Preparation method of highly filled bible paper

A technology of bible paper and preparation steps, which is applied in the field of preparation of high-filling bible paper, can solve the problems of low retention rate of fillers, achieve high retention rate and opacity of fillers, improve uniformity and retention rate, The effect of uniform dispersion of fillers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

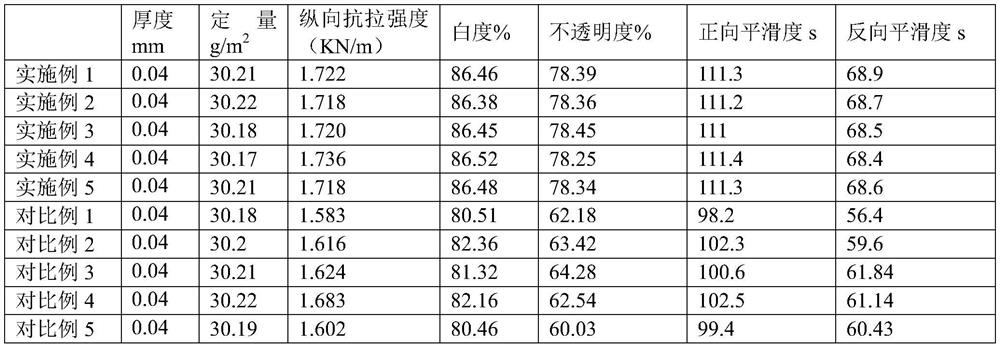

Examples

preparation example Construction

[0035] A preparation method for high-filling bible paper, comprising the following preparation steps:

[0036](1) Preparation of modified filler isocyanate-modified titanium dioxide: disperse titanium dioxide in ethanol, add aminopropyltriethoxysilane, stir and react for 0.8-1h to obtain amino-modified titanium dioxide; again disperse amino-modified titanium dioxide to N , into N-dimethylformamide, add hexamethylene diisocyanate, stir at 60-70°C for 3-4h to obtain modified filler; titanium dioxide, aminopropyl triethoxysilane and hexamethylene diisocyanate The molar ratio of isocyanate is 1:1-1.2:1-1.2.

[0037] (II) Beating: mix and beat the raw material slurry, modified fillers and auxiliary agents to form a mixed slurry; the raw material slurry includes 25-35% bleached sulfuric acid softwood pulp and 65-75% bleached sulfuric acid broadleaf pulp, The beating concentration is 4.0-5.0%, the beating degree of bleached kraft softwood pulp after beating is 65-75°SR, and the wet ...

Embodiment 1

[0044] A preparation method for high-filling bible paper, comprising the following preparation steps:

[0045] (1) Preparation of modified filler isocyanate-modified titanium dioxide: disperse titanium dioxide in ethanol, add aminopropyltriethoxysilane, stir and react for 0.9h to obtain amino-modified titanium dioxide; again disperse amino-modified titanium dioxide to N, Add hexamethylene diisocyanate to N-dimethylformamide, stir at 65°C for 3.5 hours to obtain a modified filler; the molar weight of titanium dioxide, aminopropyltriethoxysilane and hexamethylene diisocyanate The ratio is 1:1.1:1.1.

[0046] (II) Beating: Mix and beat the raw material slurry, modified fillers and auxiliary agents to form a mixed slurry; the raw material slurry includes 30% bleached sulfuric acid softwood pulp and 70% bleached sulfuric acid broadleaf pulp, and the beating concentration is 4.5%. After beating, the beating degree of bleached kraft softwood pulp is 70°SR, and the wet weight is 5.5g...

Embodiment 2

[0053] A preparation method for high-filling bible paper, comprising the following preparation steps:

[0054] (1) Preparation of modified filler isocyanate-modified titanium dioxide: disperse titanium dioxide in ethanol, add aminopropyltriethoxysilane, stir and react for 0.8h to obtain amino-modified titanium dioxide; again disperse amino-modified titanium dioxide to N, In N-dimethylformamide, add hexamethylene diisocyanate and stir at 60°C for 3 hours to obtain a modified filler; the molar ratio of titanium dioxide, aminopropyltriethoxysilane and hexamethylene diisocyanate 1:1.2:1.

[0055] (II) Beating: Mix and beat the raw material slurry, modified fillers and auxiliary agents to form a mixed slurry; the raw material slurry includes 25% bleached sulfuric acid softwood pulp and 75% bleached sulfuric acid broadleaf pulp, and the beating concentration is 4.0%. After beating, the beating degree of bleached kraft softwood pulp is 65°SR, and the wet weight is 4g; the beating de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| opacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com