Method for preparing nano zinc oxide aerogel

A nano-zinc oxide and airgel technology, applied in the field of airgel, can solve the problems of poor porosity and adsorption performance, poor airgel structural strength, etc., to achieve improved adsorption effect, low production cost, and improved dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

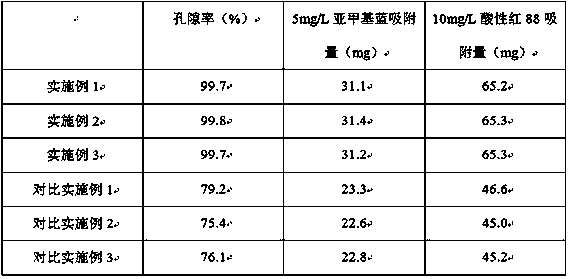

Examples

Embodiment 1

[0018] A method for preparing airgel containing nano-zinc oxide, is characterized in that, comprises the following steps:

[0019] (1) After mixing 50 parts by weight of saturated ammonia solution and zinc sulfate solution with a concentration of 0.5 mol / L at a volume ratio of 3:1, stir at 500 rpm for 10 minutes, and then raise the temperature of the mixture to 65 °C, sonicate for 10 minutes to obtain nano-zinc oxide precursor dispersion;

[0020] (2) modifying the nano-zinc oxide precursor dispersion obtained in step (1) to obtain a modified nano-zinc oxide precursor;

[0021] (3) Dissolve 10 parts of ethyl orthosilicate in distilled water to make a solution of ethyl orthosilicate with a concentration of 0.5mol / L, then slowly add 3 parts of oxalic acid solution of 0.6mol / L dropwise, at 35°C, Sonicate for 2 hours, then adjust the pH value to 6, stir at 700rpm for 20 minutes, add the product from step (2), and continue to disperse for 10 minutes to obtain a mixed dispersion; ...

Embodiment 2

[0027] A method for preparing airgel containing nano-zinc oxide, is characterized in that, comprises the following steps:

[0028] (1) After mixing 70% saturated ammonia solution in parts by weight and zinc sulfate solution with a concentration of 0.7mol / L at a volume ratio of 4:1, stir at 550rpm for 12min, and then raise the temperature of the mixture to 70°C °C, sonicate for 11 minutes to obtain nano-zinc oxide precursor dispersion;

[0029] (2) modifying the nano-zinc oxide precursor dispersion obtained in step (1) to obtain a modified nano-zinc oxide precursor;

[0030] (3) Dissolve 14 parts of ethyl orthosilicate in distilled water to make a solution of ethyl orthosilicate with a concentration of 0.8mol / L, then slowly add 4 parts of oxalic acid solution of 0.7mol / L dropwise, at 40°C, Ultrasonic treatment for 3 hours, then adjust the pH value to 7, stir at 750rpm for 22 minutes, add the result of step (2), and continue to disperse for 12 minutes to obtain a mixed dispersi...

Embodiment 3

[0036] A method for preparing airgel containing nano-zinc oxide, is characterized in that, comprises the following steps:

[0037] (1) Mix 100% saturated ammonia solution in parts by weight and zinc sulfate solution with a concentration of 1mol / L at a volume ratio of 4:1, stir at 600rpm for 15min, and then raise the temperature of the mixture to 75°C , sonicated for 12 minutes to obtain nano zinc oxide precursor dispersion;

[0038] (2) modifying the nano-zinc oxide precursor dispersion obtained in step (1) to obtain a modified nano-zinc oxide precursor;

[0039] (3) Dissolve 20 parts of ethyl orthosilicate in distilled water to make a solution of ethyl orthosilicate with a concentration of 1mol / L, then slowly add 5 parts of 0.8mol / L oxalic acid solution dropwise, at 45°C, ultrasonically Treat for 3 hours, then adjust the pH value to 7, stir at 800 rpm for 25 minutes, then add the product from step (2), and continue to disperse for 15 minutes to obtain a mixed dispersion;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com