CIGS glass substrate coating cleaning system

A glass substrate and cleaning system technology, applied in the field of automation, can solve problems such as scrapping of battery components, affecting the performance of thin-film batteries, short-circuiting of battery devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0113] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

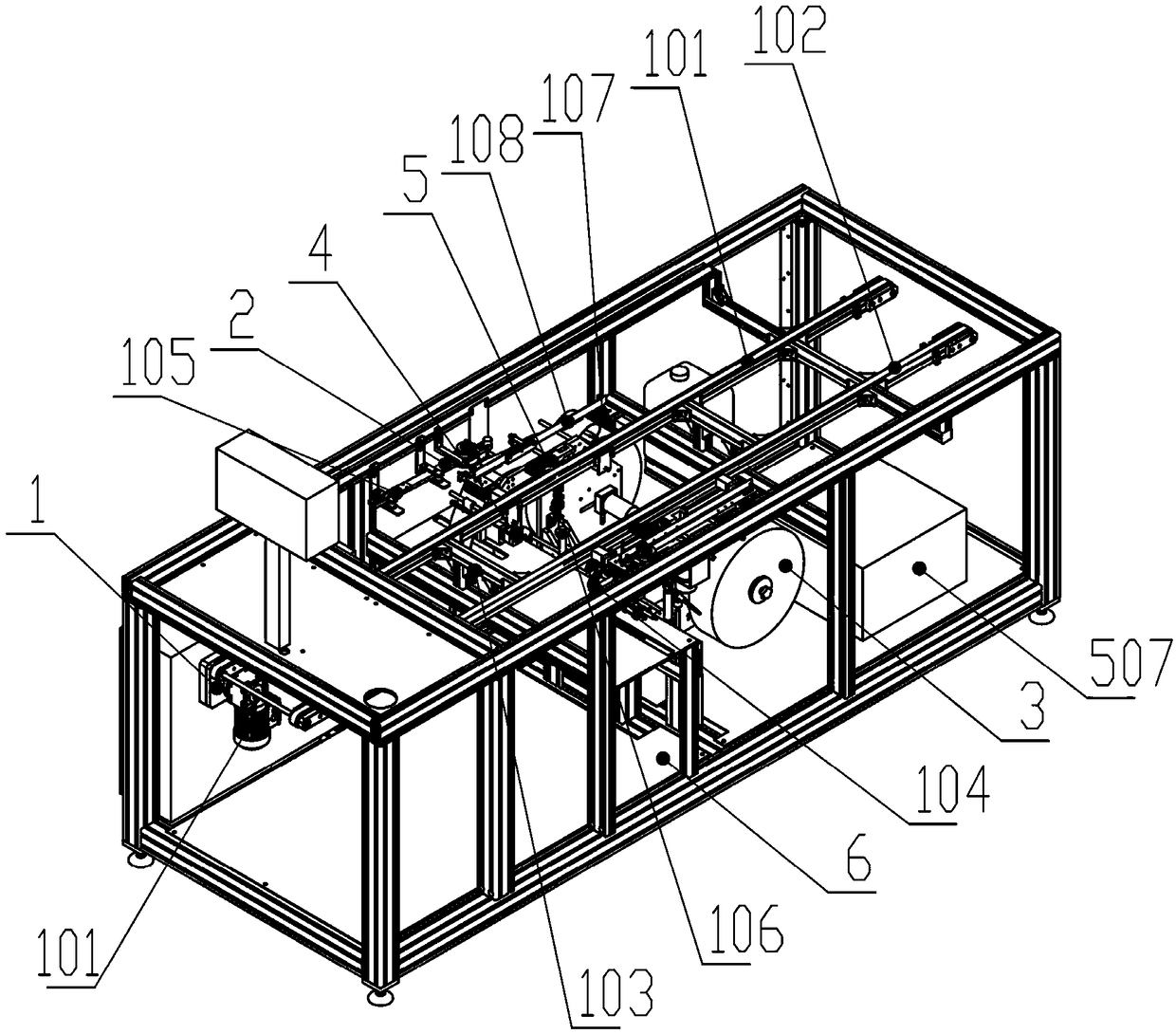

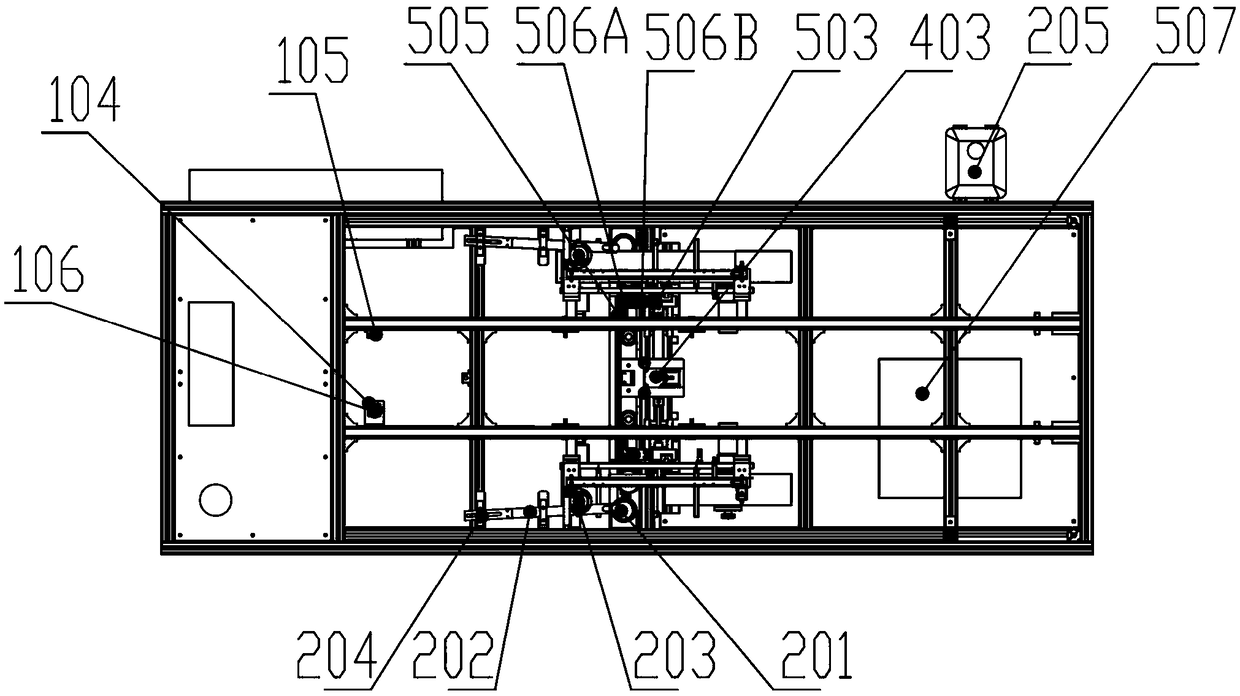

