A modified spiral nano-carbon fiber and its preparation method and application, a rubber composite material

A technology of nano-carbon fiber and helix, which is applied in the field of preparation of inorganic non-metallic materials, and can solve problems such as difficult bonding, reinforcement effect to be improved, and easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention has no special limitation on the preparation method of the above-mentioned rubber composite material, and the preparation method of the rubber composite material well-known to those skilled in the art can be used.

[0044] The elongation at break of the rubber composite material using the modified helical nano-carbon fiber material of the present invention is 13.4% higher than that of the rubber composite material using the unmodified helical nano-carbon fiber material.

Embodiment 1

[0047] A method for modifying helical carbon nanofibers, comprising the following steps:

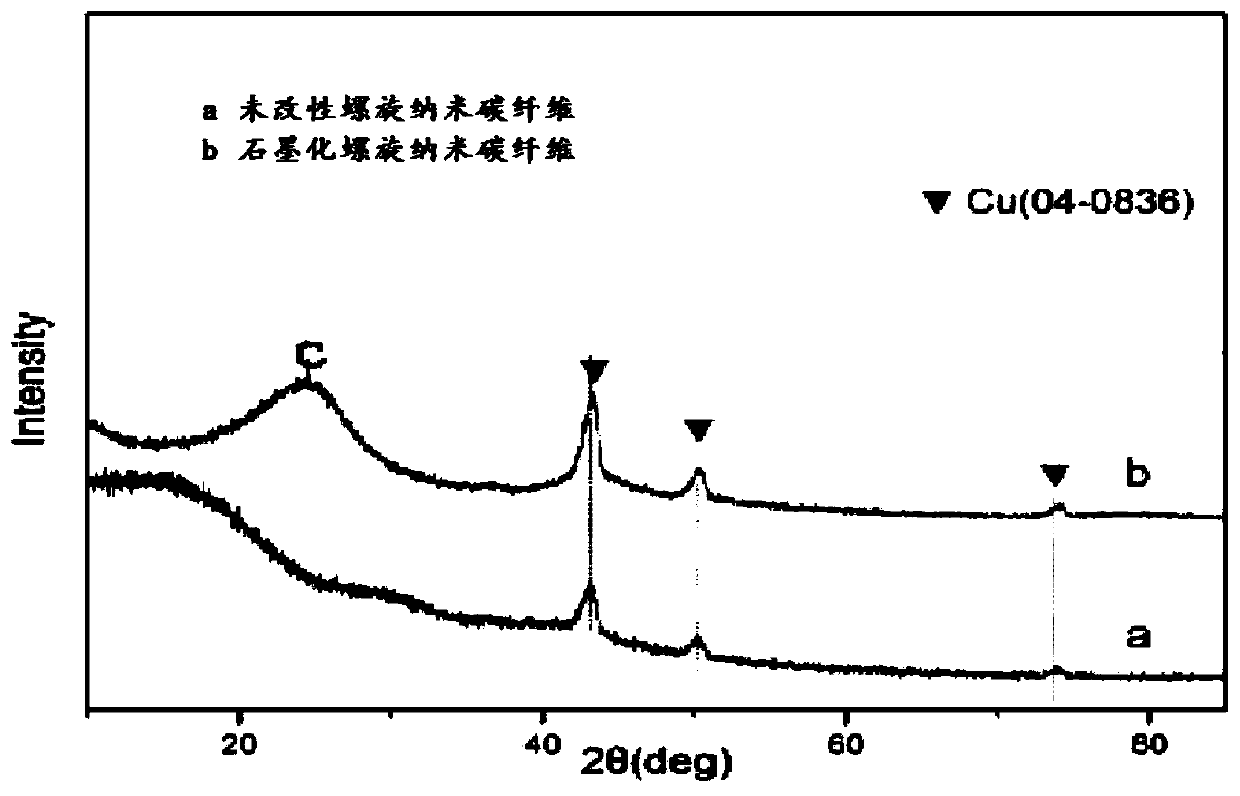

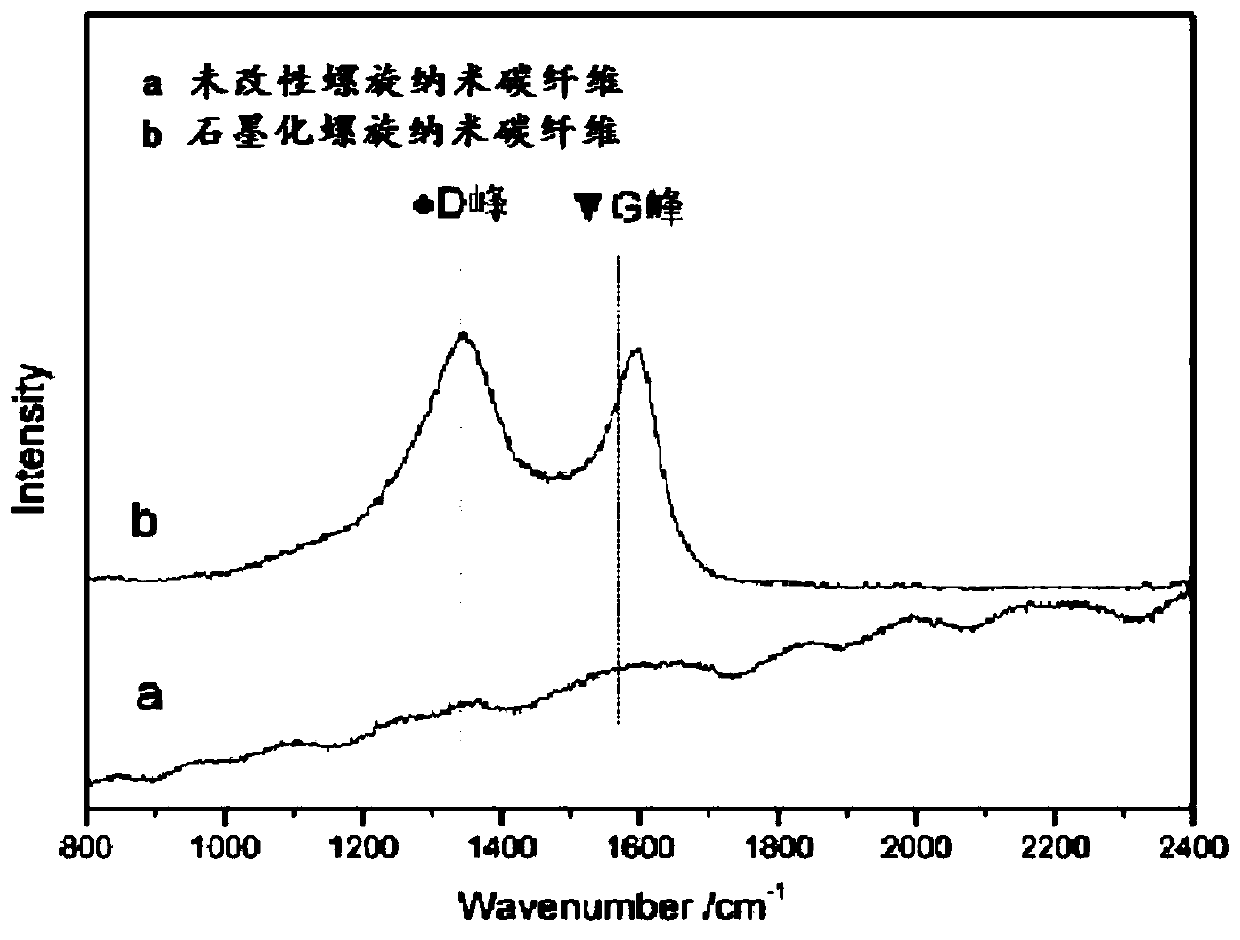

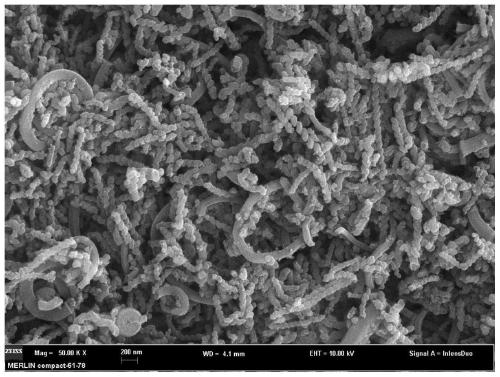

[0048] (1) 5g spiral nano-carbon fibers are placed in a graphite crucible, sealed with a graphite lid and placed in a vacuum carbon tube furnace; vacuumize to 10 -3 Pa, from room temperature to 1000°C, then heat-treated for 2h, and cooled to room temperature to obtain a graphitized helical nano-carbon fiber material; the heating rate is 8°C / min;

