High-power microwave mode-conversion antenna based on diffraction period structure

A high-power microwave, periodic structure technology, applied in the direction of radiating element structure, individually energized antenna arrays, antenna combinations with different interactions, etc., can solve problems such as limited application range, large axis angle, dielectric loss, etc. Achieving the effects of wide application fields, improved power capacity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better illustrate the purpose, advantages and technical solutions of the present invention, the present invention will be further elaborated below in conjunction with specific examples. It should be noted that the specific implementation examples given below are only for the purpose of explaining and illustrating the present invention in detail, and are not intended to limit the present invention.

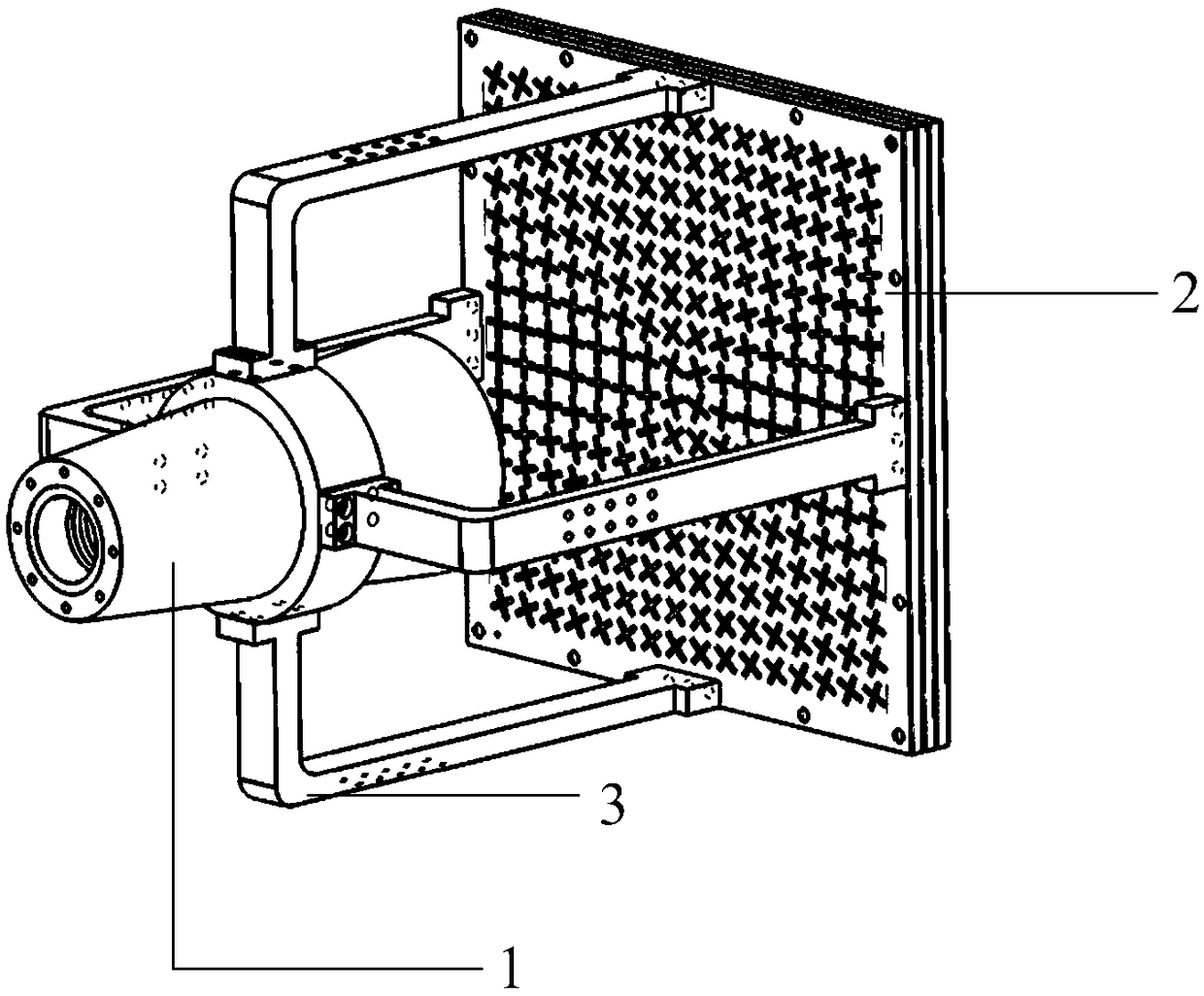

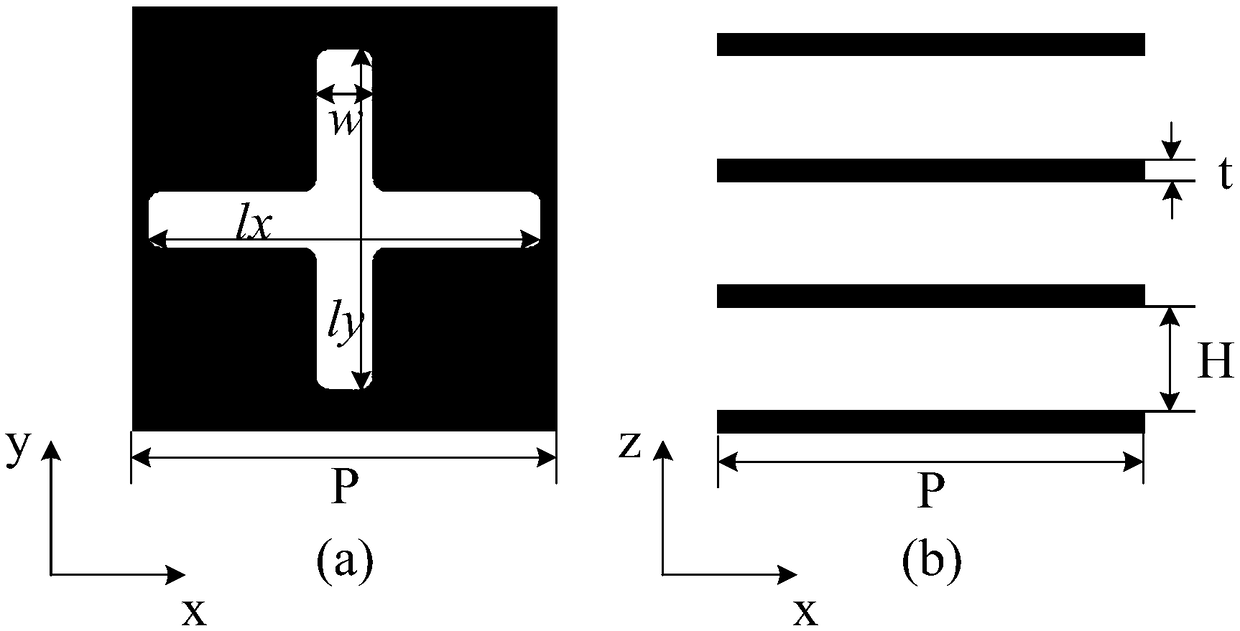

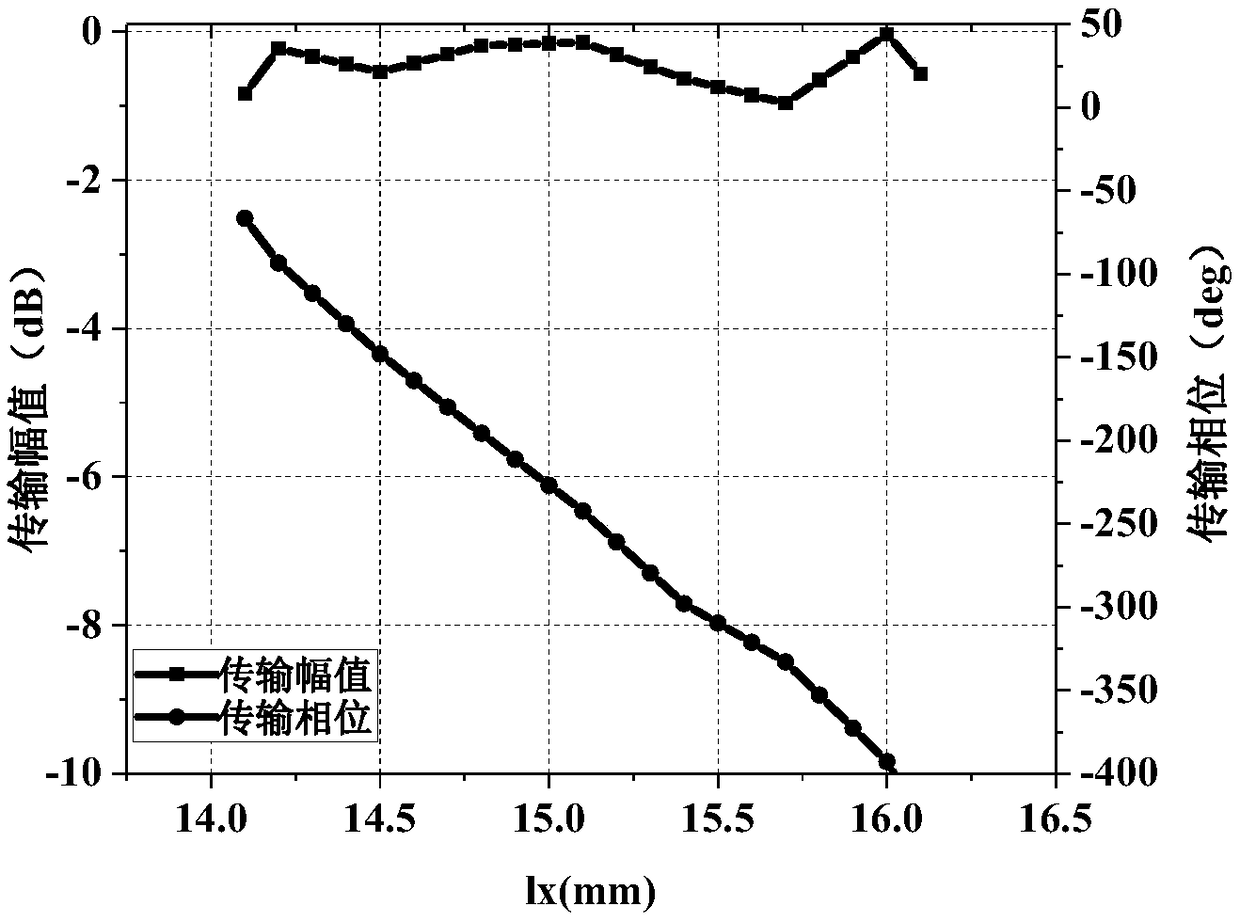

[0028] This embodiment is a kind of TM 01 A high-power microwave mode-to-mode antenna based on a diffraction periodic structure that converts the mode into a single linear polarization mode. The overall structure is shown in figure 1 As shown, the antenna is composed of a primary feed 1, an antenna array 2 and a support 3, and the primary feed is TM 01 The mode exciter, with an exciter diameter of 80mm, is set directly above the antenna front 2 through the bracket 3, and feeds the antenna front in a feed-forward manner. The antenna front is composed of 256 tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com