Method for evaporating thick chromium metal layer by using single crucible

A chromium metal and crucible technology, applied in the field of semiconductor processing, can solve the problems of insufficient corrosion resistance of thin films, high preparation cost, expensive sputtering equipment, etc., and achieve the effect of easy to understand production principle and simple operation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

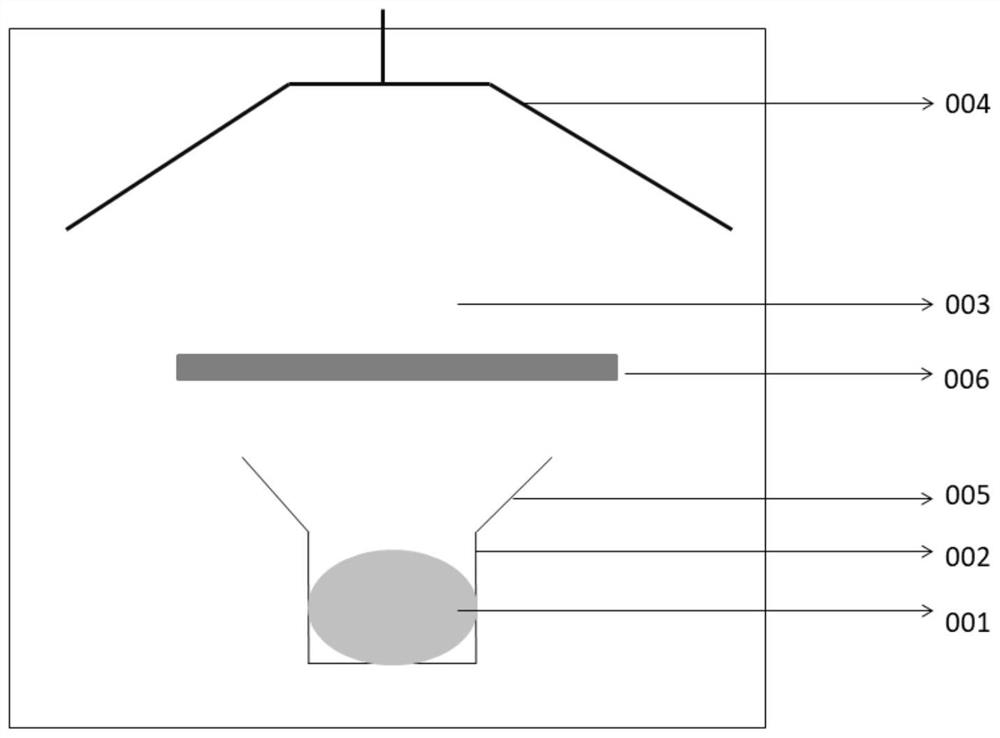

[0042] A method of evaporating thick chromium metal layers using a single crucible to make 7*8mil 2 Taking the size electrode as an example, the above-mentioned electron beam evaporation table is used, and the specific steps are as follows:

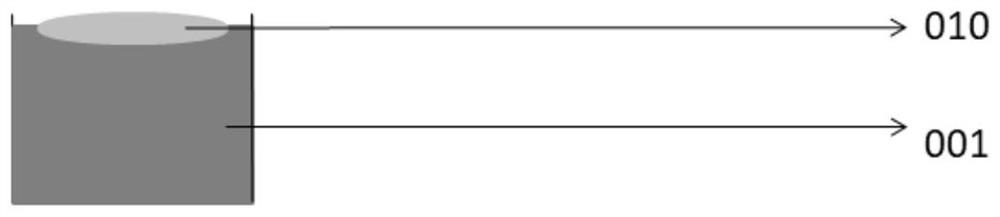

[0043] (1) Fill the crucible 007 with a capacity of 40cc with metallic chromium particles (the purity of metallic chromium is 99.99%, and the particle size is 3-5 mm) as the evaporation source 001. The upper surface of the evaporation source 001 is flush with the top of the crucible 007 ( be flush with the bottom end of the crucible side wall 005); put the wafer to be evaporated into the evaporation table cavity 003, and then evacuate to make the vacuum degree in the evaporation table cavity 003 reach more than 3.0E-6 Torr;

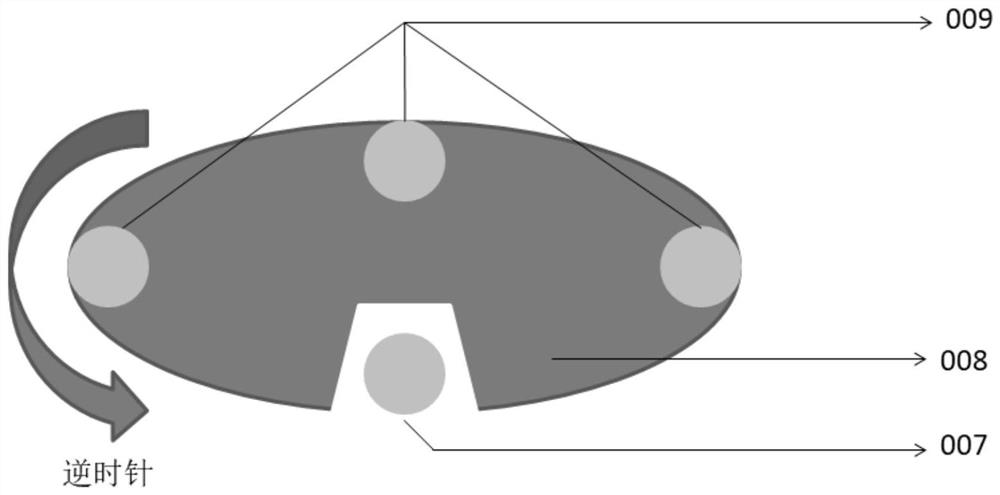

[0044] (2) the electron gun scanning is adjusted to the maximum state that the electron beam spot area is the largest, and the electron beam spot shape is adjusted to an ellipse, and the short diameter of the ellipti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com