Rubber tube for car and manufacturing method thereof

A technology for rubber hoses and automobiles, which is applied in the direction of hoses, pipes, mechanical equipment, etc., and can solve problems such as poor bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

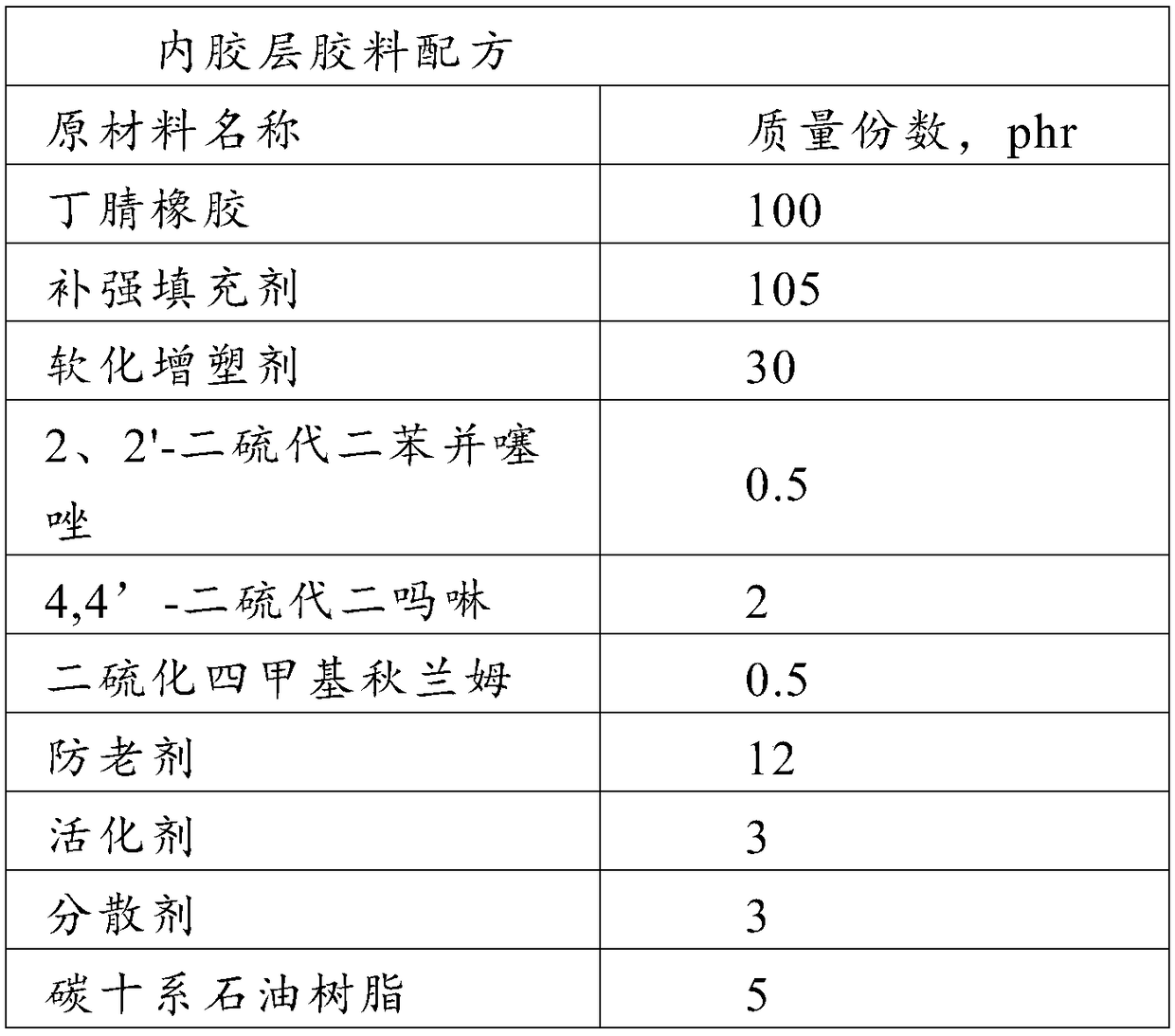

[0040] Table 1-1

[0041]

