Photo-curing printing-based microfluid chip and manufacturing method thereof

A microfluidic chip, light curing technology, applied in the fields of biochemical equipment and methods, biochemical instruments, tissue cell/virus culture devices, etc. High-level requirements, to achieve the effect of strong customizability, flexible micro-machining process design, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

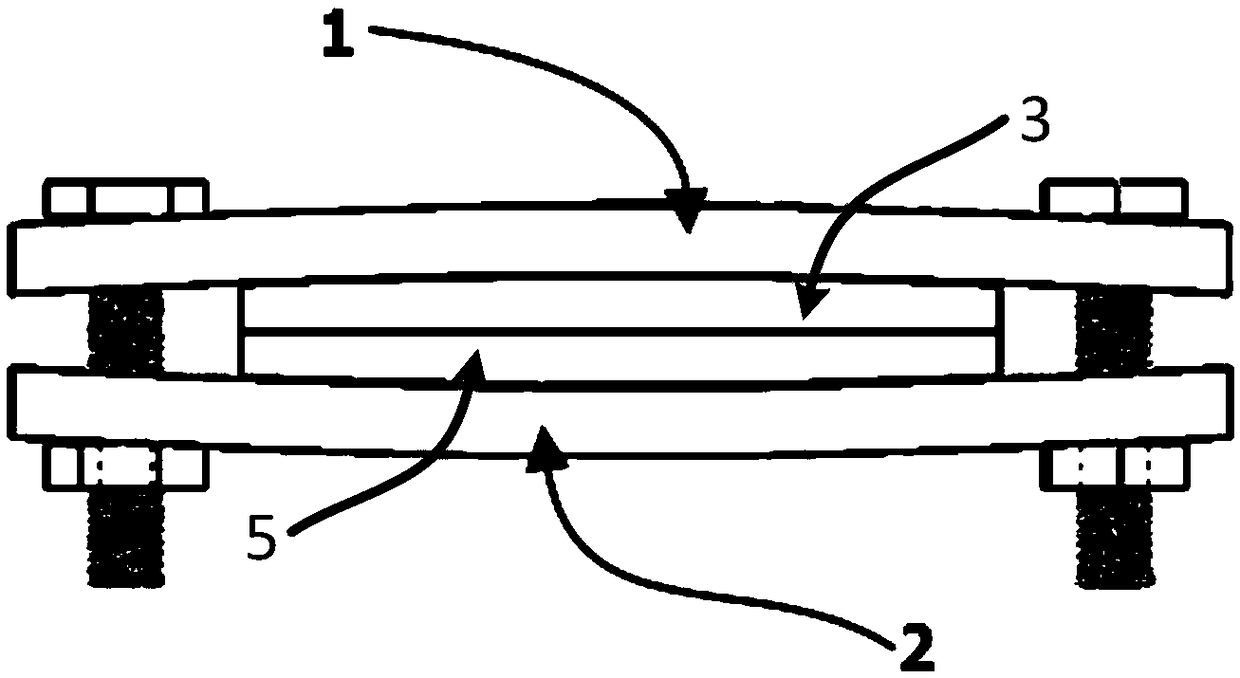

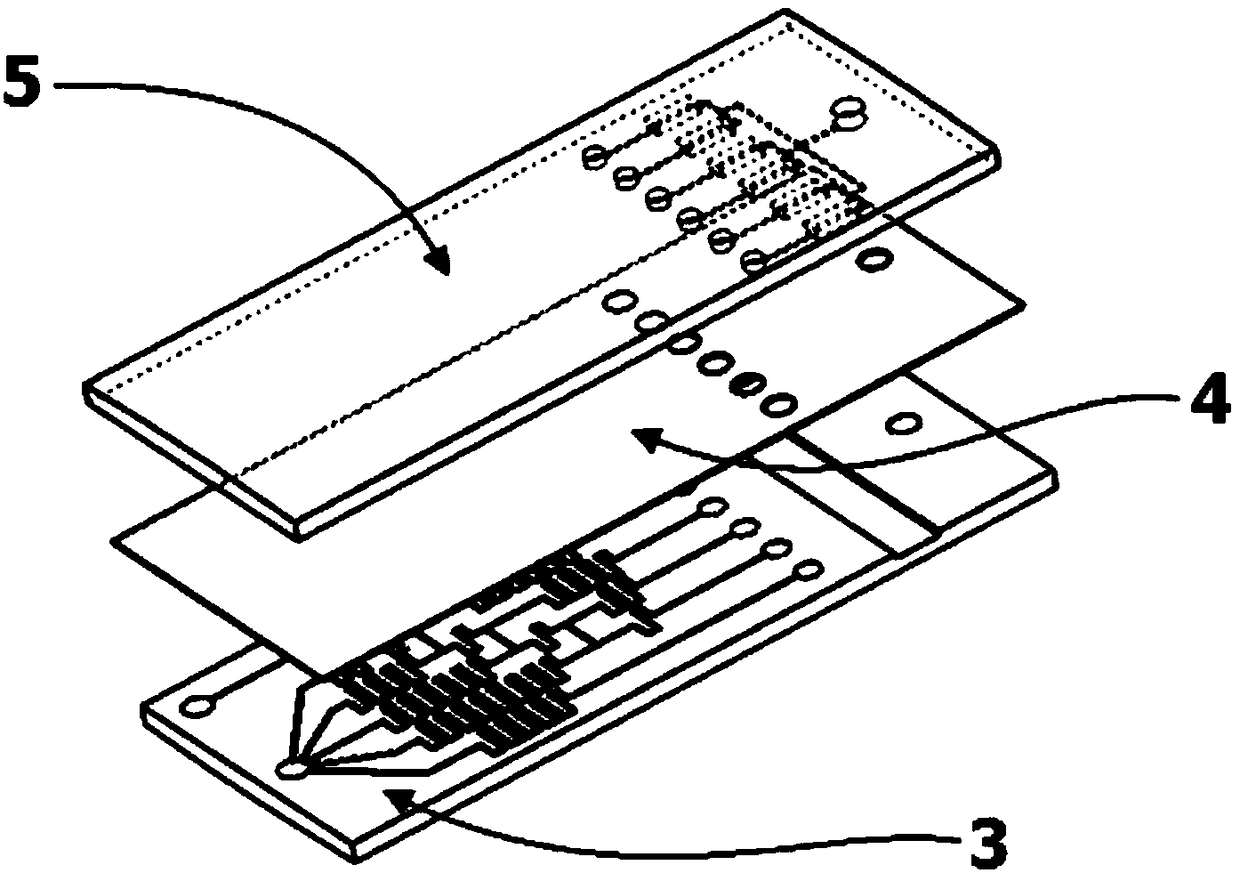

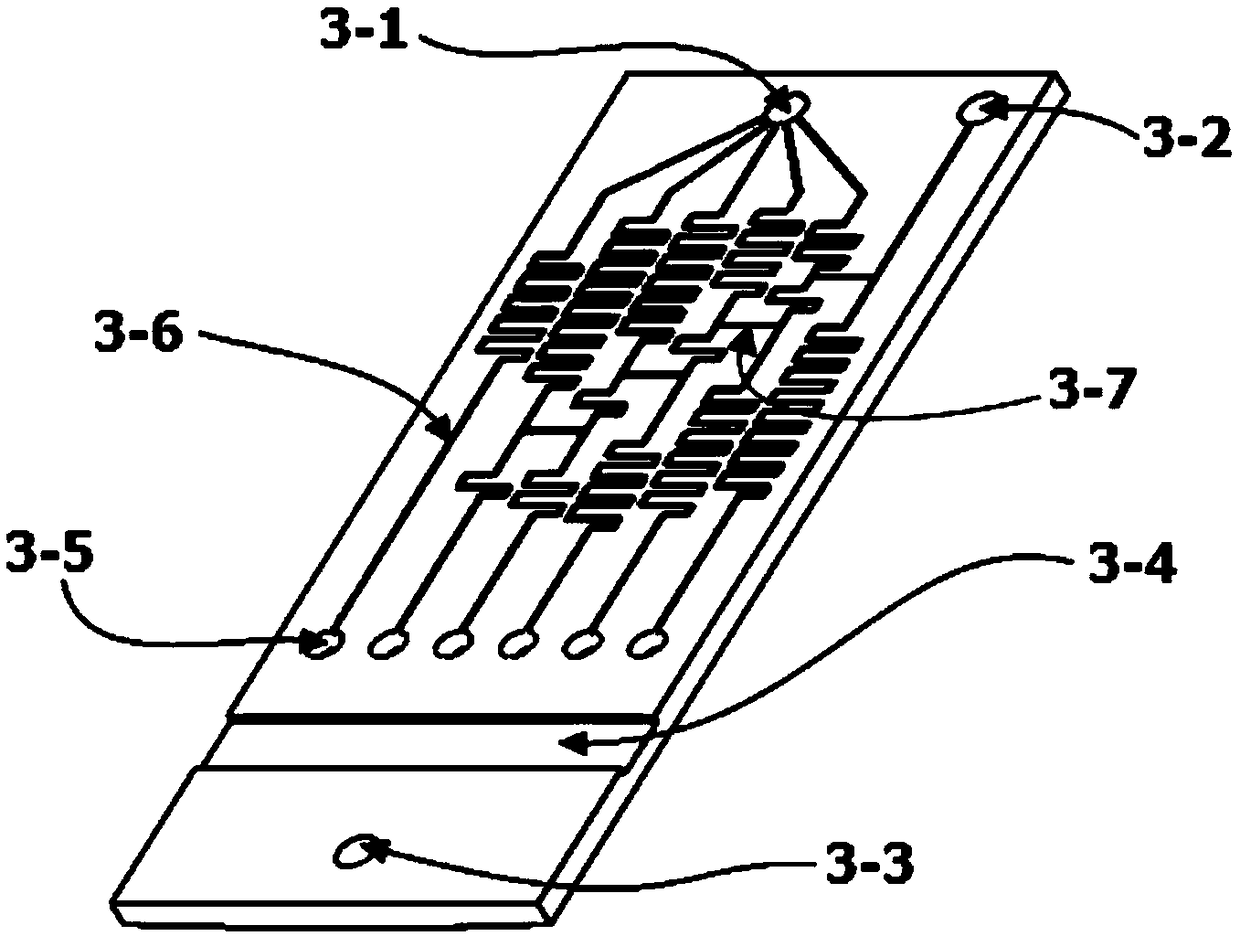

[0035] Such as figure 1 and 2 As shown, the microfluidic chip based on photocuring printing includes a top plate 1, a bottom plate 2 and a chip body. The main body of the chip is composed of a concentration gradient chip 3 , a bonding film 4 and a cell culture chip 5 stacked in sequence. The materials of the top plate 1 and the bottom plate 2 are organic glass. The concentration gradient chip 3 and the cell culture chip 5 are made of transparent photosensitive resin. The bonding film 4 is made of dimethylsiloxane (PDMS). The thickness of the bonding film 4 is 200um. The outer surfaces of the concentration gradient chip 3 and the cell culture chip 5 are both convex arc shapes. The distance between the most convex part of the outer surface of the concentration gradient chip 3 and the cell culture chip 5 and the edges on both sides along the thickness direction of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com