Plastic micro-irrigation belt based on leakage of porous medium and manufacturing method and equipment of plastic micro-irrigation belt

A technology of porous media and manufacturing methods, applied in botany equipment and methods, other household utensils, gardening, etc., can solve the problems of high use cost, high manufacturing cost, and low efficiency, and achieve simple manufacturing principles and high molding efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

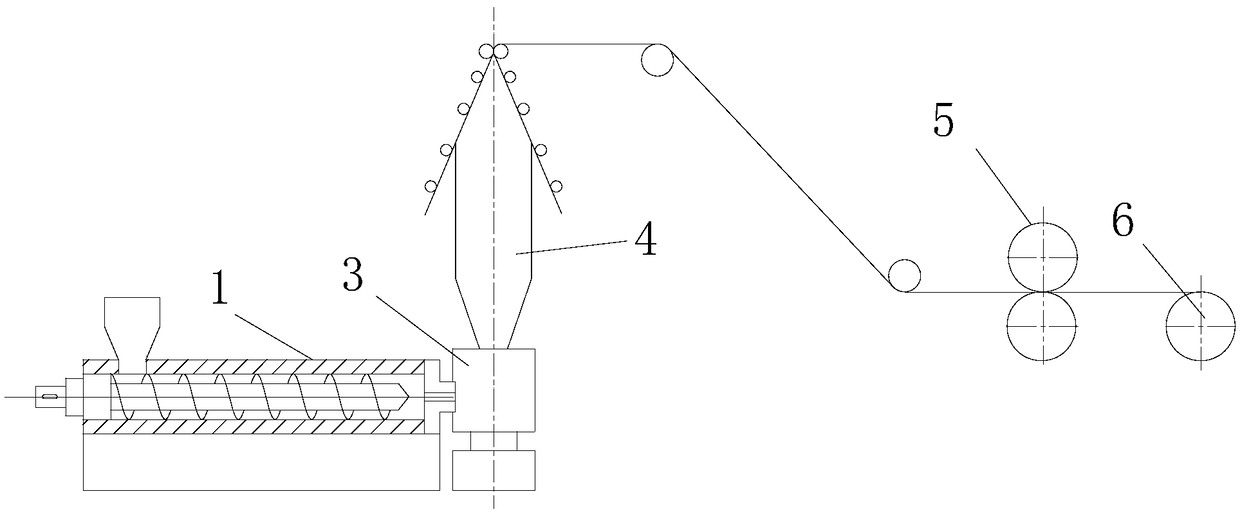

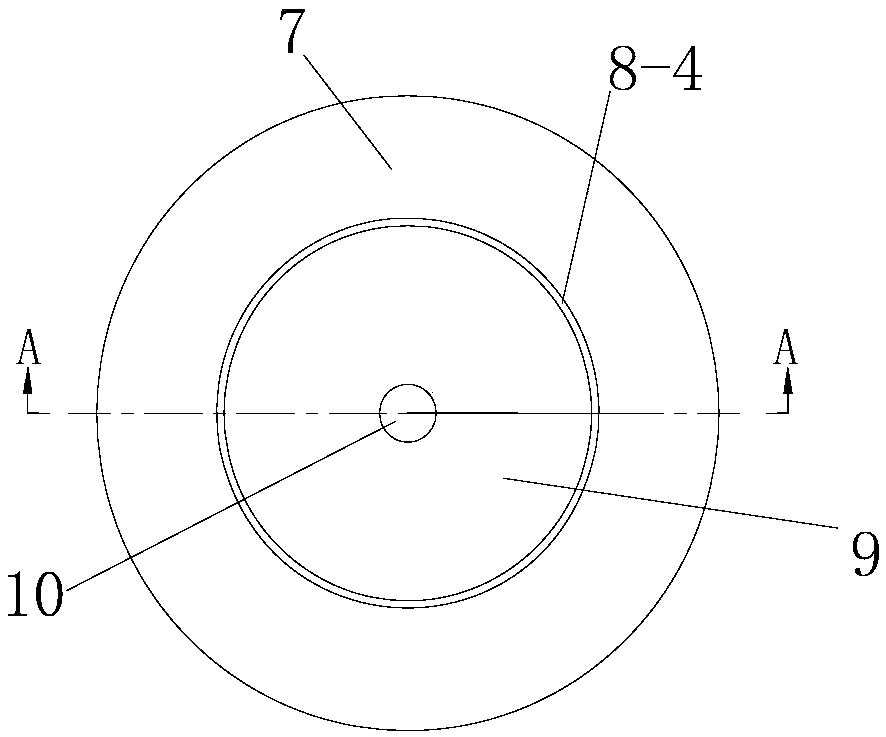

[0036] A kind of manufacturing equipment of plastic micro-irrigation tape based on porous medium seepage, such as figure 1As shown, it includes: a porogen extruder for extruding a polymer material containing a porogen, a molding die, a blow molding device (not shown in the figure), a traction device and a winding device. In this embodiment, the traction device and the winding device adopt existing devices. The forming mold includes a mandrel, a mold core and a mold sleeve. The gap between the mandrel and the mold sleeve forms a flow channel, and the center of the mandrel is provided with an air inlet channel communicated with the blow molding device. Such as figure 2 As shown, in the outlet end face of the molding die, the runner is in the shape of a ring, and the molding die in this embodiment is a general drip irrigation belt molding die.

