Photovoltaic module structure capable of reducing potential cause attenuation effect of photovoltaic module

A photovoltaic module and attenuation effect technology, applied in the field of photovoltaic module structure, can solve problems such as affecting the power generation efficiency of photovoltaic modules and the failure of solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

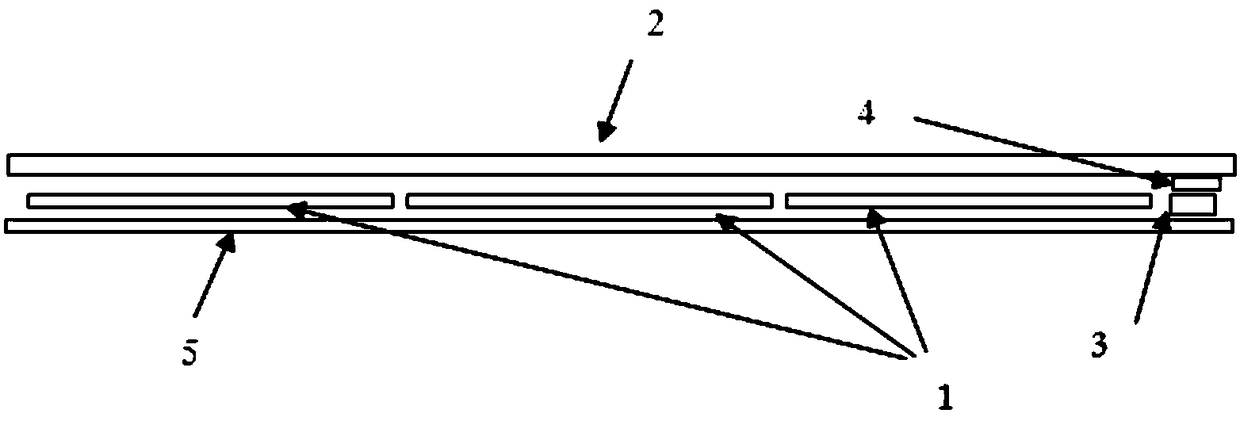

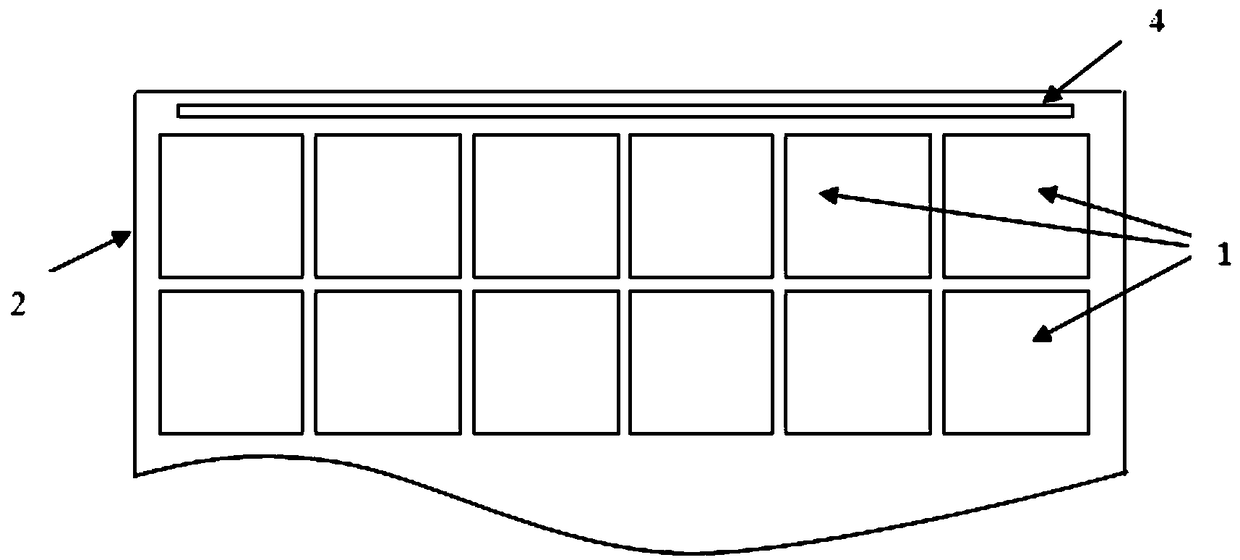

[0025] Example 1: Combining figure 1 , a double-glass module structure that reduces the potential attenuation effect of photovoltaic modules, the upper packaging glass 2, the conductive strip 4, the bus strip 3, the conductive strip 4, and the back plate 5 are sequentially stacked and contacted, and the back plate 5 is the lower packaging glass. The function of the conductive strip 4 is to be closely attached to the upper packaging glass 2 / back plate 5, and has a good adhesion with the glass 2 / back plate 5, and will not cause the conductive strip 4 to contact the upper packaging glass 2 / back plate after a long time. The backplane 5 is delaminated. Silver plating and copper plating are used to attach the conductive strip 4 to the upper packaging glass 2. The position where the conductive strip 4 is attached cannot block the light-receiving surface of the cell 1. The bus strip 3 is a tin-plated copper strip that can be connected to the conductive strip. 4 Well soldered and turn...

Embodiment 2

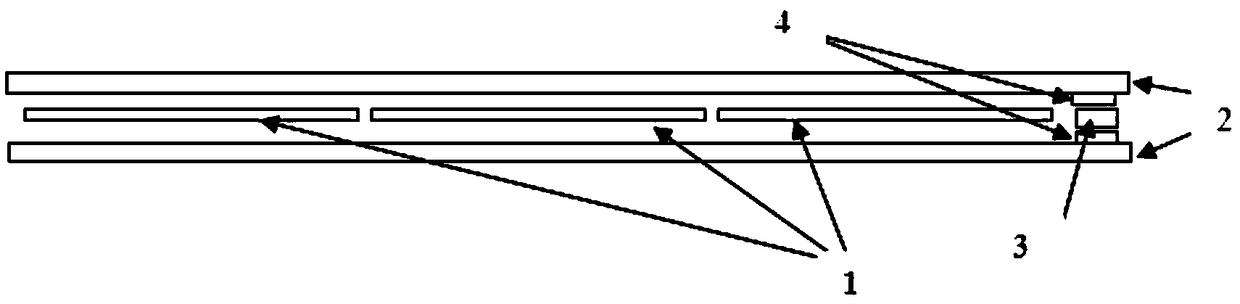

[0026] Example 2: Combining figure 2 , a single-glass module structure that reduces the attenuation effect of potential incentives for photovoltaic modules. The upper packaging glass 2, conductive strips 4, bus strips 3, and backplane 5 are sequentially stacked and contacted, and the backplane 5 is an organic backplane. The function of the conductive strip 4 is that it can be closely attached to the upper packaging glass 2, and has good adhesion with the glass 2, and will not cause delamination of the conductive strip 4 and the upper packaging glass 2 after a long time. Silver plating and copper plating are used to attach the conductive strip 4 to the upper packaging glass 2. The position where the conductive strip 4 is attached cannot block the light-receiving surface of the battery sheet 1. The bus strip 3 is a tin-plated copper strip that can be connected to the conductive strip. 4 Well soldered and turned on.

[0027] In Embodiment 1 and Embodiment 2, the photovoltaic mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com