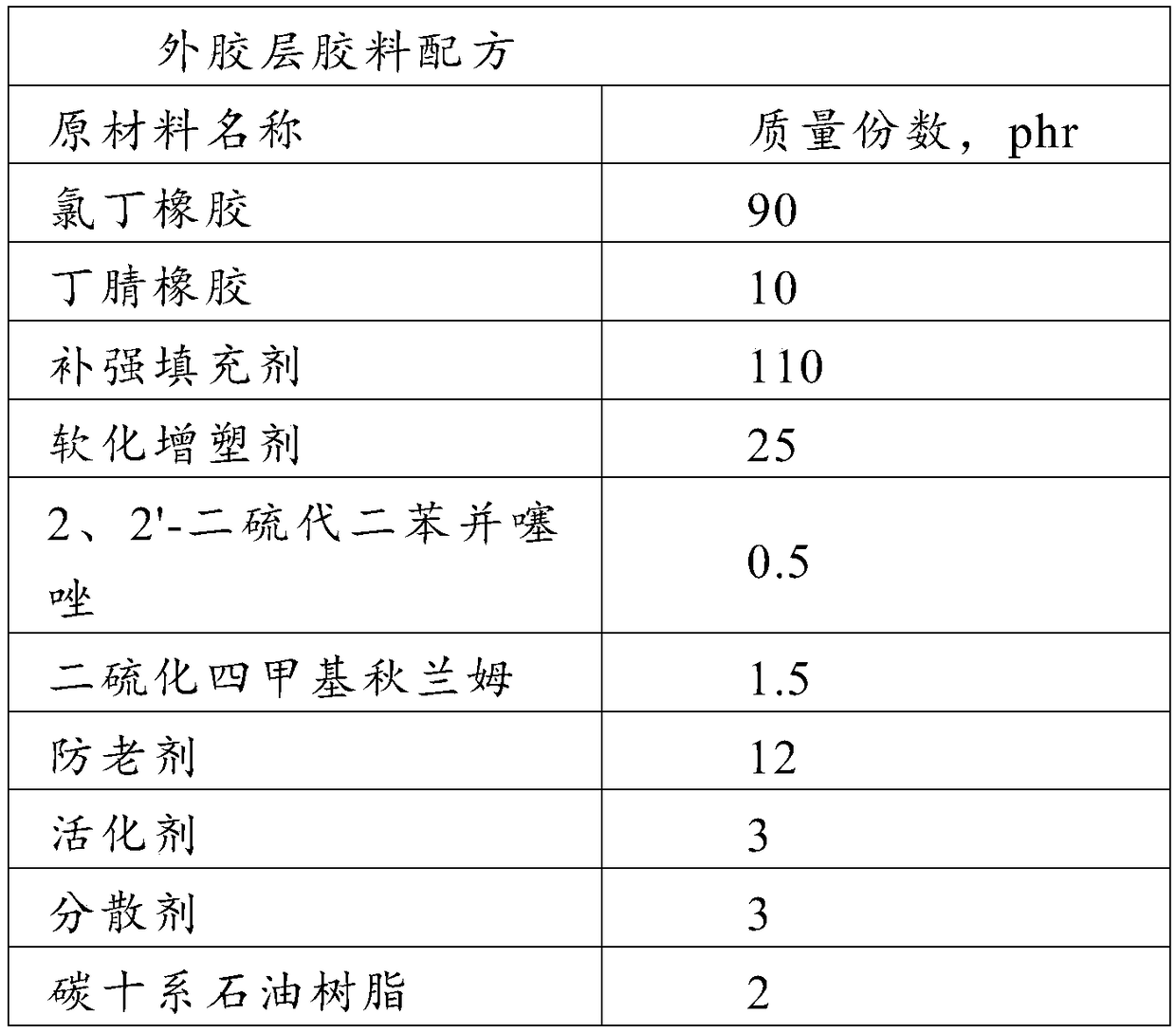

[0042] Table 1-2

[0043]

[0044] The process parameters are as follows:

[0045] 1. Hose size: inner diameter 9mm, wall thickness 4±0.4mm;

[0046] 2. Hose structure: with reinforced layer, using aramid in the middle;

