Carbon nanotube/birnessite/graphene composite positive electrode material with hierarchical structure, preparation method and application

A graphene composite, carbon nanotube technology, applied in positive electrodes, structural parts, battery electrodes, etc., can solve problems such as poor performance of manganese dioxide electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A method for preparing a carbon nanotube / birnessite / graphene composite positive electrode material with a hierarchical structure of the present invention comprises the following steps:

[0031] 1) Disperse a certain mass of surface-treated carbon nanotubes in an aqueous potassium permanganate solution with a concentration of 2-6 mg / mL, and the concentration of carbon nanotubes is 0.5-3 mg / mL;

[0032] The surface treatment method of carbon nanotubes is nitric acid acidification or plasma treatment, which is used to increase the oxygen-containing groups on the surface of carbon nanotubes to improve reactivity and hydrophilicity;

[0033] 2) Stir the mixed dispersion liquid obtained in 1) at room temperature for 1 hour, transfer it to a hydrothermal reaction kettle, keep it warm at 110-130°C for 5-6 hours, and naturally cool to room temperature;

[0034] 3) Centrifuge and wash the product obtained in 2) with deionized water for more than 5 times until the supernatant is n...

Embodiment 1

[0038] 1) Add 200mg of carbon nanotubes into 250mL of 5M nitric acid solution, heat and stir at 80 degrees for reflux for 24 hours, wash with deionized water until neutral, and obtain surface-treated carbon nanotubes after drying;

[0039] 2) Disperse 50 mg of surface-treated carbon nanotubes in 150 mL of 3 mg / mL potassium permanganate solution, stir at room temperature for 1 hour, transfer to three 100 mL hydrothermal reactors, react at 120 ° C for 5 hours, and cool naturally to room temperature;

