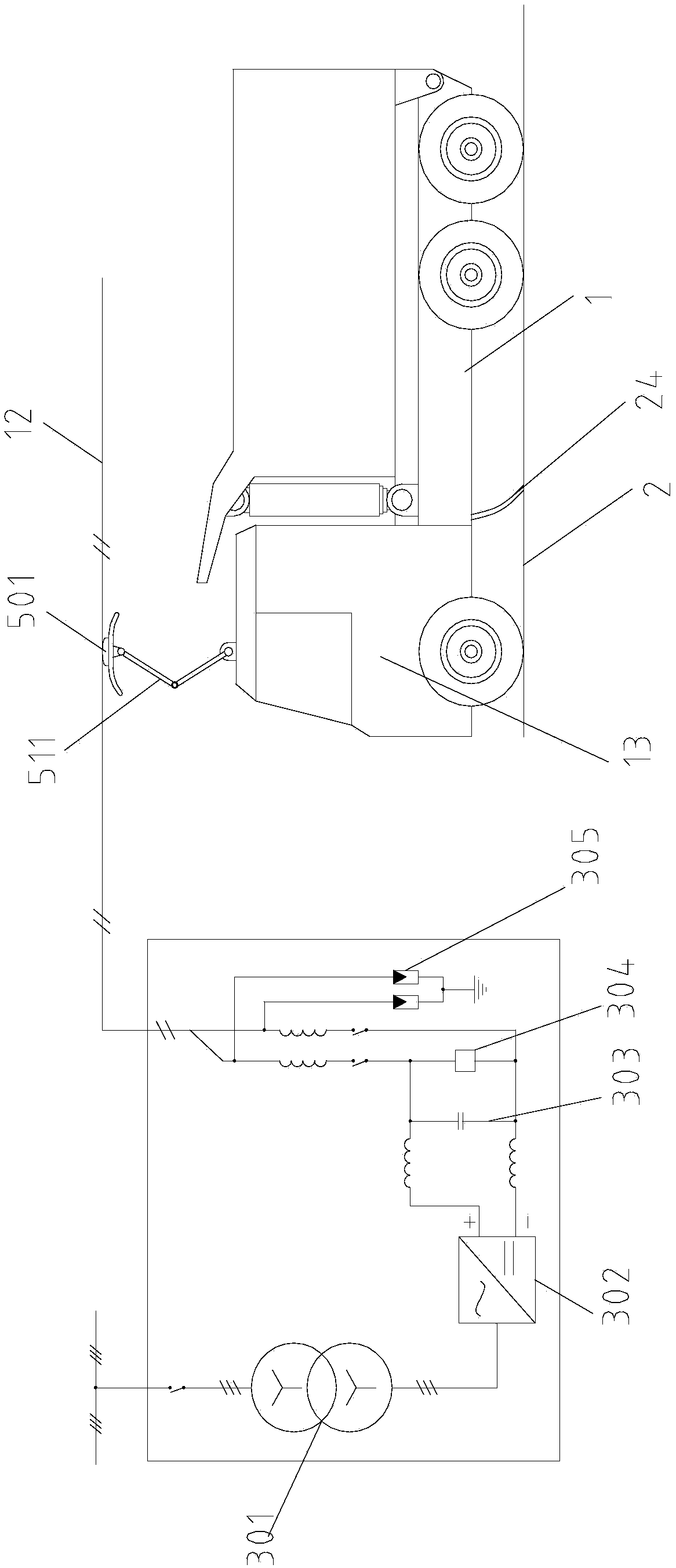

[0039] Attached below Figure 1-8 A first embodiment of the present invention will be described.

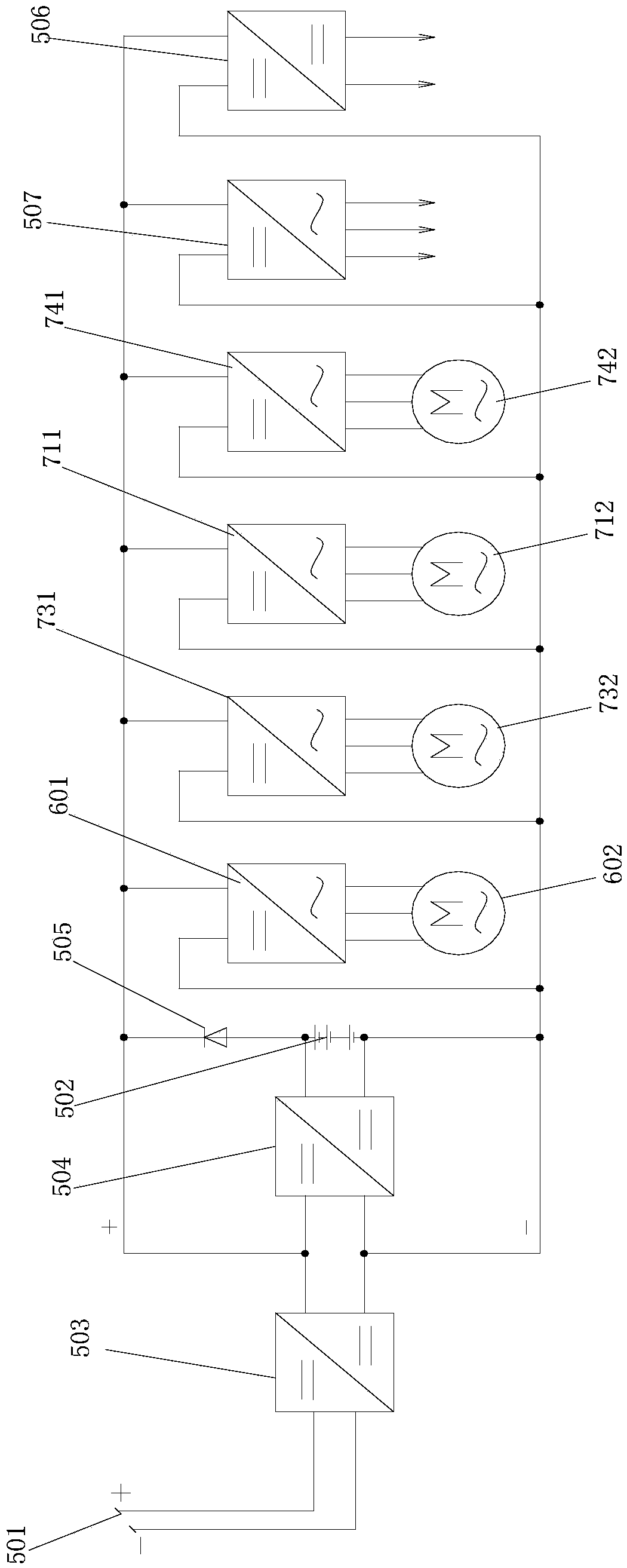

[0040] The pure electric mine car transportation system includes an electric mine car 1, a special driveway 2, a converter station 3 and a real-time monitoring center 4. A plurality of electric poles 10 are buried on the special driveway 2 and are arranged on a horizontal horizontal line at the upper end of the electric poles 10. The pole 11 is provided with a medium-voltage DC catenary 12 with a voltage range of 4.2kV to 50kV, and the electric mine car 1 is provided with a dual power supply mode power supply part 5, a walking part 6, an auxiliary function part 7, and a vehicle controller 8 and the wireless communication system 9, and the vehicle controller 8 is connected with the dual power supply mode power supply part 5, the walking part 6, the auxiliary function part 7 and the wireless communication system 9 through the CAN bus, and the vehicle controller 8 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com