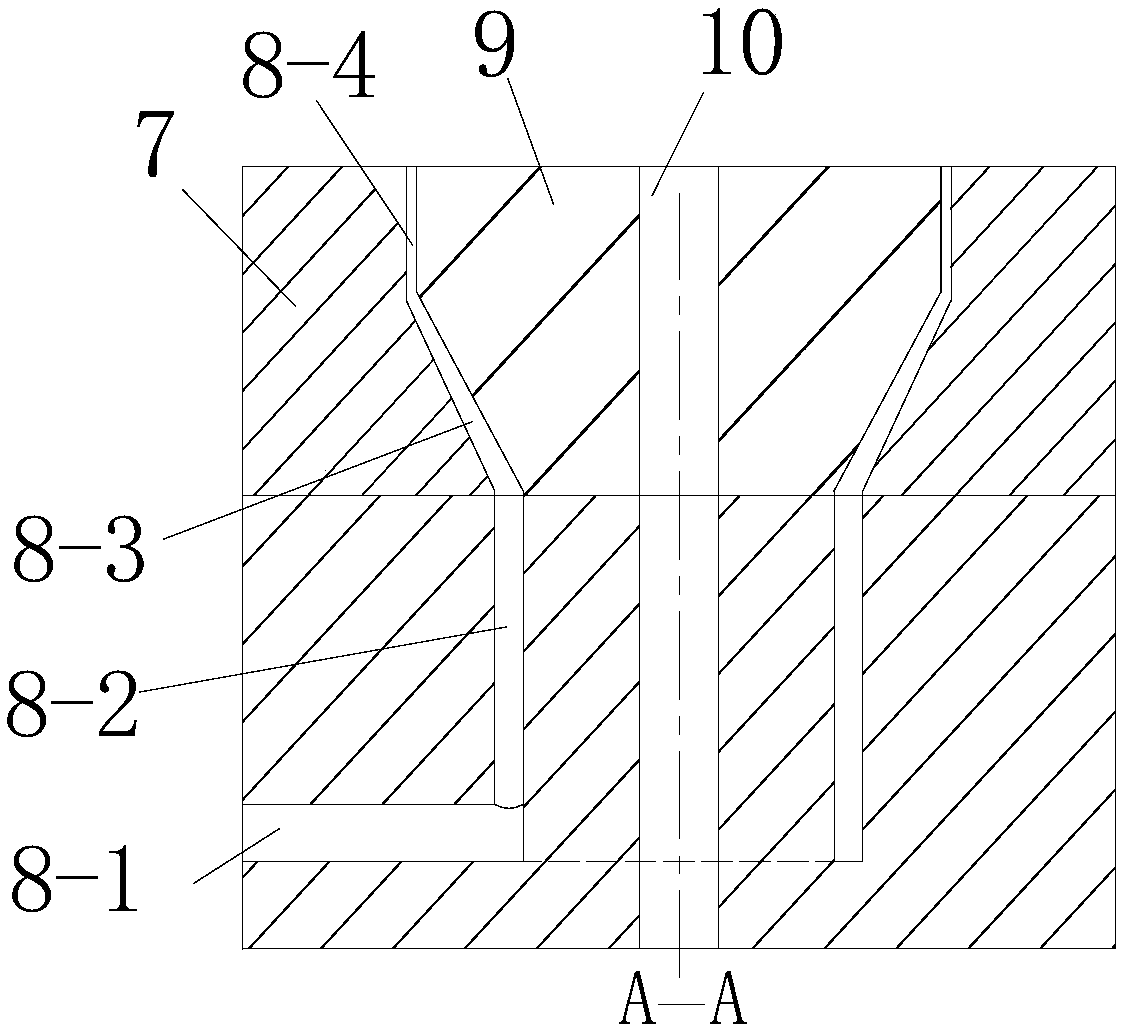

[0037] Such as image 3 As shown, the flow channel includes a feed section I, a conveying section, a diffusion section and a forming...

Embodiment 2

[0044] A kind of manufacturing equipment of plastic micro-irrigation tape based on porous medium seepage, such as Figure 5 As shown, it includes: a porogen extruder for extruding a polymer material containing a porogen, a compact extruder for extruding a polymer material without a porogen, a forming die, Blow molding device (not shown in the figure), traction device and winding device. Such as Image 6 As shown, in the outlet end face of the molding die, the runner is in the shape of a ring.

[0045] Such as Figure 7 As shown, the flow path includes a feeding section, a conveying section, a diffusing section and a forming section that are sequentially connected along the material conveying direction; wherein the feeding section includes feeding section I and feeding section II. The feeding section I and the feeding section II are both vertically connected to the lower part of the conveying section, and the feed ports of the feeding section I and the feeding section II are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com