Agastache rugosus juice and preparation method thereof

A technology of Huoxiang juice and Huxiang, which is applied in the direction of food science, can solve the problems of residual chemical components, easy browning of color and easy loss of flavor, and achieve the effect of no residue of harmful substances, bright color and mellow taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] Embodiments of the present invention also provide a preparation method of Huoxiang juice, comprising the following steps:

[0022] S1, pretreatment;

[0023] The dry patchouli and water are uniformly mixed in a ratio of 1:8-12, and the water used is sterile water, thereby ensuring that the prepared patchouli juice has less harmful bacteria content, thereby ensuring the safety of the patchouli juice.

[0024] The mixing temperature of the dry patchouli and water is 90-100° C., and the mixing time is 30-40 minutes. Mixing under the above conditions can ensure the full expansion of the dry patchouli and facilitate the dissolution of active ingredients in the dry patchouli.

[0025] Then crush the dry patchouli and water mixture. Firstly mix the dried ageratum and water and then crush the wall, which can prevent the light dry ageratum from flying around, ensure that there is enough dried ageratum and water for mixing and pressing, and ensure the subsequent pressing effect,...

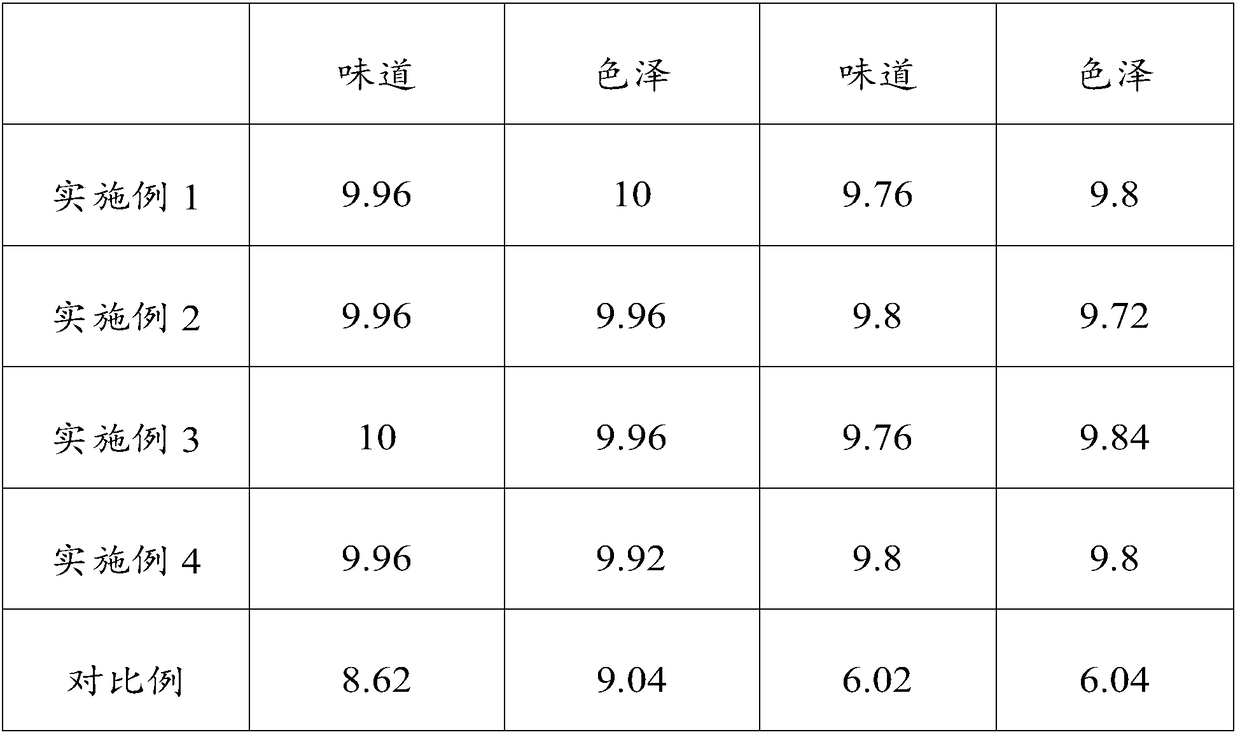

Embodiment 1

[0035] The Huoxiang juice provided in this embodiment includes 25Kg chicken extract, 2Kg yeast extract, 7Kg flavoring agent, 1Kg modified starch and 4Kg Huoxiang liquid. Wherein, 7Kg flavoring agent comprises 4Kg sodium salt, 1Kg sucrose and 2Kg monosodium glutamate.

[0036] The preparation method of the Huoxiang juice provided by the present embodiment may further comprise the steps:

[0037] S1, pretreatment;

[0038] Mix the dry patchouli and water evenly in a ratio of 1:8, wherein the mixing temperature of the dry patchouli and water is 90° C., and the mixing time is 30 minutes. Then crush the mixture and press it, then let it stand for 1 hour, and finally separate the solid and liquid.

[0039] 1Kg of modified starch and 15Kg of water are mixed to obtain starch slurry.

[0040] S2, prepare Huoxiang juice;

[0041] Add chicken extract, yeast extract, carbohydrates, monosodium glutamate, sodium salt, modified starch, and Huoxiang liquid into the reaction kettle and mix...

Embodiment 2

[0043]The Huoxiang juice provided in this embodiment includes 40Kg chicken extract, 6Kg yeast extract, 23Kg flavoring agent, 3Kg modified starch and 12Kg Huoxiang liquid. Among them, 23Kg flavoring agent includes 10Kg sodium salt, 5Kg sucrose and 8Kg monosodium glutamate.

[0044] The preparation method of the Huoxiang juice provided by the present embodiment may further comprise the steps:

[0045] S1, pretreatment;

[0046] Mix the dry patchouli and water evenly in a ratio of 1:12, wherein the mixing temperature of the dry patchouli and water is 100° C., and the mixing time is 40 minutes. Then pulverize the above mixture and press it, then let it stand for 1.5 hours, and finally separate the solid and liquid.

[0047] 3Kg of modified starch and 20Kg of water are mixed to obtain starch slurry.

[0048] S2, prepare Huoxiang juice;

[0049] Add chicken extract, yeast extract, carbohydrates, monosodium glutamate, sodium salt, modified starch and Huoxiang liquid into the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com