Built-in online dynamic balance device test bed for main shaft

A built-in, test bench technology, applied in the direction of static/dynamic balance test, measuring device, machine/structural component test, etc. Various requirements and other issues, to achieve the effect of reasonable layout, convenient construction, and guaranteed reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

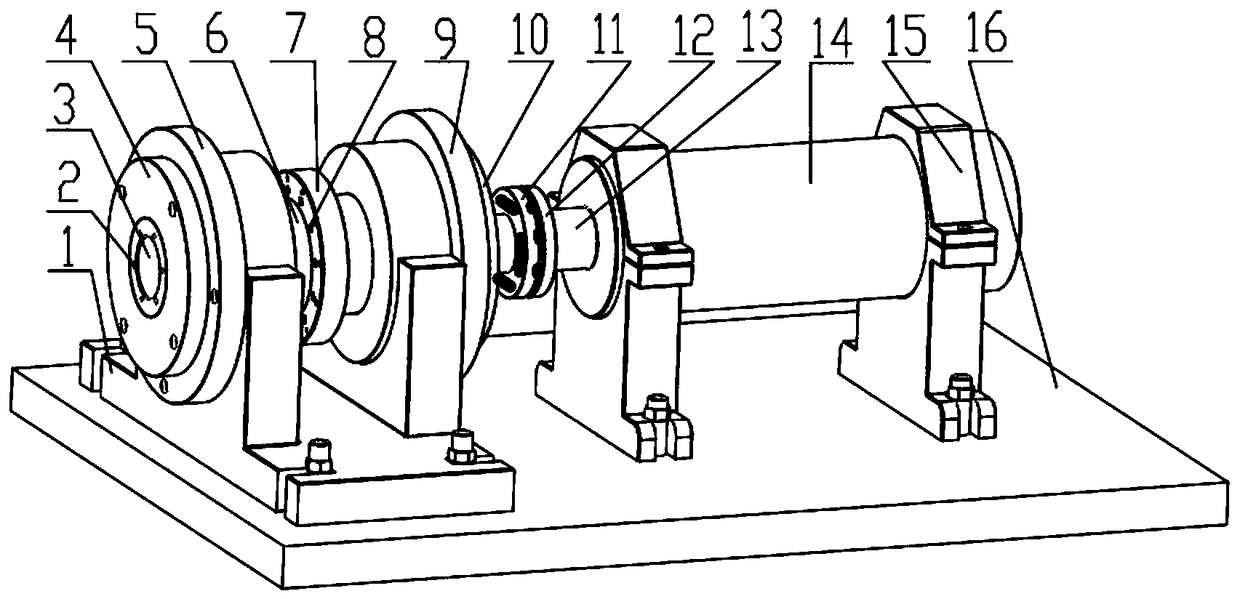

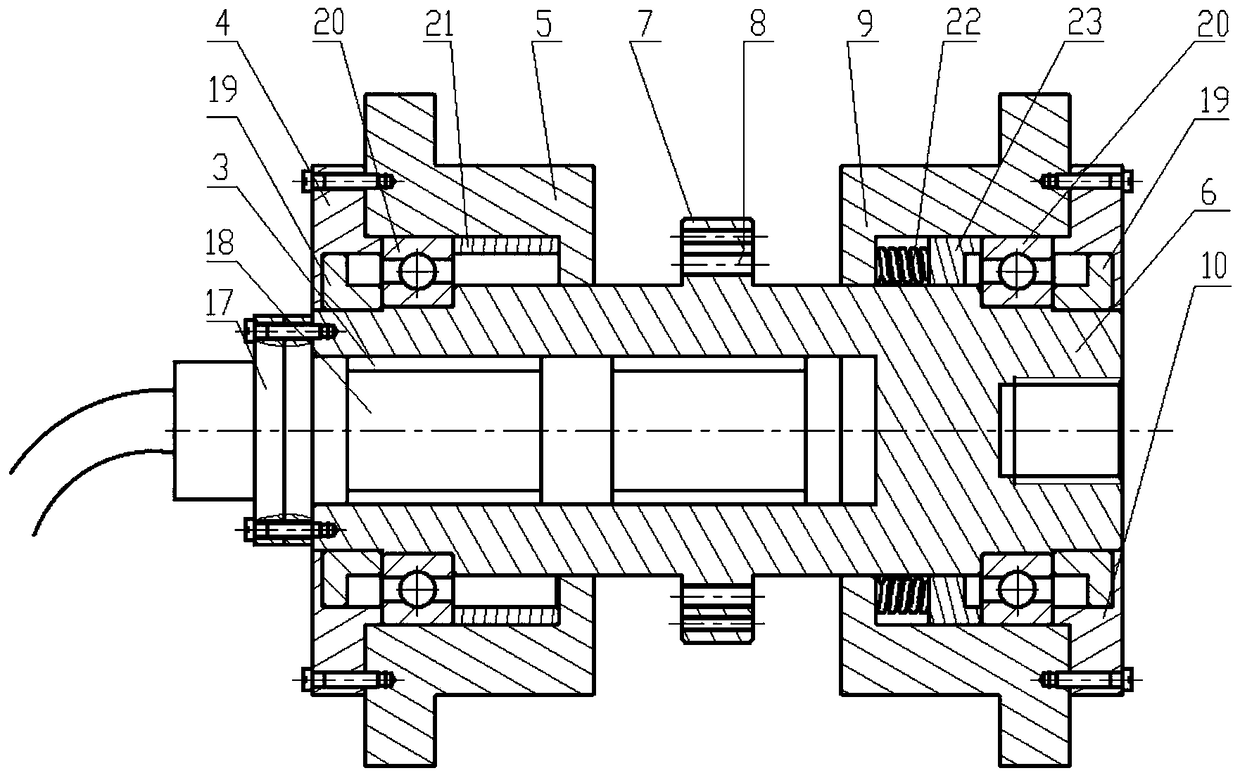

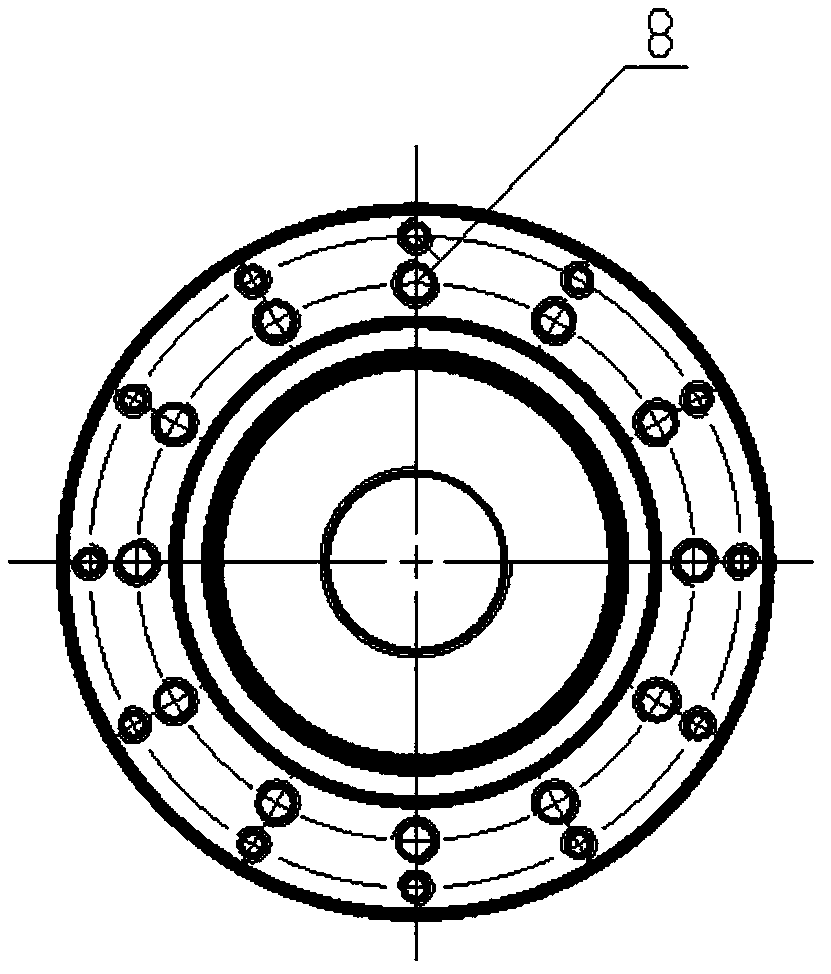

[0024] Such as figure 1 As shown, a spindle built-in online dynamic balancing device test bench includes a vibration isolation and shock absorption workbench 16. Two electric spindle bases 15 arranged front and back are connected to the vibration isolation and shock absorption workbench 16, and the electric spindle base 15 is installed There is an electric spindle 14, the front end of the electric spindle 14 is connected with a tool handle connector 13, the tool handle connector 13 is connected with the rear flange connector 12, and the rear flange connector 12 is connected with the front flange mounted on the rear end of the driven shaft 6 Part 11 realizes the transmission of motion through flexible connection, so as to achieve the purpose of driving the driven shaft 6 to rotate during the operation of the electric spindle 14; the driven shaft 6 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com