[0049] (2) Mix the graphitized spiral nano-carbon fiber with 150g stainless steel balls and 150mL absolute ethanol in a ball milling tank, place the ball milling tank in a ball mill for ball milling; the speed of ball milling is 200r / min, and the time of ball milling is 4 hours. The mixture was dried in a drying oven at 70°C for 12 hours, then taken out and passed through a 100-mesh sieve to obtain ball-milled helical carbon nanofibers;

[0050] (3) Weigh 5g of ball-milled spiral nano-carbon fiber and place it in a three-necked flask, add 300m...

Embodiment 2

[0057] A method for modifying helical carbon nanofibers, comprising the following steps:

[0058] (1) 5g spiral nano-carbon fibers are placed in a graphite crucible, sealed with a graphite lid and placed in a vacuum carbon tube furnace; vacuumize to 10 -3 Pa, from room temperature to 800°C, then heat-treated for 4h, and cooled to room temperature to obtain graphitized helical nano-carbon fiber material; the heating rate is 9°C / min;

[0059] (2) Mix the graphitized spiral nano-carbon fiber with 150g stainless steel balls and 150mL absolute ethanol in a ball milling jar, place the ball milling jar in a ball mill and carry out ball milling; the rotating speed of ball milling is 400r / min, and the time of ball milling is 8 hours. The mixture was dried in a drying oven at 70°C for 12 hours, then taken out and passed through a 100-mesh sieve to obtain ball-milled helical carbon nanofibers;

[0060] (3) Weigh 5g of ball-milled spiral nano-carbon fiber and place it in a three-necked f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com