Electric flocculation device for disposing industrial wastewater difficult to biodegrade

A technology for refractory biodegradation and industrial wastewater, applied in the application of industrial wastewater treatment, the field of electroflocculation treatment of refractory biodegradable industrial wastewater, which can solve the problem of the passivation concentration polarization degree on the surface of the electrode plate and the inconsistency of the current utilization rate of the reaction device. It can improve the passivation and concentration polarization of the anode surface, improve the electron transfer rate, and achieve better treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings. Those skilled in the art should understand that the implementation cases described here are only used to explain the present invention and should not limit the protection scope of the present invention.

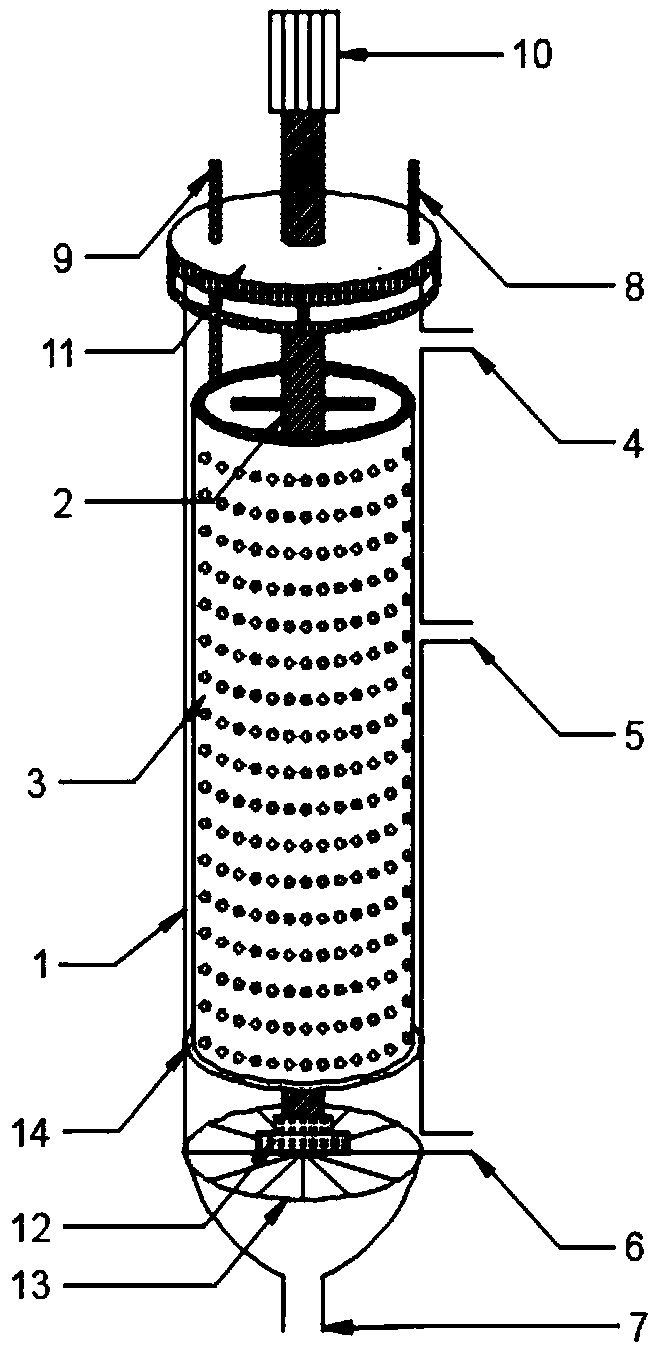

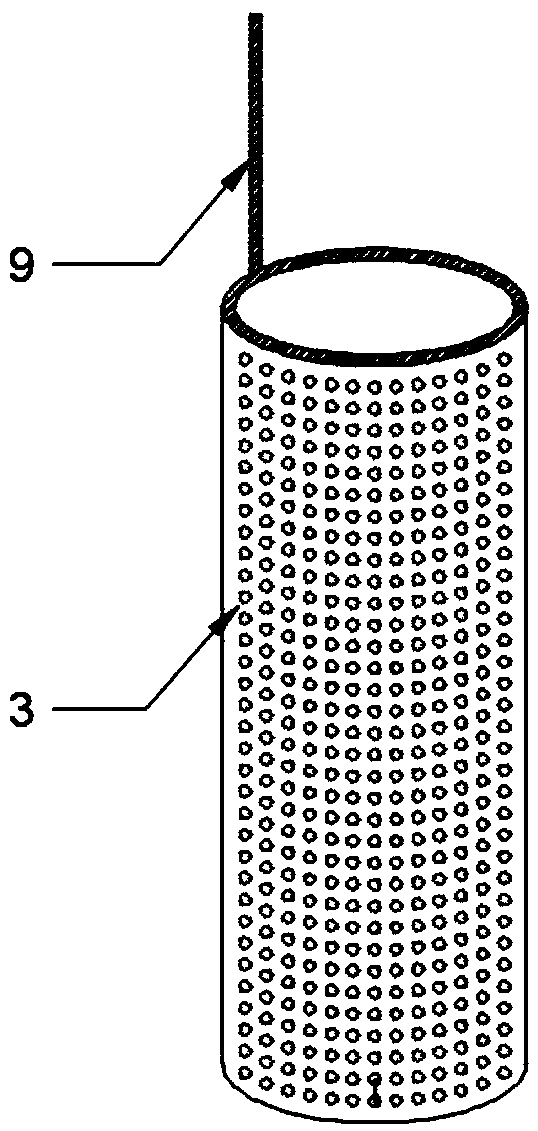

[0022] see figure 1 As shown, the present invention provides a device for electrocoagulation treatment of refractory biodegradable industrial wastewater, comprising a vertical settling tank (1), a rotating motor (10), a rotating anode (2), a porous hollow columnar cathode (3), a rotating Anode shaft fixing flange (11), rotating anode bottom support bearing (12), cathode bottom hollow support tray (14), bottom bearing support tray (13), rotating anode conductive column (8), cathode conductive column (9), Water inlet (4), monitoring sampling port (5), water outlet (6) and sewage outlet (7).

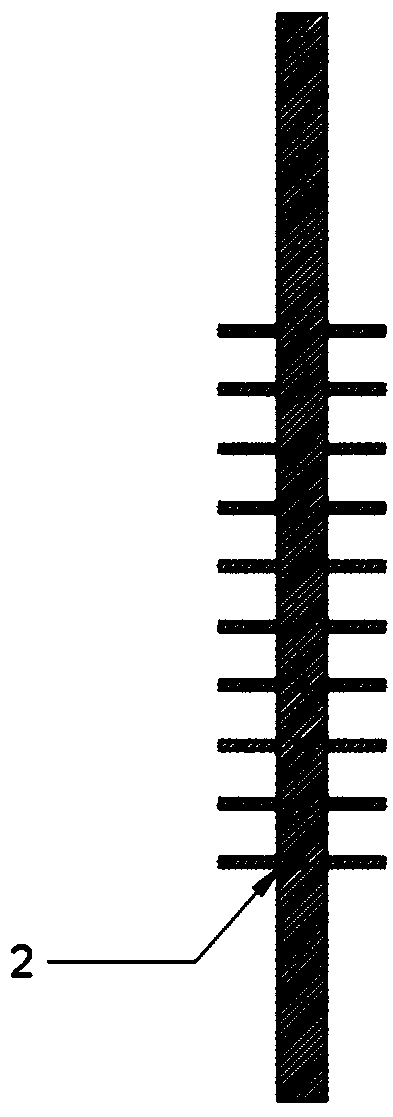

[0023] see Figure 1-3 As shown, the columnar upper end and the bottom end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com