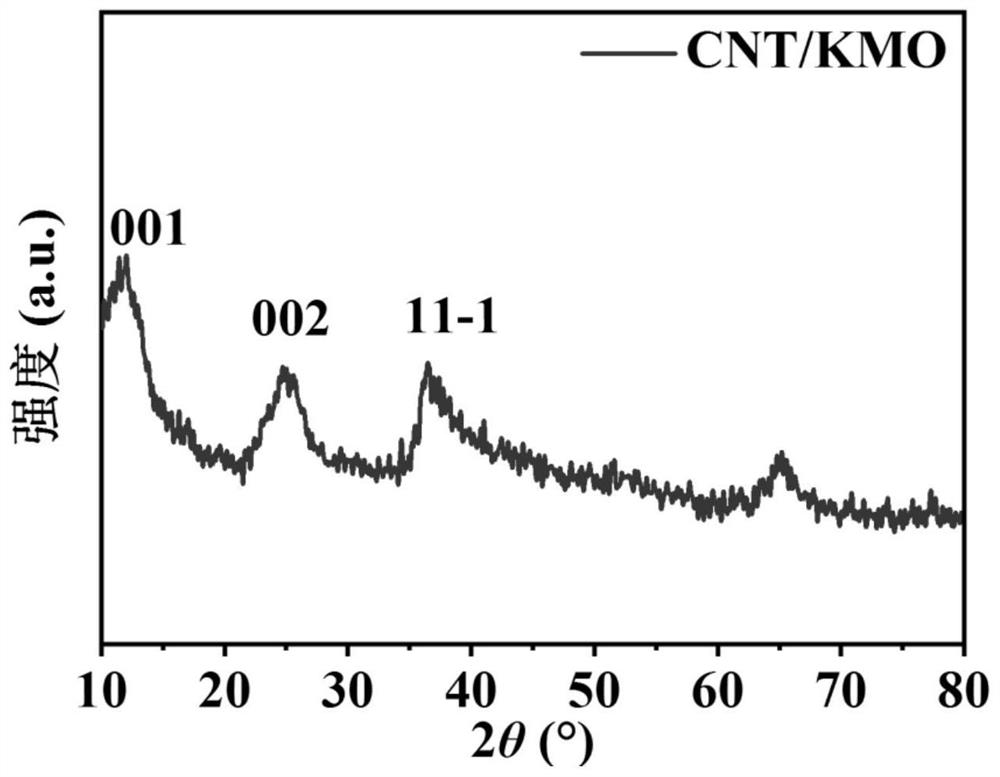

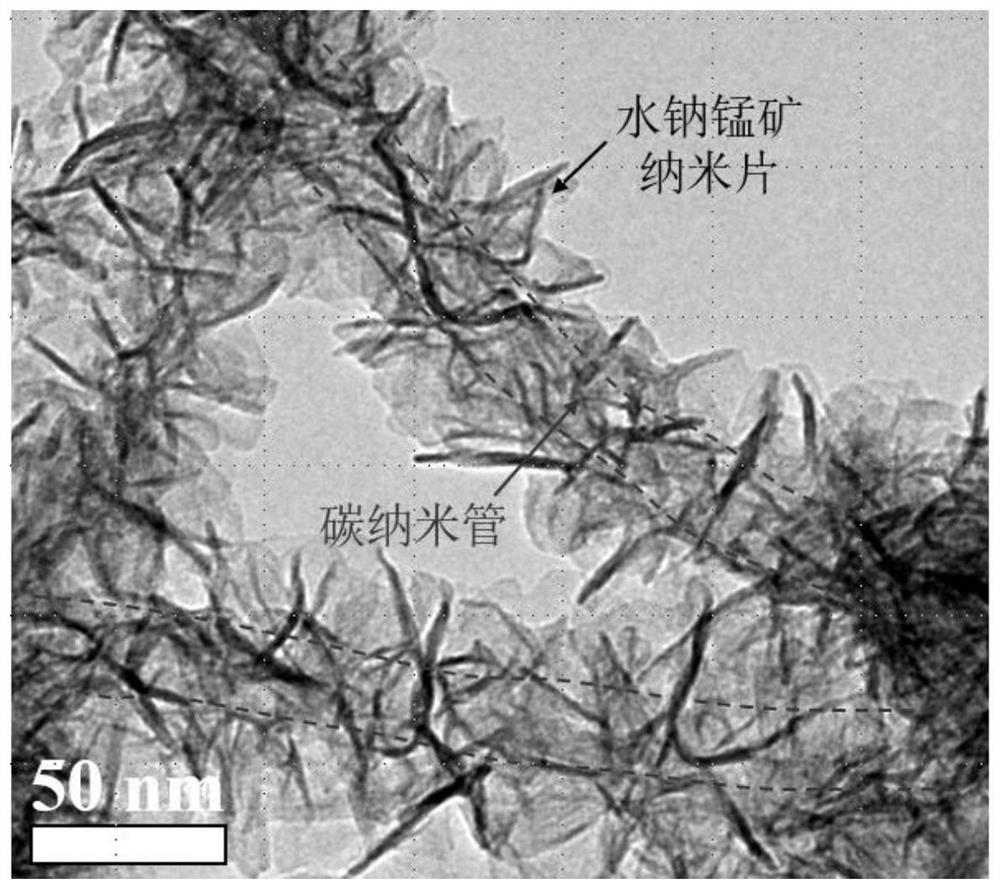

[0040] 3) The product obtained in 2) was centrifuged and washed 7 times with deionized water, and then lyophilized at minus 50°C for 24 hours to obtain a CNT / KMO composite fiber, whose X-ray diffraction pattern was as follows figure 1 , figure 1 It is shown that the obtained material is a birnessite-type manganese dioxide structure, and at the same time from its transmission electron microscope photo figure 2 It can be seen that the core-shell structure of CNT@KMO, in which the ...

Embodiment 2

[0044] 1) Spread the carbon nanotubes on the glass substrate, use oxygen plasma under the condition of 0.3torr and 50W, treat the surface of the carbon nanotubes in the air for 8 minutes, and obtain the surface-treated carbon nanotubes;

[0045] 2) Disperse 60 mg of surface-treated carbon nanotubes in 180 mL of 3 mg / mL potassium permanganate solution, stir at room temperature for 1 hour, transfer to four 100 mL hydrothermal reactors, react at 130 ° C for 6 hours, and then cool naturally to room temperature;

[0046] 3) The product obtained in 2) was centrifuged and washed 8 times with deionized water, and then lyophilized at minus 55°C for 20 hours to obtain CNT / KMO composite fibers;

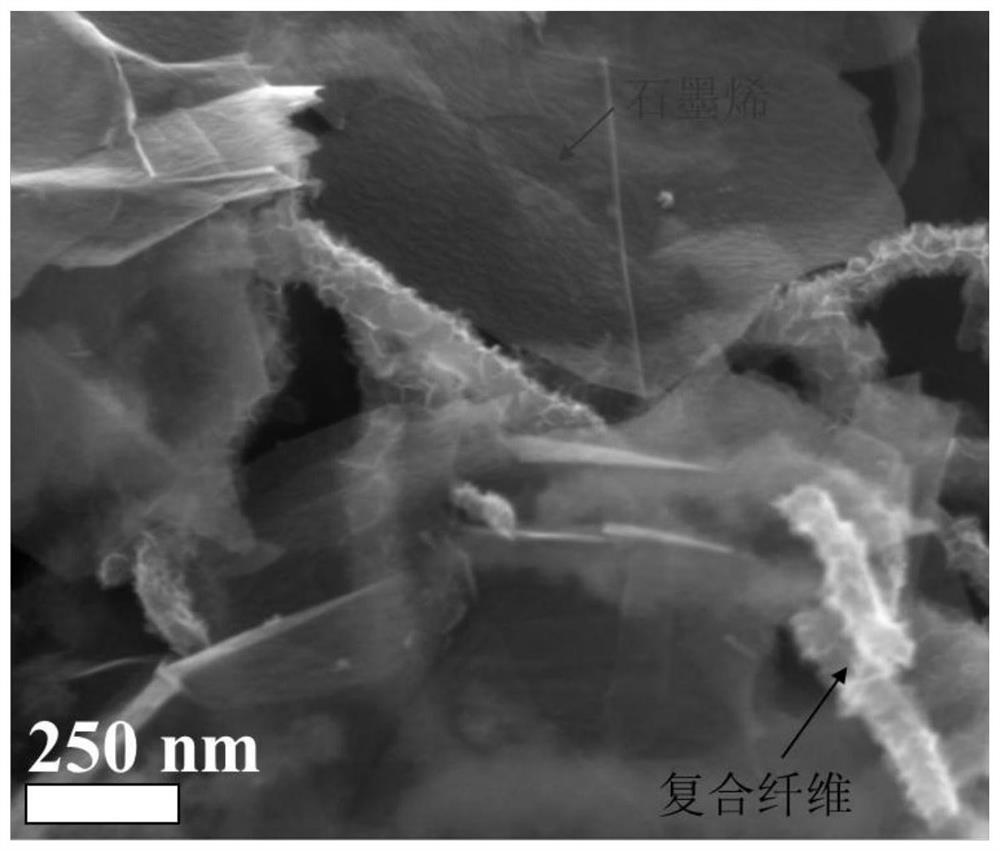

[0047] 4) Disperse 10mg of highly conductive graphene (thickness<3nm) in ethanol and terpineol mixed solution of 30mL 0.67mg / mL ethylcellulose (EC), the volume ratio of ethanol and terpineol is 20: 1. Then add 40 mg of CNT / KMO composite fiber, stir for 0.5 hours, place in an oil bath at 95°C, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com