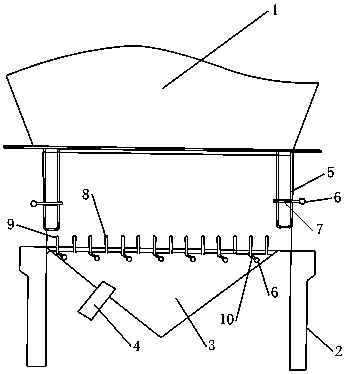

Fluidized bed roaster for treating high-copper high-lead zinc concentrates

A technology for boiling roasting furnace and zinc concentrate, which is applied in the field of roasting furnace, can solve the problems such as blockage of air caps, poor discharge, and reduced processing capacity of the boiling furnace, so as to reduce the number of maintenance, prolong the service life, and achieve a good boiling state. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Zinc concentrate contains 40~55% zinc, 1.2% lead, 1.0% copper, 6~14% iron, 28% sulfur, and 4.5% silicon dioxide. A water jacket air duct is added to each sleeve.

Embodiment 2

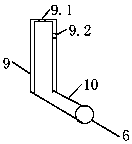

[0030] Zinc concentrate contains 40-55% of zinc, 1.8% of lead, 1.2% of copper, 6-14% of iron, 30% of sulfur and 4.5% of silicon dioxide. Add 1 to 6 rows of auxiliary air ducts, and several auxiliary air duct openings. The openings of the auxiliary air ducts are connected to the auxiliary air caps on the flower board through metal soft connections. The hole is towards the center of the fluidized furnace.

Embodiment 3

[0032] Zinc concentrate contains 40-55% of zinc, 2.2% of lead, 1.2% of copper, 6-14% of iron, 30% of sulfur and 4.5% of silicon dioxide. 1~6 rows of auxiliary air ducts are added at the position, and 1 row of auxiliary air ducts are added on both sides of the vertical direction connecting the feeding port and the discharging port. There are several auxiliary air duct openings, and the openings of the auxiliary air ducts are connected to The auxiliary air cap on the flower plate is connected, and a side hole is added to the auxiliary air cap connected to the opening of the air duct, and the opening faces the center of the fluidized fluidized furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com