Broadband emission fluorescent powder material and preparation method thereof

A phosphor and broadband technology, which is applied in the field of broadband emitting phosphor materials and their preparation, can solve the problems of less research on solid luminescent materials, and achieve the effects of easy operation and mass production, simple preparation methods, and wide excitation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A broadband emission phosphor material, the chemical expression of the phosphor is Ca 3 Sc 1.97 Si 3 o 12 : 0.03Cr, its preparation steps are as follows:

[0036] 1. Weigh the raw material CaCO 3 9mmol, Sc 2 o 3 2.955mol, SiO 2 9mmol, Cr 2 o 3 0.045mmol;

[0037] 2. Fully mix the weighed raw materials, sinter in air at 1425°C for 2 hours, and cool down to room temperature naturally to obtain a roasted product;

[0038] 3. After fully grinding the obtained roasted product into powder and passing through a 200-mesh sieve, washing with deionized water for 3 times, and drying at 80°C, the Ca 3 Sc 1.97 Si 3 o 12 : 0.03Cr broadband emission phosphor material.

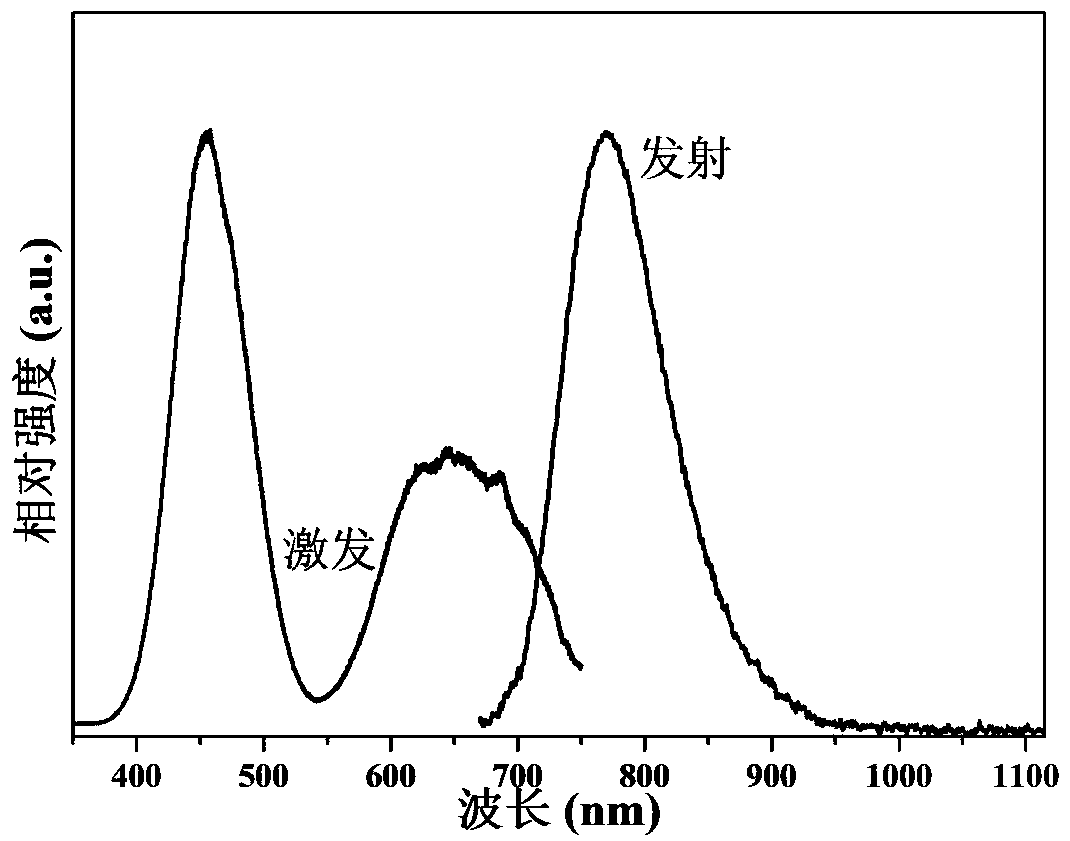

[0039] The excitation spectrum and emission spectrum of the broadband emitting phosphor material prepared in this embodiment are shown in the attached figure 1 shown.

