Preparation method for controlling particle size of silver phosphate crystals by using carbon nanotubes

A technology of carbon nanotubes and crystal particle size, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems that hinder the popularization and application of Ag, irregular shape, large particle size, etc. Achieve excellent visible light catalytic performance, simple preparation method, simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

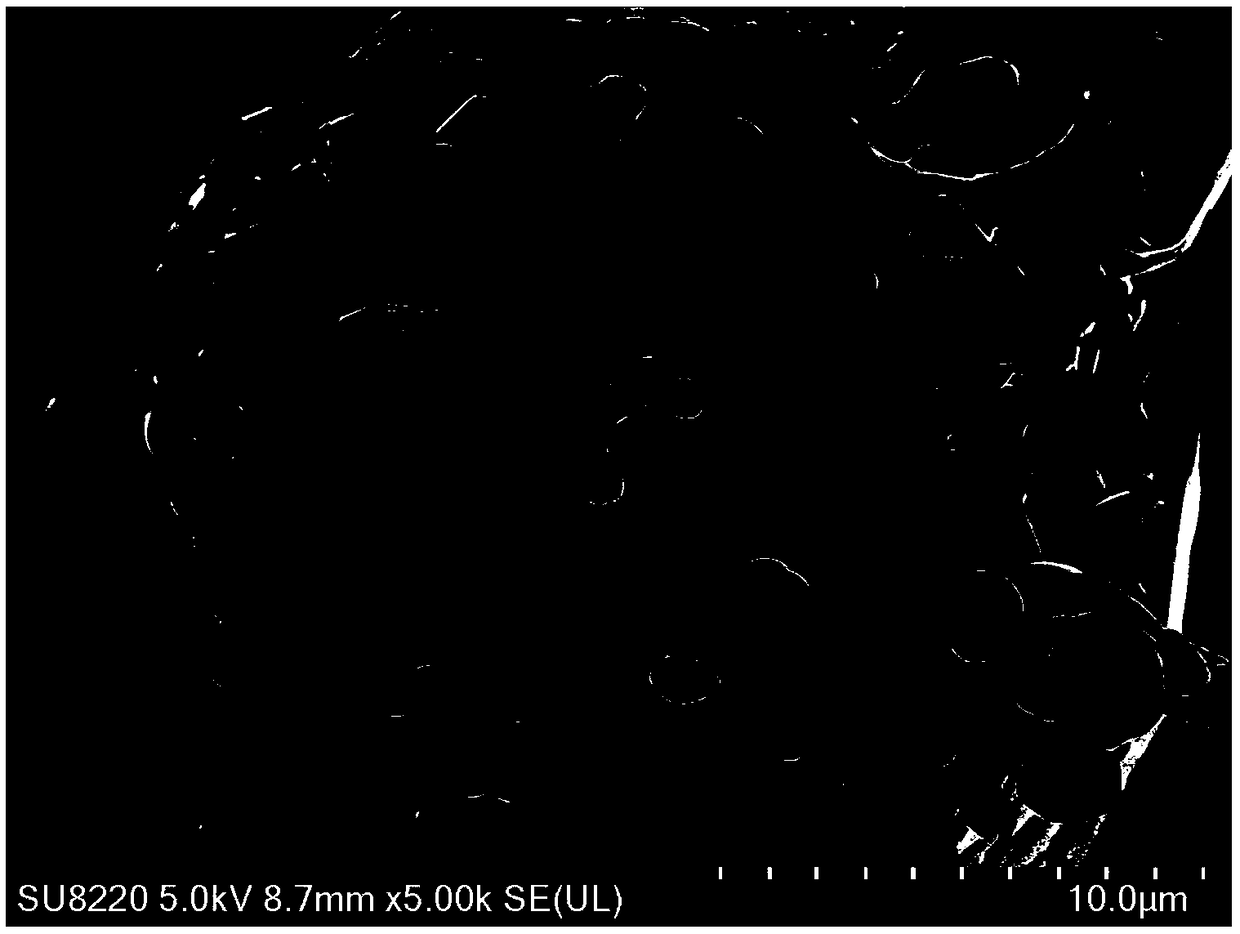

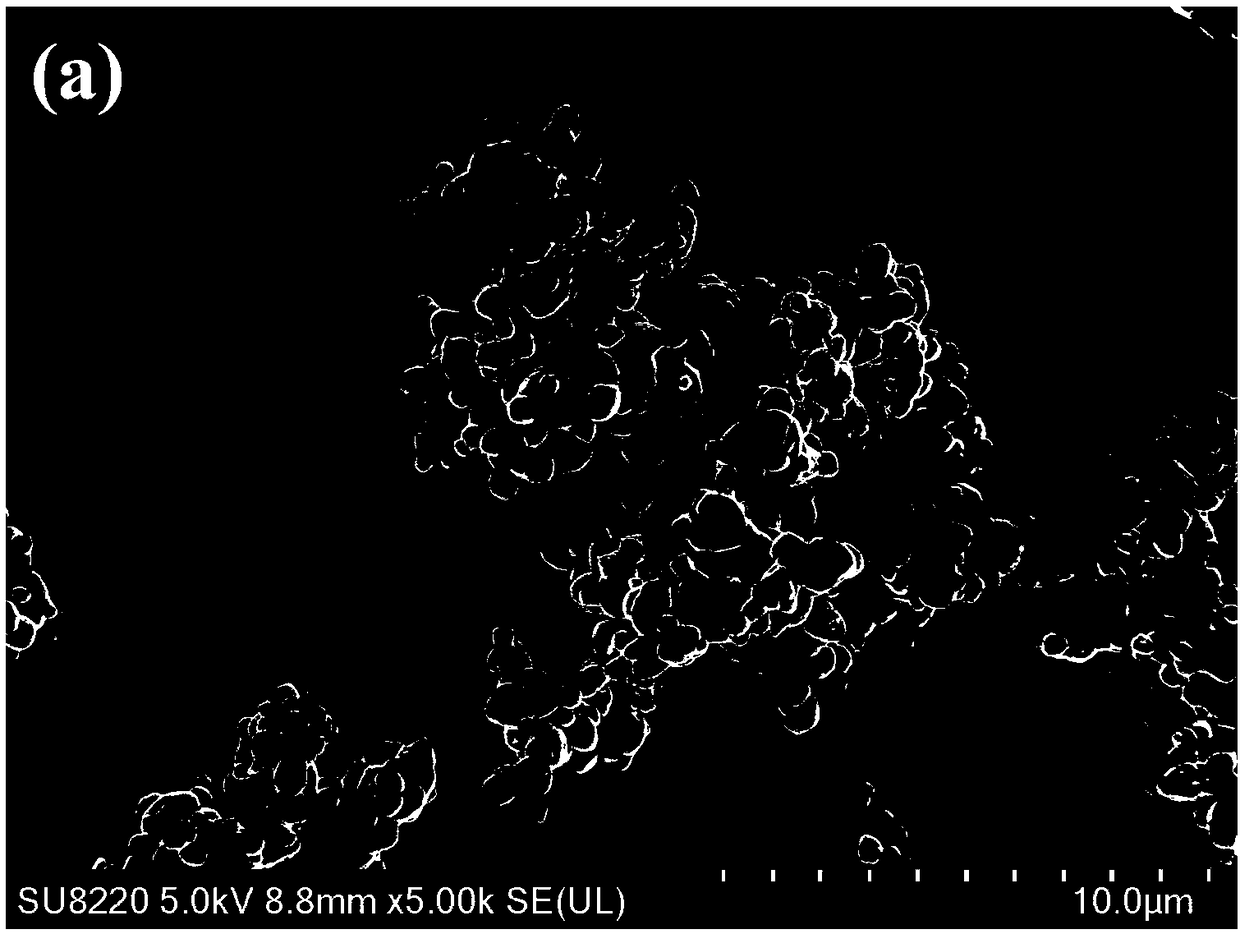

[0026] A preparation method utilizing carbon nanotubes to control the grain size of silver phosphate crystals, the steps are as follows:

[0027] (1) Weigh 1g of multi-walled carbon nanotubes (MWCNTs) in 350mL HNO 3 In the solution, reflux treatment was carried out under the condition of 120° C. while stirring, and the treatment time was 8 hours. After reflux, it was washed with ultrapure water until neutral, and dried in vacuum at 70°C.

[0028] (2) Weigh 0.0012g of MWCNTs obtained by drying into 40mL of ultrapure water, and sonicate for 3h.

[0029] (3) Weigh 1.53g AgNO 3 Dissolve in 30mL ultrapure water, add the solution dropwise to the above solution, and keep stirring in the dark for 12h;

