High concentration small water quantity biochemical sewage treatment system

A sewage treatment system, small water volume technology, applied in biological water/sewage treatment, neutralized water/sewage treatment, oxidized water/sewage treatment, etc., can solve anoxic or even anaerobic, sensory pollution, pollutant concentration Advanced problems, to achieve the effect of reducing the concentration of influent harmful substances, accelerating the rate of anaerobic reaction, and improving the efficiency of anaerobic reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following is a detailed description of the embodiments in conjunction with the drawings, but the provided embodiments are not used to limit the scope of the present invention, and the description of the structure and operation is not used to limit the order of execution. Any recombination of components Structures, resulting devices with equivalent functions are all within the scope of the present invention.

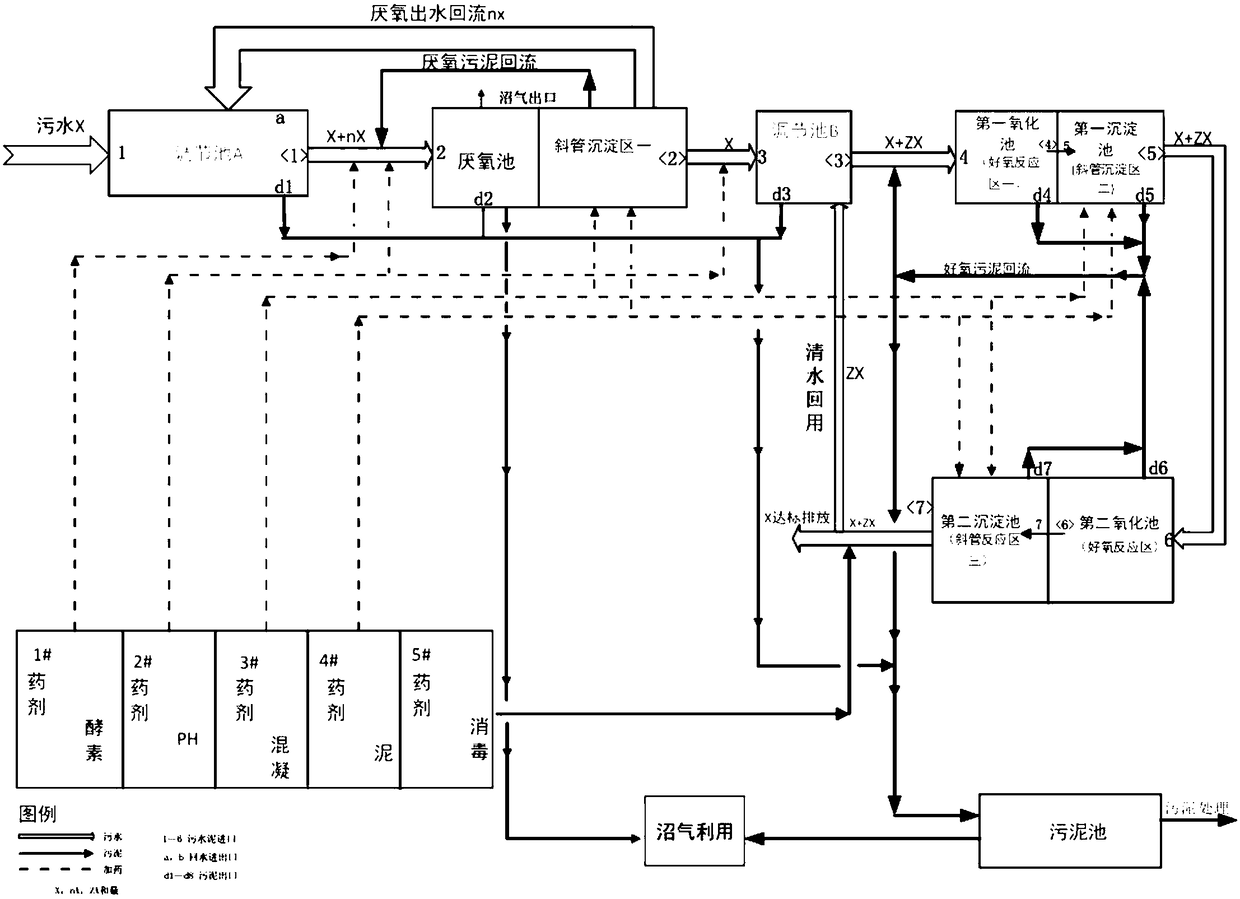

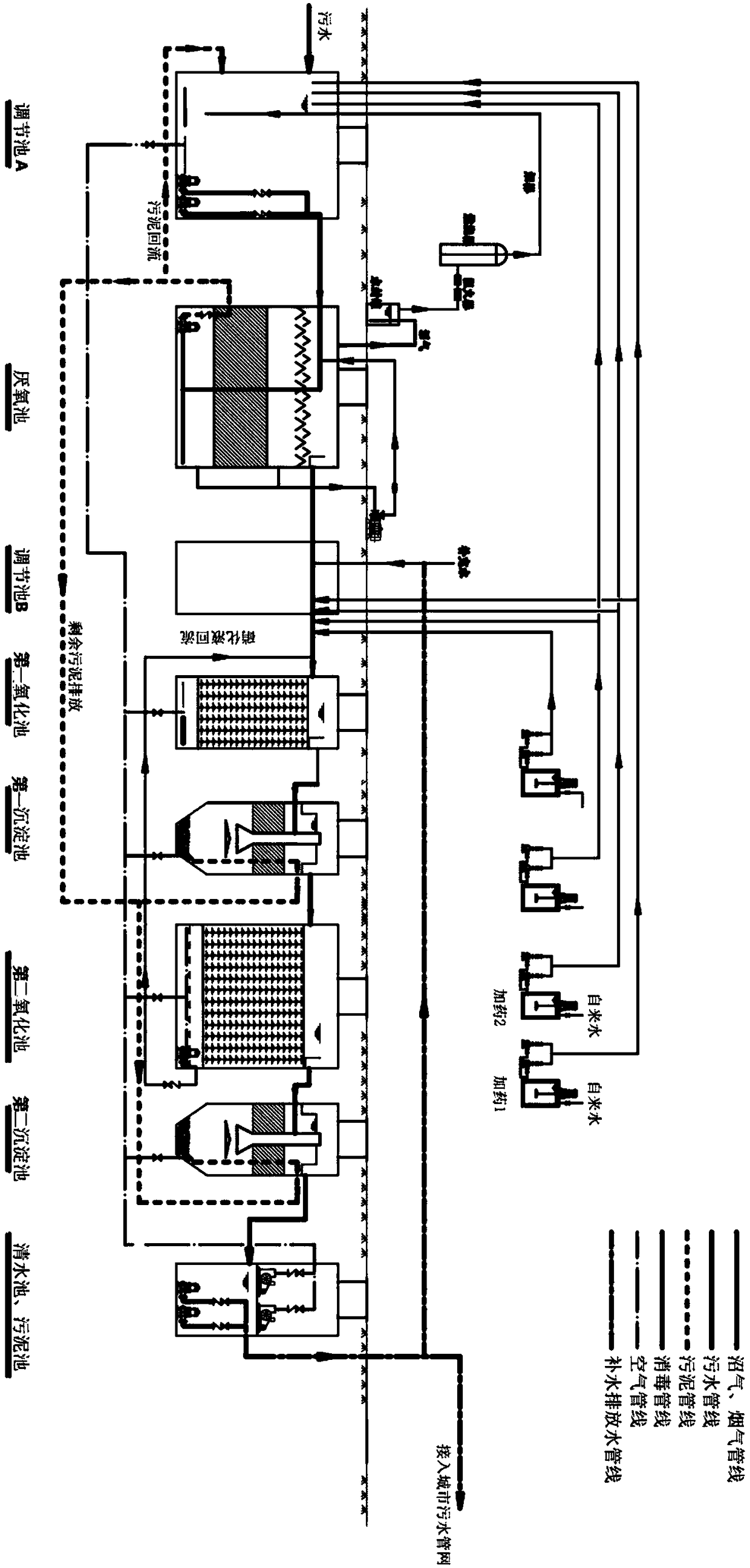

[0039] see figure 1 with figure 2 As shown, the high-concentration and small-volume biochemical sewage treatment system of the present invention includes an anaerobic section, and the anaerobic section includes a regulating tank A and an anaerobic tank. There is a second sewage outlet on the top of A, a second sludge outlet and a second sewage inlet at the bottom of the anaerobic tank, a biogas outlet at the top of the anaerobic tank, and the regulating tank A includes a sewage inlet, anaerobic sludge return flow The inlet, the sludge outlet, the dosing port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com