Embodiment 2

[0041] A broadband emission phosphor material, the chemical expression of the phosphor is Ca 3 Sc 1.99 Si 3 o 12 : 0.01Cr, its preparation steps are as follows:

[0042] 1. Weigh the raw material CaCO 3 9mmol, Sc 2 o 3 2.985mol, SiO 2 9mmol, Cr 2 o 3 0.015mmol;

[0043] 2. Fully mix the weighed raw materials, sinter in the air at 1425°C for 1 hour, and naturally cool down to room temperature to obtain a roasted product;

[0044] 3. After fully grinding the obtained roasted product into powder and passing through a 200-mesh sieve, washing with deionized water for 3 times, and drying at 80°C, the Ca 3 Sc 1.99 Si 3 o 12 : 0.01Cr broadband emitting phosphor material.

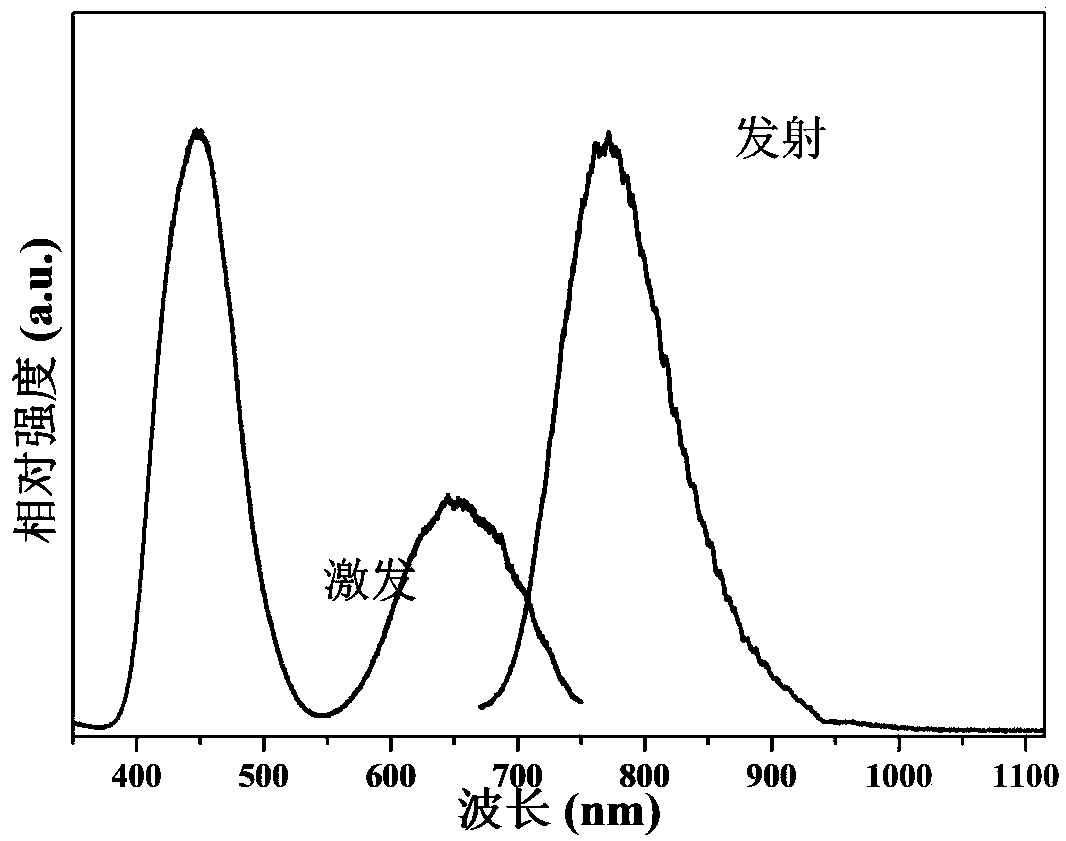

[0045] The excitation spectrum and emission spectrum of the broadband emitting phosphor material prepared in this embodiment are similar to those in Embodiment 1.