[0047] 3. The rubber mixing is divided into two sections: the first section, the glue discharge temperature is 120°C; the second section, the glue discharge temperature is 100°C;

[0048] 4. Extrude inner rubber layer (¢90mm or ¢120mm pinless extruder): head 70°C, extrusion section 50°C, plasticizing section 50°C, feeding section 50°C, screw section 50°C;

[0049] 5. Hot oven: temperature 100°C;

[0050] 6. Extruded hose blank (¢90mm or ¢120mm pinless extruder): machine head 70°C, extrusion section 50°C, plasticizing section 50°C, feeding section 50°C, screw section 50°C;

[0051] 7. Vulcanization: 160±5°C, 30±5 minutes.

Embodiment 2

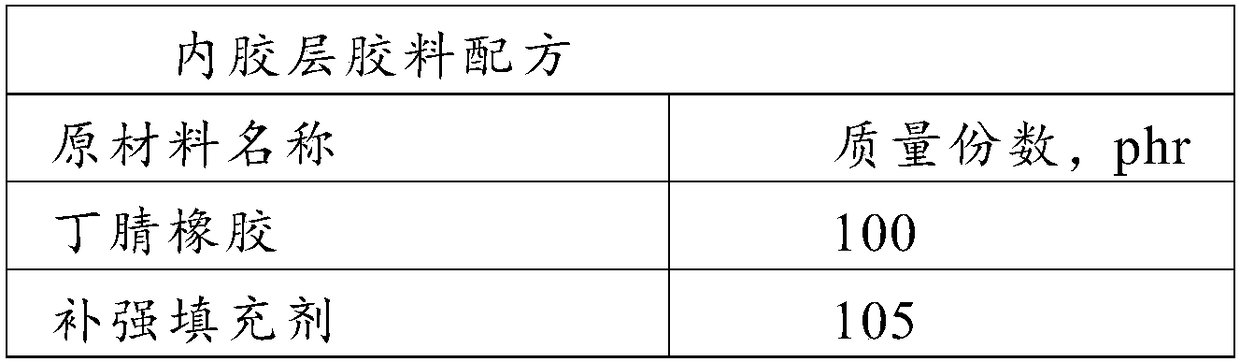

[0053] table 2-1

[0054]

[0055]

[0056] Table 2-2

[0057]

[0058] The process parameters are as follows:

[0059] 1. Hose size: inner diameter 9mm, wall thickness 4±0.4mm;

[0060] 2. Hose structure: with reinforced layer, using aramid in the middle;

[0061] 3. The rubber mixing is divided into two stages: the first stage, the glue discharge temperature is 120°C; the second stage, the glue discharge temperature is 100°C;

[0062] 4. Extrude inner rubber layer (¢90mm or ¢120mm pinless extruder): head 70°C, extrusion section 50°C, plasticizing section 50°C, feeding section 50°C, screw section 50°C;

[0063] 5. Hot oven: 200°C;

[0064] 6. Extruded hose blank (¢90mm or ¢120mm pinless extruder): machine head 70°C, extrusion section 50°C, plasticizing section 50°C, feeding section 50°C, screw section 50°C;

[0065] 7. Vulcanization conditions: 160±5°C, 30±5 minutes.

Embodiment 3

[0067] Table 3-1

[0068]

[0069] Table 3-2

[0070]

[0071]

[0072] The process parameters are as follows:

[0073] 1. Hose size: inner diameter 9mm, wall thickness 4±0.4mm;

[0074] 2. Hose structure: with reinforced layer, using aramid in the middle;

[0075] 3. The rubber mixing is divided into two stages: the first stage, the glue discharge temperature is 120°C; the second stage, the glue discharge temperature is 100°C;

[0076] 4. Extrude inner rubber layer (¢90mm or ¢120mm pinless extruder): head 70°C, extrusion section 50°C, plasticizing section 50°C, feeding section 50°C, screw section 50°C;

[0077] 5. Hot oven: temperature 300°C;

[0078] 6. Extruded hose blank (¢90mm or ¢120mm pinless extruder): machine head 70°C, extrusion section 50°C, plasticizing section 50°C, feeding section 50°C, screw section 50°C;

[0079] 7. Vulcanization conditions: 160±5°C, 30±5 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com