Energy-storage workover rig

A technology for workover rigs and energy storage, which is applied in drilling equipment, electric vehicles, drilling equipment and methods, etc. It can solve the problems of unable to meet the power requirements such as hook load and hook speed, and limit the flexibility and approval time of electric drive workover rigs. Electricity connection hazards and other problems can be solved to achieve the effect of solving the problem of domestic electricity consumption, realizing the convenience of operation and rationalizing the layout mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

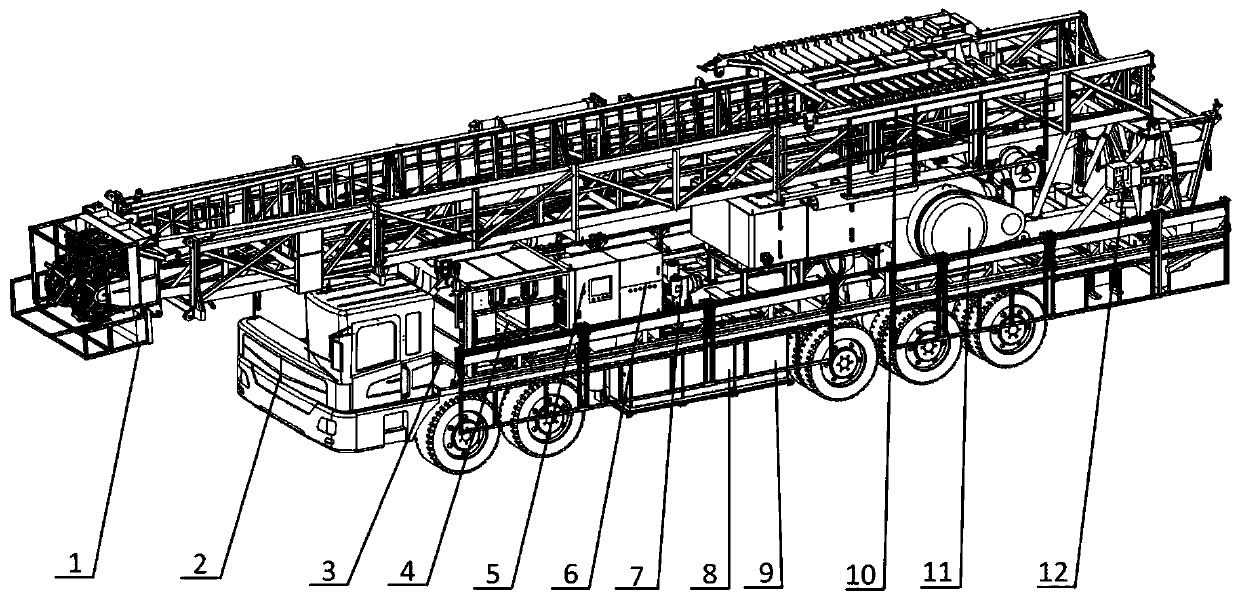

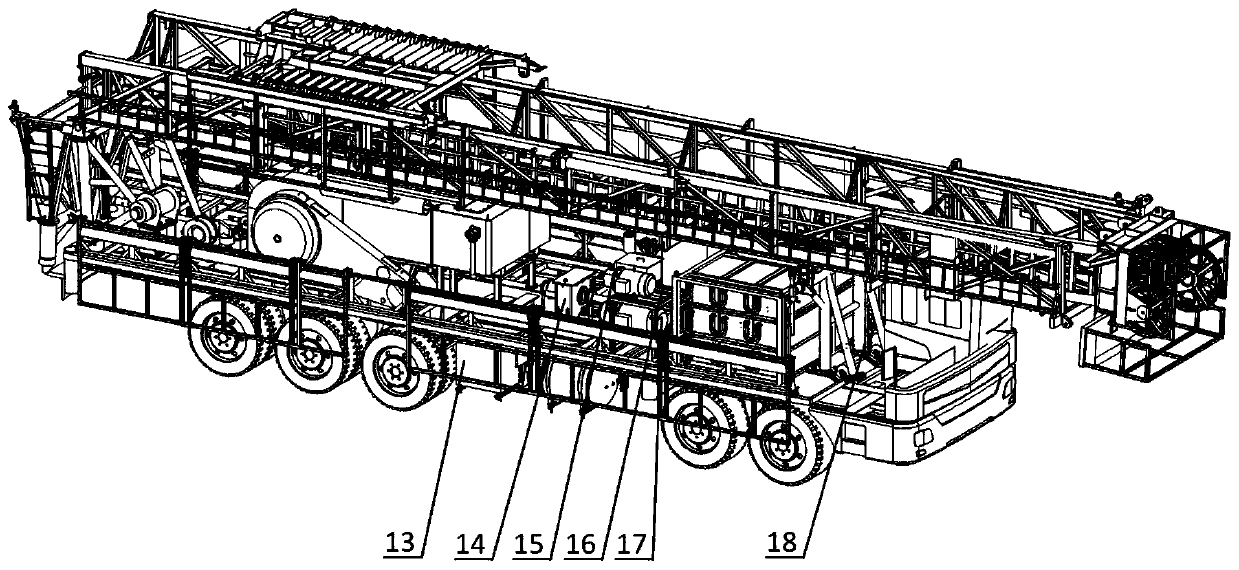

[0032] Such as Figures 1 to 2 Shown is an energy storage workover rig, the energy storage workover rig includes a battery module 4 , and the battery module 4 is used to supply power for the workover operation and chassis travel of the energy storage workover rig. The energy storage workover rig can use the potential energy released during the workover operation to charge the battery module 4 and the kinetic energy of the energy storage workover rig to charge the battery module 4 during walking. The voltage range of the battery module: 400V ~ 800V, the charge and discharge power is not less than 315KW, the power is not less than 140KWh, the application environment temperature is -20°C ~ +45°C, the discharge current is not less than 400A, and it supports the charging and discharging mode. The charging power is not less than 50KW. Through charging and discharging of the battery module, the potential energy released during the workover operation and the kinetic energy during wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com