Quick-acting rotary sand vertical flow circulating water treatment equipment

A kind of treatment equipment and water treatment technology, which is applied in the field of quick-acting sand spinning vertical flow circulating water treatment equipment, can solve the problems of loose alum flowers and slow settling speed of specific gravity, and achieve the effects of simple operation, low operating cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples are for illustrative purposes only, and are not intended to limit the scope of the present invention.

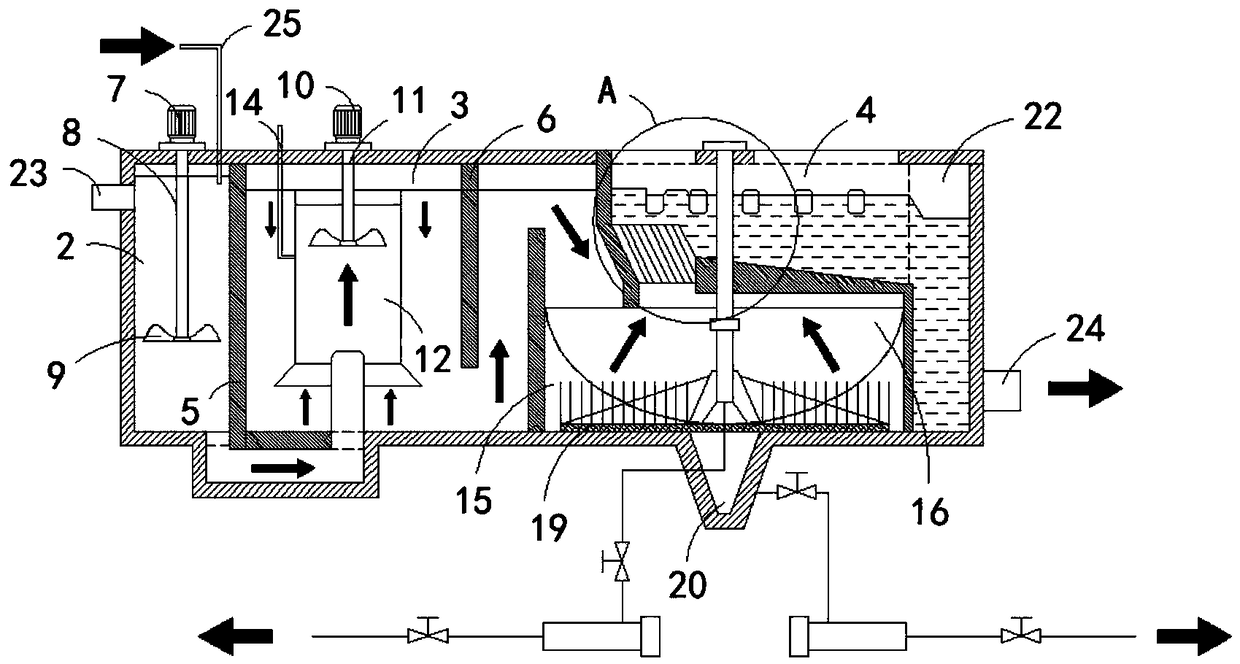

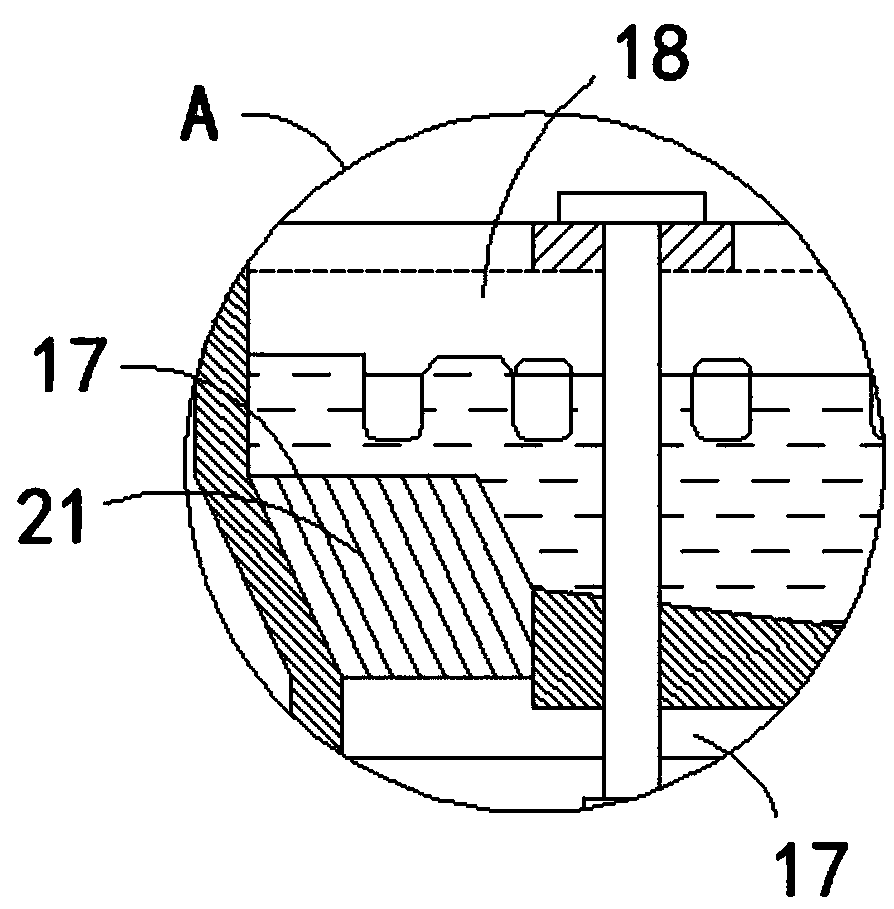

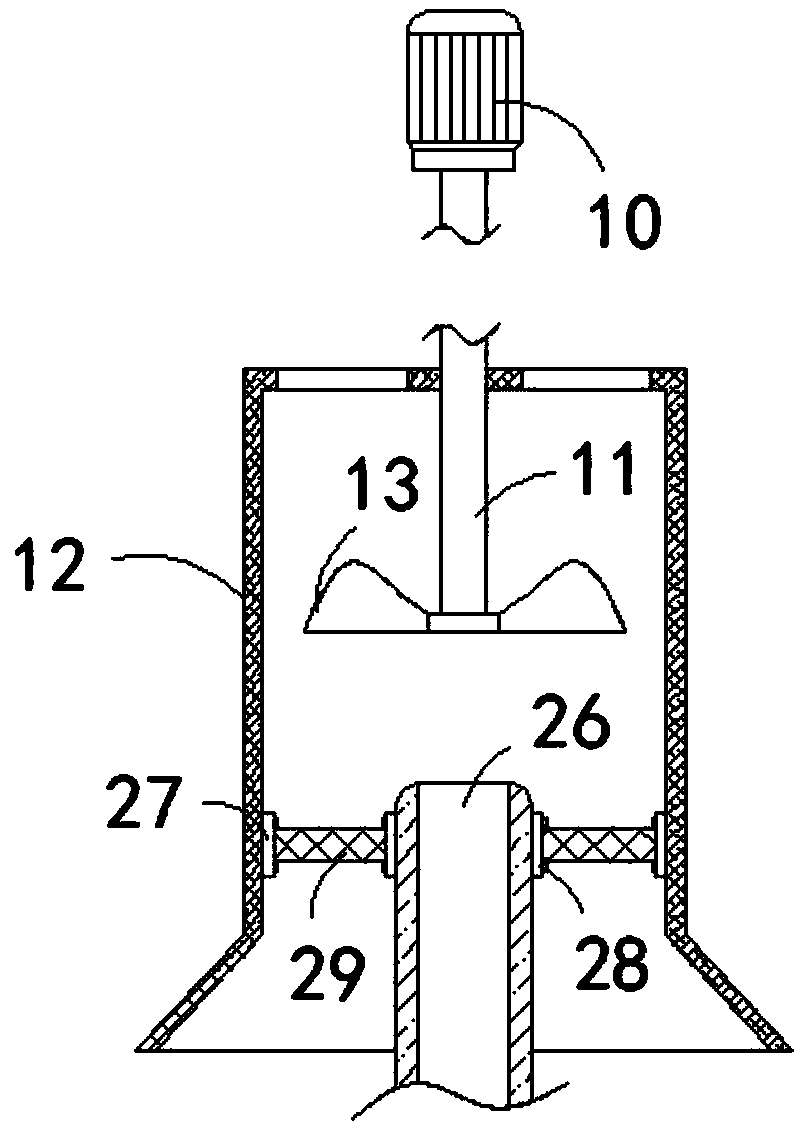

[0024] Such as Figure 1-4 As shown, a quick-acting sand rotating vertical flow circulating water treatment equipment includes a water treatment box body 1. The water treatment box body 1 is provided with a stirring zone 2, a reaction zone 3 and a sedimentation zone 4, and the stirring zone 2 and the reaction zone 3 are fixed A vertical L-shaped baffle 5 is connected, two vertical baffles 6 are fixedly connected between the reaction zone 3 and the settling zone 4, one of the baffles 6 is fixedly connected to the inner top wall of the water treatment tank 1, and Another baffle 6 is fixedly connected to the inner bottom wall of the water treatment box 1, and the top wall of the water treatment box 1 and the mixing zone 2 is fixedly connected with a first motor 7, and the output end of the first motor 7 is fixedly connected with A vertical first rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com