A kind of method for preparing nanometer microcrystalline cellulose cnc

A nano-microcrystalline and cellulose technology, applied in the field of pulp and paper making, can solve the problems of low yield, impact, poor thermal stability, etc., and achieve the effect of simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

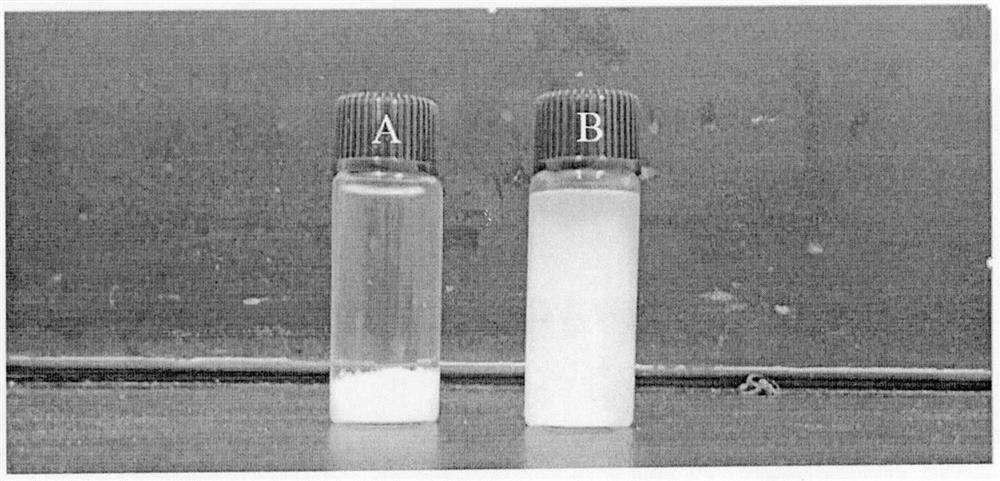

Image

Examples

Embodiment

[0016] Implementation example: use hydrochloric acid to hydrolyze bleached kraft hardwood pulp to prepare nanocellulose microcrystals, and use CTAB to improve its flocculation characteristics.

[0017] Step 1: shredding the bleached kraft hardwood pulp and treating it with a pulverizer to obtain fiber raw materials of 60 mesh or above;

[0018] Step 2: Weigh 10g of absolute dry fiber raw material, put it in a three-necked beaker, add 300mL of 3mol / L hydrochloric acid solution, immerse in an oil bath whose temperature has been adjusted to 110°C and react for 1.5h, while adjusting the mechanical stirring speed to 500rpm, After the reaction, a large amount of deionized water was added to terminate the reaction;

[0019] Step 3: After the reaction is over, add the suspension obtained in step 2) to 1000 mL of deionized water, stir evenly, then filter, and repeat 5 times;

[0020] Step 4: Centrifuge the suspension obtained in step 3 at a speed of 8000 rpm for 20 minutes to remove t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com