Embodiment 3

[0047] A broadband emission phosphor material, the chemical expression of the phosphor is Ca 3 sc 1.9 Si 3 o 12 : 0.1Cr, its preparation steps are as follows:

[0048] 1. Weigh the raw material CaCO 3 9mmol, Sc 2 o 3 2.85mol, SiO 2 9mmol, Cr 2 o 3 0.15mmol;

[0049] 2. Fully mix the weighed raw materials, sinter in the air at 1425°C for 2 hours, and naturally cool down to room temperature to obtain a roasted product;

[0050] 3. Fully grind the roasted product into powder and pass through a 200-mesh sieve, wash once with deionized water, and dry at 130°C to obtain the Ca 3 sc 1.9 Si 3 o 12 : 0.1Cr broadband emission phosphor material.

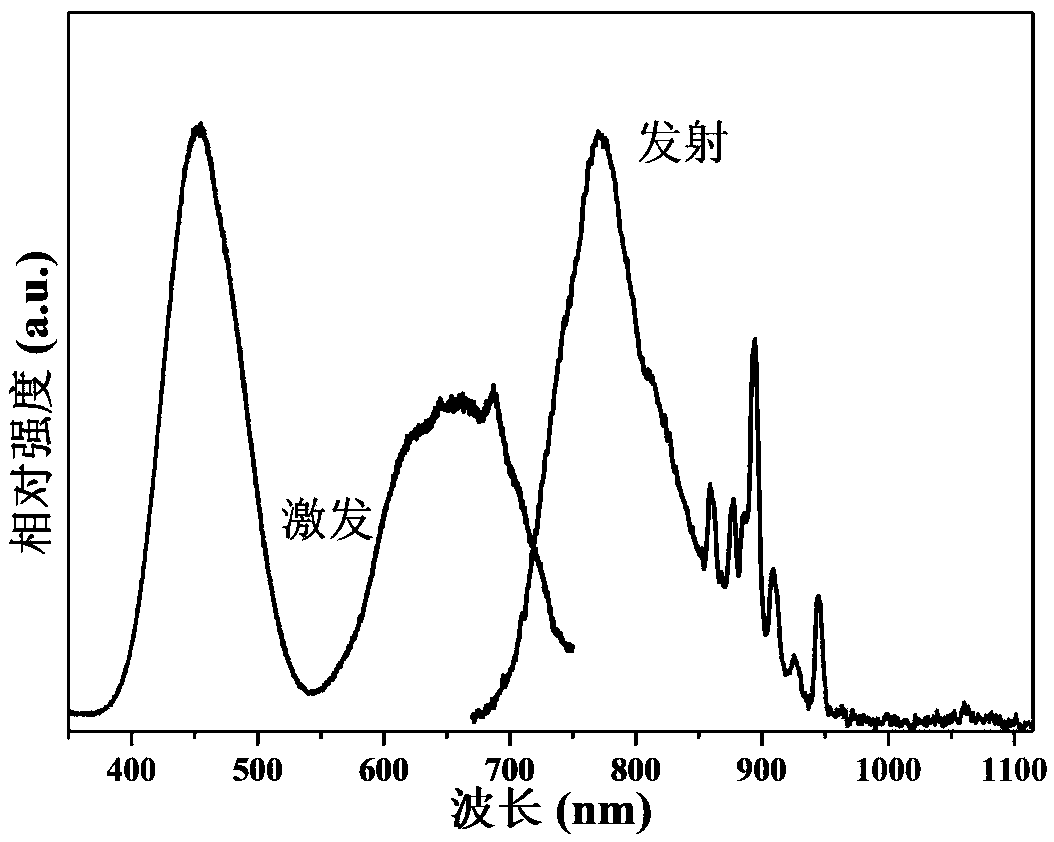

[0051] The excitation spectrum and emission spectrum of the broadband emitting phosphor material prepared in this embodiment are similar to those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com