Treatment method of heavy metal waste water

A treatment method and technology for heavy metals, which are applied in water treatment parameter control, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of limited promotion, low removal rate of heavy metals, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

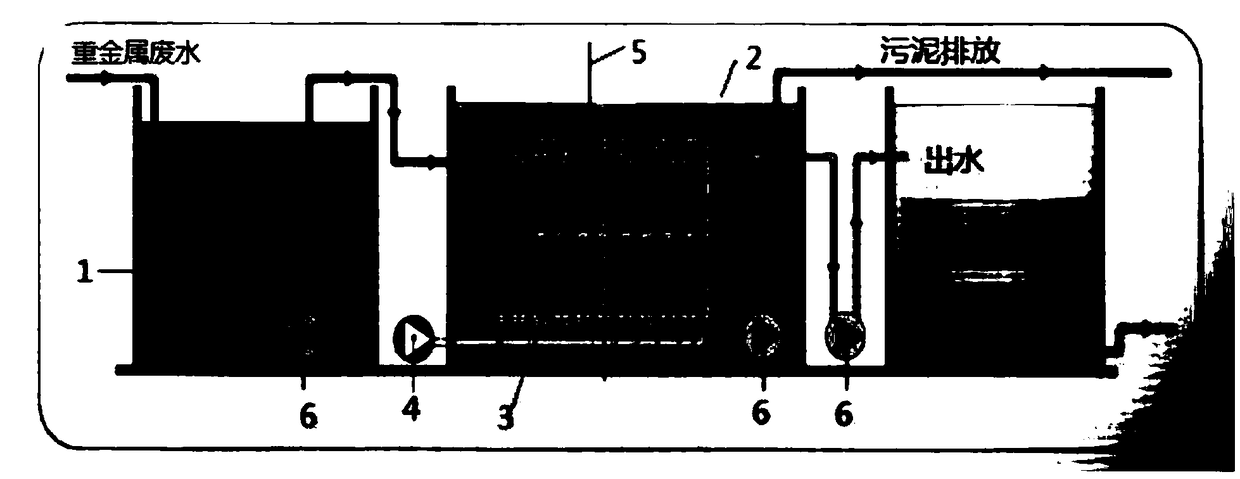

Image

Examples

Embodiment 1

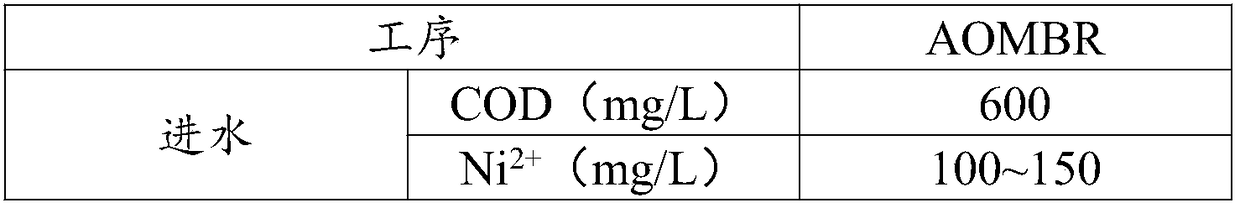

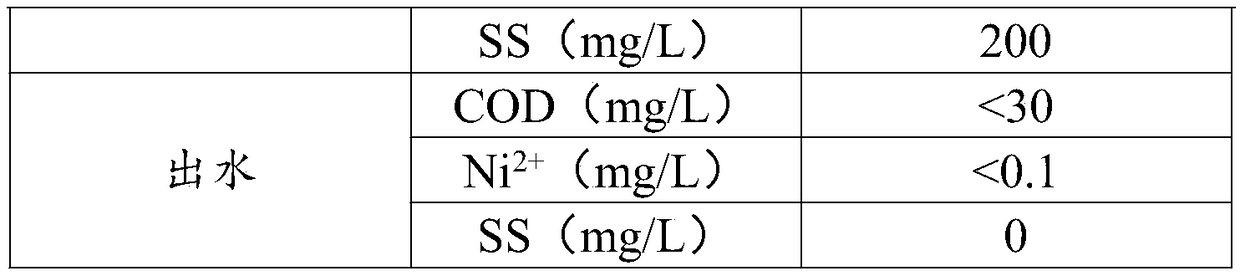

[0039] The initial content of COD in heavy metal wastewater is 600mg / L, Ni 2+ The initial content is 100-150mg / L, and the initial content of SS is 200mg / L;

[0040] The heavy metal wastewater is first homogenized through the regulating tank, and the hydraulic retention time of the heavy metal wastewater in the regulating tank is 10h;

[0041] The heavy metal wastewater treated in the regulating tank enters the anaerobic-aerobic integrated membrane bioreactor (hereinafter referred to as AOMBR). The membrane filaments filled in the reactor are hollow fiber membranes containing quinone groups. The sludge concentration in the AOMBR reactor It is 3000m g / L; AOMBR operates according to the following parameters: anaerobic treatment without aeration, hydraulic agitation for 1h, redox potential of -450mv; then aerobic treatment for 1h, aerobic treatment with aeration, no agitation, dissolved oxygen Controlled at 1mg / L, the aerobic treatment process passes through the membrane filament...

Embodiment 2

[0048] The initial content of COD in heavy metal wastewater is 310mg / L, Zn 2+ The initial content is 40mg / L, and the initial content of SS is 50mg / L;

[0049] The heavy metal wastewater is first homogenized through the regulating tank, and the hydraulic retention time of the heavy metal wastewater in the regulating tank is 12h;

[0050] The heavy metal wastewater treated in the regulating tank enters the anaerobic-aerobic integrated membrane bioreactor (hereinafter referred to as (AOMBR), the membrane filaments filled in the reactor are hollow fiber membranes containing quinone groups, and the sludge in the AOMBR reactor The concentration is 3000m g / L; AOMBR operates according to the following parameters: anaerobic treatment without aeration, hydraulic stirring for 50min, redox potential of -400mv; then aerobic treatment for 50min, aeration during aerobic treatment, no stirring, dissolved Oxygen is controlled at 2mg / L, and the aerobic treatment process passes through the memb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com