Rotary-cut assembly line capable of identifying round logs with high precision

A high-precision, streamlined technology, used in the manufacture of veneer chips, wood processing appliances, manufacturing tools, etc., can solve the problems of low rotary cutting accuracy, reduce the shaking amplitude of the root end, and high cost, and achieve anti-deformation and wear resistance. Strong, reduce the shaking amplitude, improve the effect of rotary cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

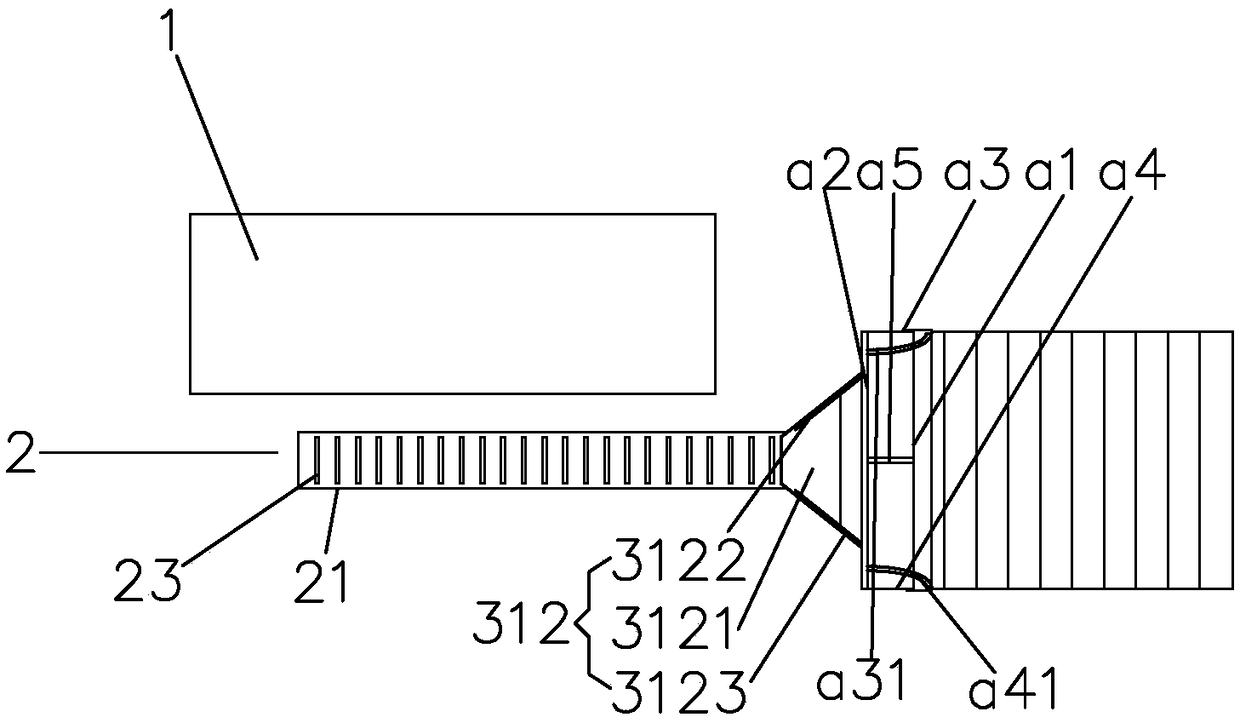

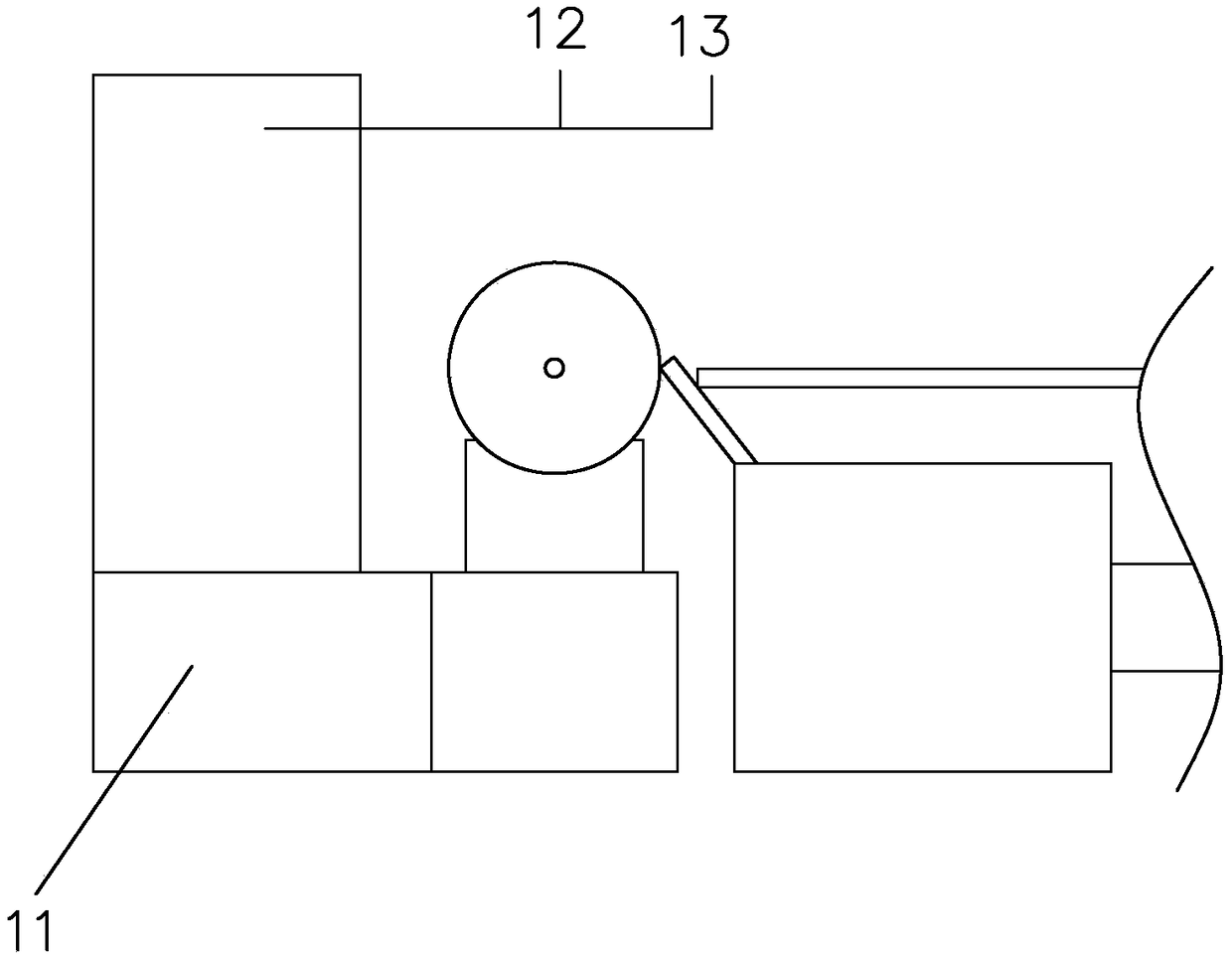

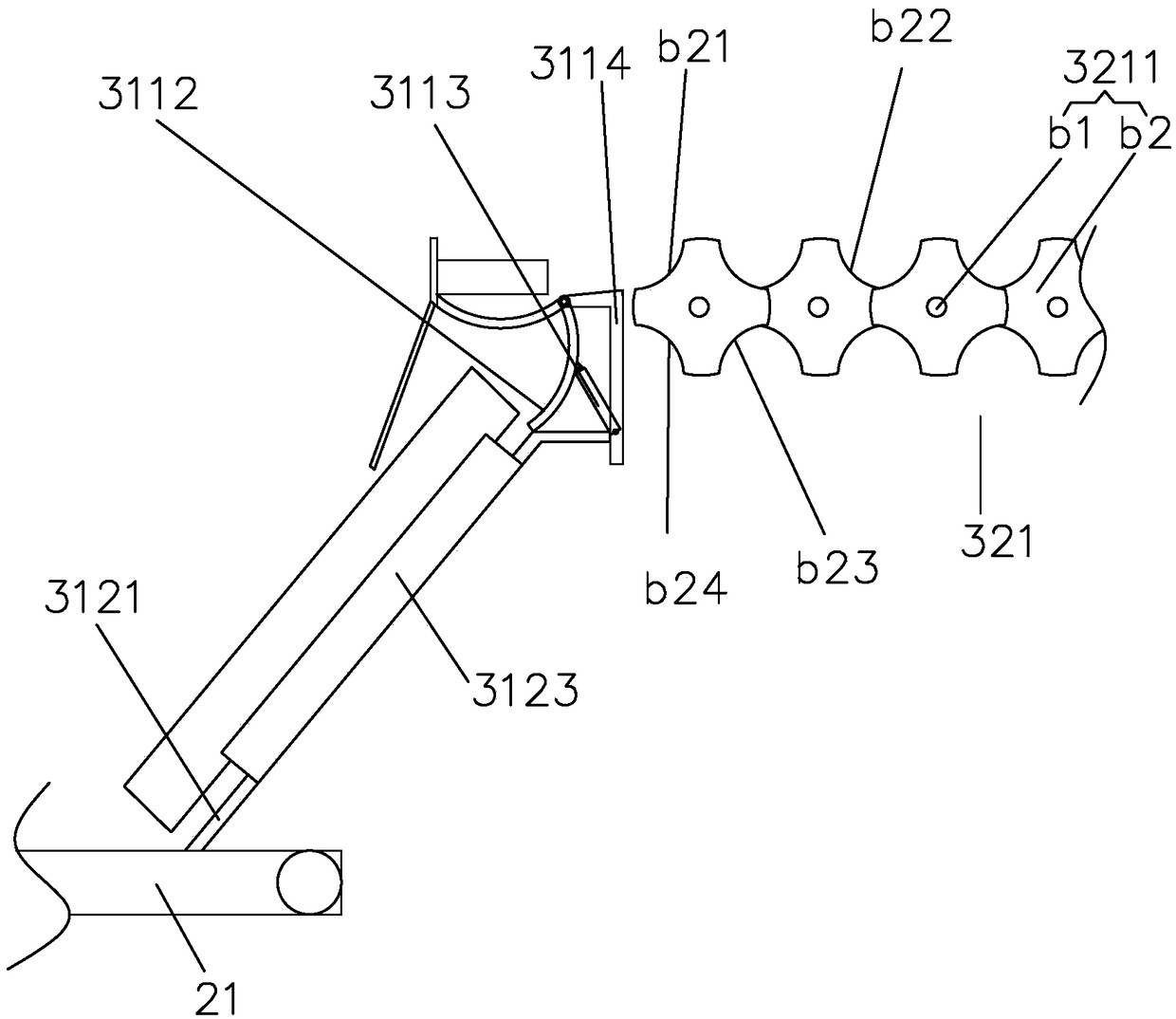

[0048] A high-precision identification log rotary cutting line of the present invention, such as Figures 1 to 15 Shown, comprise rotary cutting part 1, carry out the feed part 2 that supplies round wood to rotary cutting part 1, and carry out the delivery part that conveys round wood to feeding part 2; Rotary cutting part 1 comprises frame 11, and is located at The rotary cutting mechanism 12 and the positioning and rotating mechanism 13 on the frame 11; also include the controller that controls the rotary cutting part 1, the feeding part 2 and the conveying part; the positioning and rotating mechanism 13 includes the root end of the root end of the corresponding log Clamping shaft, and the tip end clamping shaft corresponding to the treetop end of the log; the feeding part 2 includes a feeding conveyor belt 21 that transports the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com