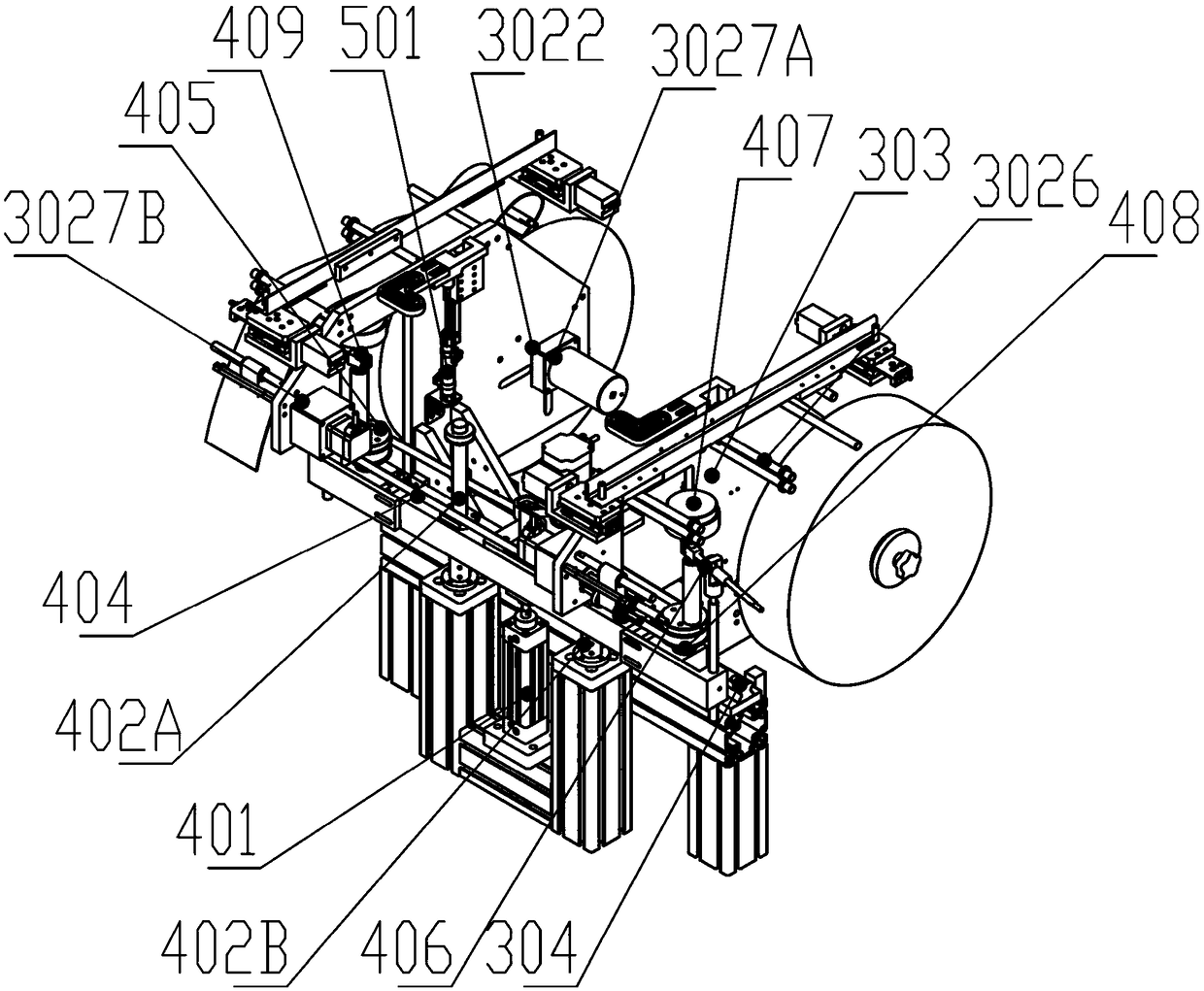

[0114] The structure of the CIGS glass substrate coating cleaning system is as follows: figure 1 , 2 as shown, figure 1 It is a schematic diagram of the three-dimensional structure of the CIGS glass substrate coating cleaning system of the present invention in an embodiment, figure 2 It is a top view of the CIGS glass substrate coating cleaning system of the present invention in an embodiment.

[0115] The CIGS glass substrate coating cleaning system, wherein the system includes:

[0116] Transport positioning mechanism 1, used for transporting and positioning the CIGS glass substrate;

[0117] The dripping mechanism 2 is used for evenly dripping the cleaning solution;

[0118] Cloth roll mechanism 3, the cleaning cloth roll is placed on the cloth roll mechanism 3, and the cloth roll mechanism 3 drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com