Coal burning biomass steam and water coupling power generation system and process

A power generation system and biomass technology, which is applied in the field of coupled power generation technology of thermal steam and coal-fired power plants to achieve the effect of increasing the load rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

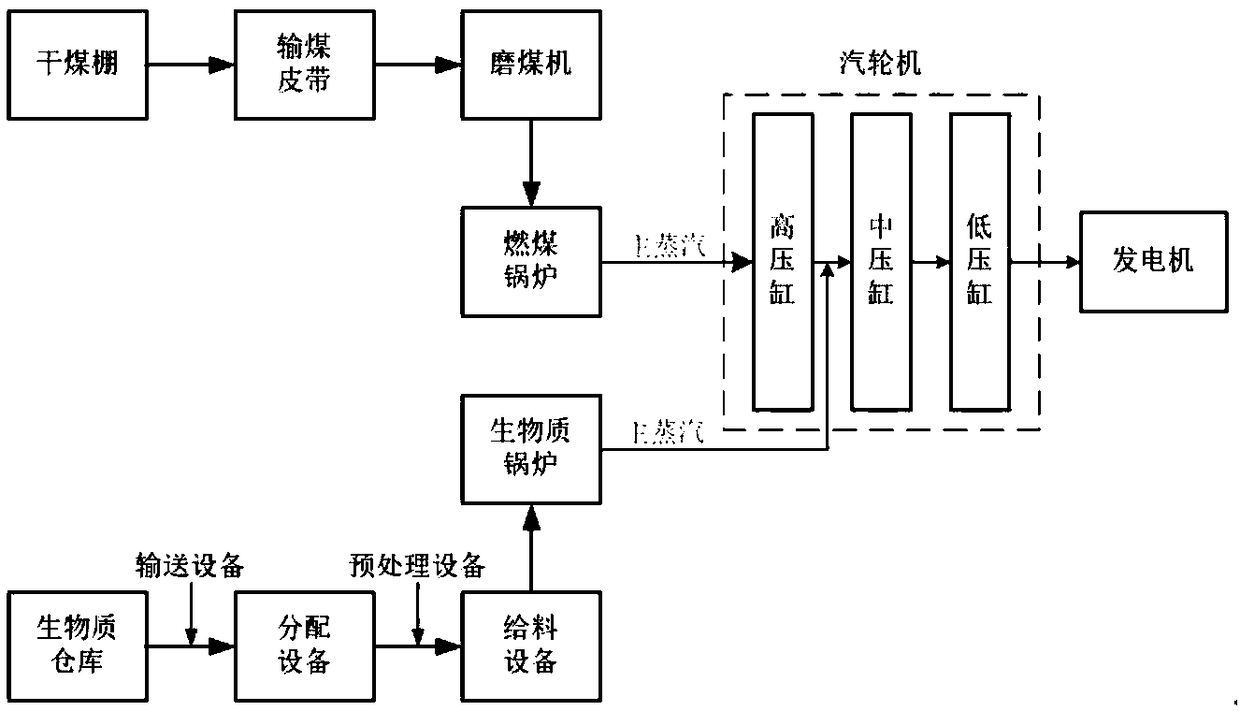

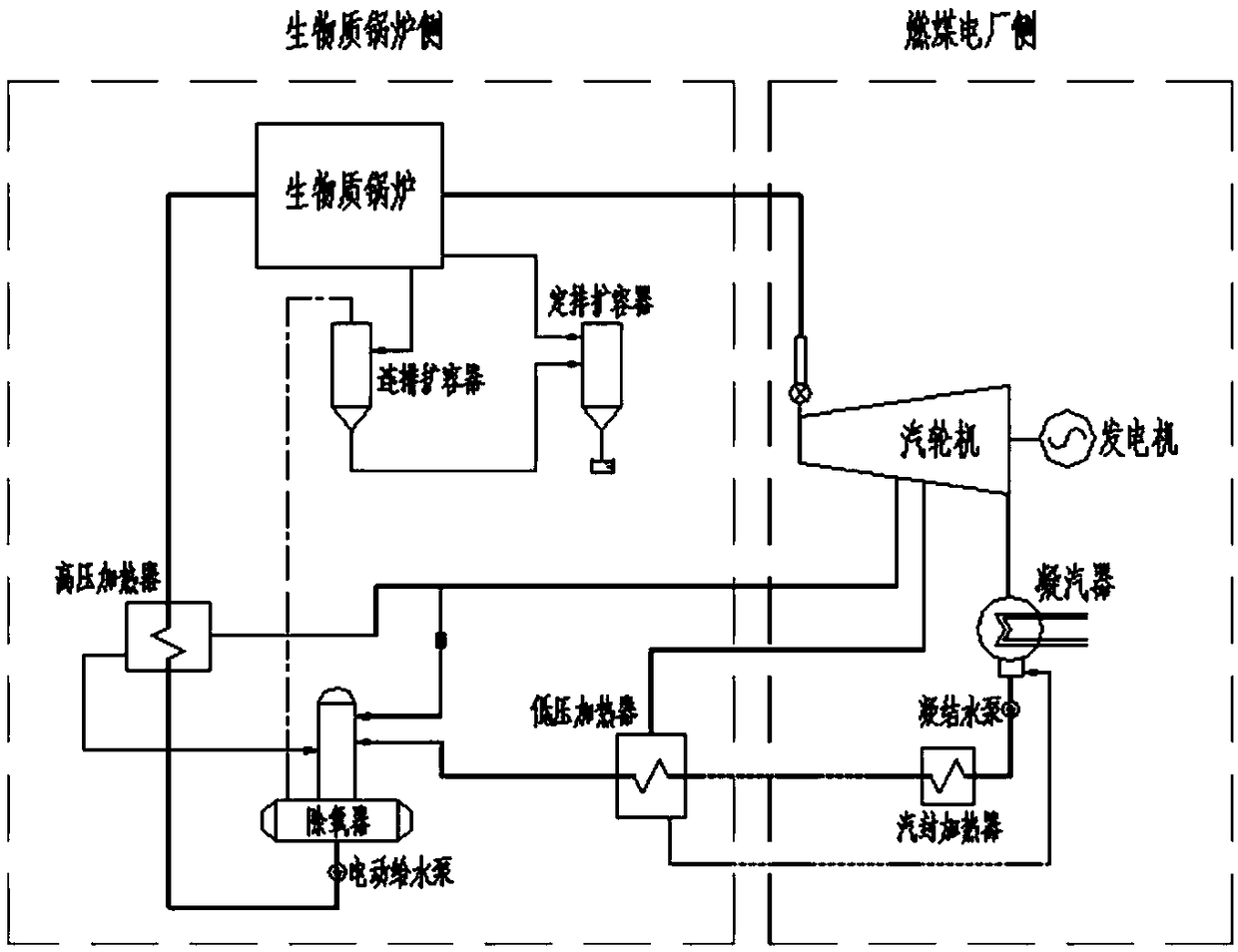

[0022] like figure 1 , 2 As shown, the present invention adds a biomass boiler on the basis of the existing coal-fired power plant equipment, supporting biomass warehouses, conveying equipment, distribution equipment, pretreatment equipment, feeding equipment, and configuration of deoxygenated water supply, heat recovery system, etc. Basic thermal system. The steam outlet of the coal-fired boiler is connected to the steam inlet of the high-pressure cylinder of the steam turbine through the steam pipeline; the steam outlet of the biomass boiler is connected to the steam inlet of the medium-pressure cylinder of the steam turbine through the steam pipeline.

[0023] A grab crane is installed in the biomass warehouse, and the grab crane grabs the biomass fuel, puts it on the conveying equipment, and conveys it to the distribution equipment through the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com