Preparation method of plant coloring agent

A plant dye, plant technology, applied in dyeing methods, chemical instruments and methods, azo dyes, etc., can solve the problems of difficulty in batch growth, high price, low extraction rate, etc. The effect of high yield and purity, extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

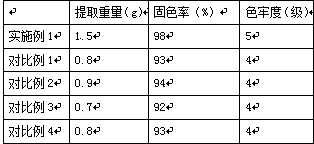

Examples

Embodiment 1

[0026] A kind of preparation method of plant coloring agent, concrete steps are as follows:

[0027] 1) After crushing the plants, pass through a 50-mesh sieve, soak in 15% dilute sulfuric acid solution, heat to 50°C, and soak for 35 minutes to obtain acid hydrolyzed material;

[0028] 2) Move the acid hydrolyzed material into a sealed container, pass through high-pressure steam to heat for 30 minutes, and then quickly release the pressure to atmospheric pressure to obtain the puffed material;

[0029] 3) Soak the puffed material in 4% 1-butyl-3-methylimidazolium acetate ionic liquid, heat it to 110°C for 30 minutes, and obtain the pretreated material;

[0030] 4) Take out the pretreatment material, soak it in a sodium hydroxide solution with a concentration of 3-5%, move it to a container of 50KPa, freeze it at -15°C for 15 minutes, then heat it to 30°C, and add a compound enzyme to carry out the enzyme Decompose for 25 minutes, then reduce the pressure to 30KPa, raise the t...

Embodiment 2

[0042] A kind of preparation method of plant coloring agent, concrete steps are as follows:

[0043] 1) After crushing the plants, pass through a 50-mesh sieve, soak in 17% dilute sulfuric acid solution, heat to 53°C, and soak for 37 minutes to obtain acid hydrolyzed material;

[0044] 2) Move the acid hydrolyzed material into a sealed container, pass in high-pressure steam for heating for 32 minutes, and then quickly release the pressure to atmospheric pressure to obtain the puffed material;

[0045] 3) Soak the puffed material in 1-butyl-3-methylimidazolium acetate ionic liquid with a concentration of 5%, heat it to 130°C for 35 minutes, and obtain the pretreated material;

[0046] 4) Take out the pretreated material, soak it in a 4% sodium hydroxide solution, move it to a 60KPa container, freeze it at -17°C for 17 minutes, then heat it to 32°C, add a compound enzyme for enzymolysis for 27 minutes , then lower the pressure to 35KPa, raise the temperature to 38°C, and contin...

Embodiment 3

[0058] A kind of preparation method of plant coloring agent, concrete steps are as follows:

[0059] 1) After crushing the plants, pass through a 50-mesh sieve, soak in 20% dilute sulfuric acid solution, heat to 55°C, and soak for 40 minutes to obtain acid hydrolyzed material;

[0060] 2) Move the acid hydrolyzed material into a sealed container, pass through high-pressure steam to heat for 35 minutes, and then quickly release the pressure to atmospheric pressure to obtain the puffed material;

[0061] 3) Soak the puffed material in 1-butyl-3-methylimidazolium acetate ionic liquid with a concentration of 7%, heat it to 150°C for 40 minutes, and obtain the pretreated material;

[0062] 4) Take out the pretreated material, soak it in a 5% sodium hydroxide solution, move it to a container at 70KPa, freeze it at -20°C for 20 minutes, then heat it to 35°C, add a compound enzyme for enzymolysis for 30 minutes , then reduce the pressure to 40KPa, raise the temperature to 40°C, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com