[0030] (4) Weigh 1.074gNa 2 HPO 4 12H 2 O was dissolved in 30 mL of ultrapure water, and the solution was added dropwise to the solution obtained in step (3), and stirred for 6 h in the dark. The solid-liquid mixture was centrifuged, washed with ethanol and ultrapure water for 3...

Embodiment 2

[0036] The prepared Ag 3 PO 4 Monomer and Ag 3 PO4 @0.1%MWCNTs composite photocatalyst was used for the degradation of phenol to evaluate its photocatalytic activity. Accurately weigh 50 mg of the prepared materials into 100 mL of phenol solution with a concentration of 20 mg / L, stir continuously, and carry out the degradation reaction under the irradiation condition of 300W xenon lamp (λ>420nm). The solutions with different reaction times were taken for concentration determination, and the results were as follows: Figure 5 shown. It can be clearly seen that Ag 3 PO 4 The degradation ability of @MWCNTs is significantly better than that of Ag 3 PO 4 monomer. Image 6 for Ag 3 PO 4 and Ag 3 PO 4 The reaction kinetic curve corresponding to the degradation curve of phenol by @MWCNTs. As shown, the rate constant changes from 0.015min -1 Increase to 0.35min -1 , the photocatalytic rate of the composite photocatalyst is 19.4 times that of the monomer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com