Method for making double-sided wire-buried printed circuit board by using imageable dielectric material

A technology for printed circuit boards and dielectric materials, applied in the directions of printed circuits, printed circuit manufacturing, multilayer circuit manufacturing, etc., can solve problems such as poor alignment of buried layers, open circuits, etc. Positioning system system, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] see Figure 1 to Figure 9 , the method for making a double-sided embedding printed circuit board made of an imageable dielectric material according to the present invention, which comprises the following steps:

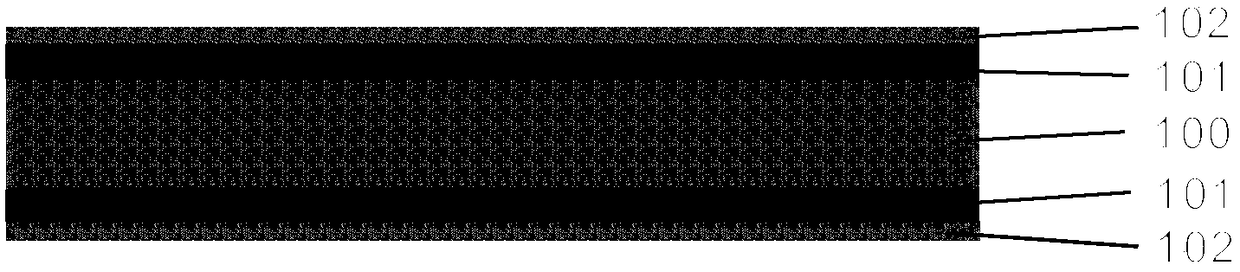

[0037] a) First provide a core board 100 with a detachable structure, 101 is a detachable carrier copper foil, and 102 is an auxiliary copper foil for forming the first circuit pattern, such as figure 1 shown;

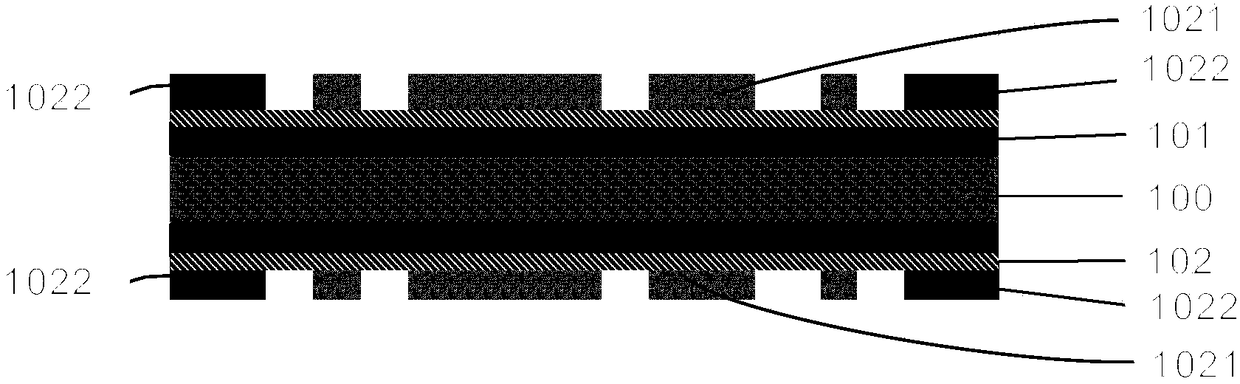

[0038] b) On the surface of the auxiliary copper foil 102, the first circuit pattern 1021 of the printed board is made by pattern transfer and pattern electroplating, and the positioning reference pattern 1022 is made at the same time, such as figure 2 shown;

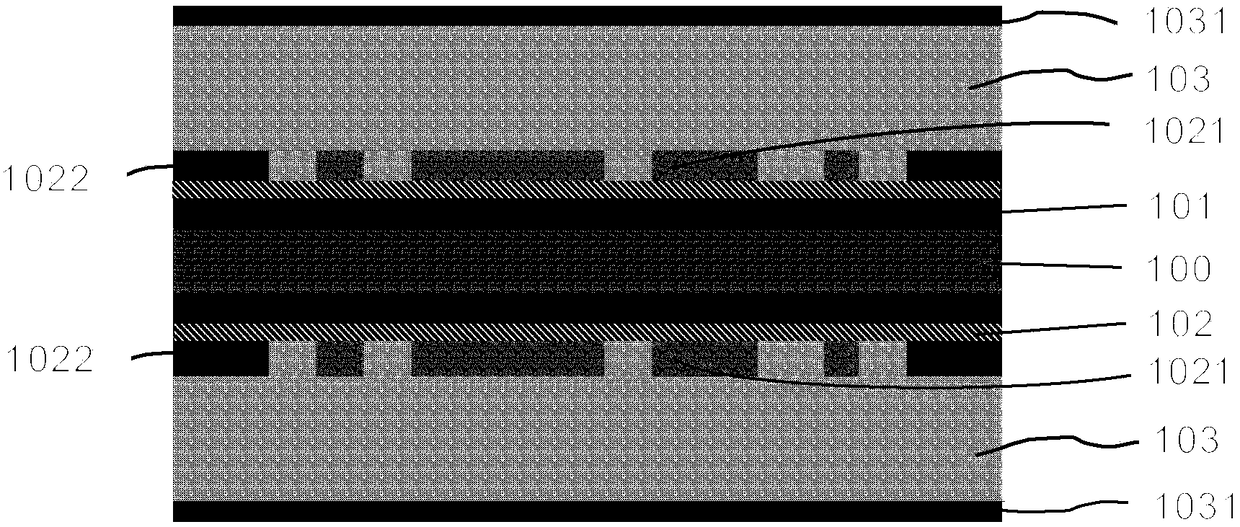

[0039] c) On the first circuit pattern 1021, an imageable dielectric material 103 is pressed to form a first embedded circuit, 1021 is the first embedded circuit, and 1031 is an imageable dielectric material protective layer, such as image 3 shown;

[0040] d) Use the positioning reference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com