Water-based UV anti-corrosive coating and preparation method thereof

A kind of anti-corrosion coating, water-based technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of reinforced concrete corrosion, construction quality problems, construction raw materials, etc., achieve fast curing speed, easy to master the preparation process, and low preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

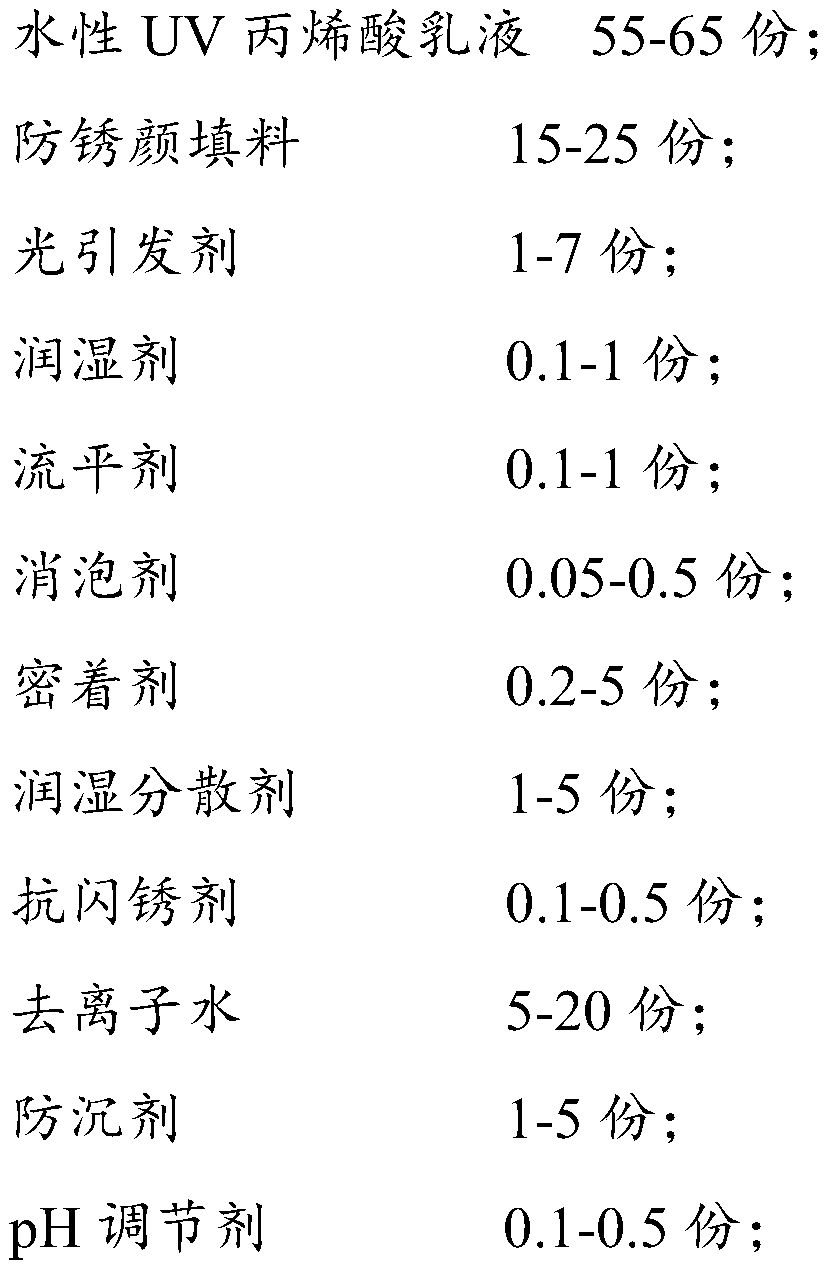

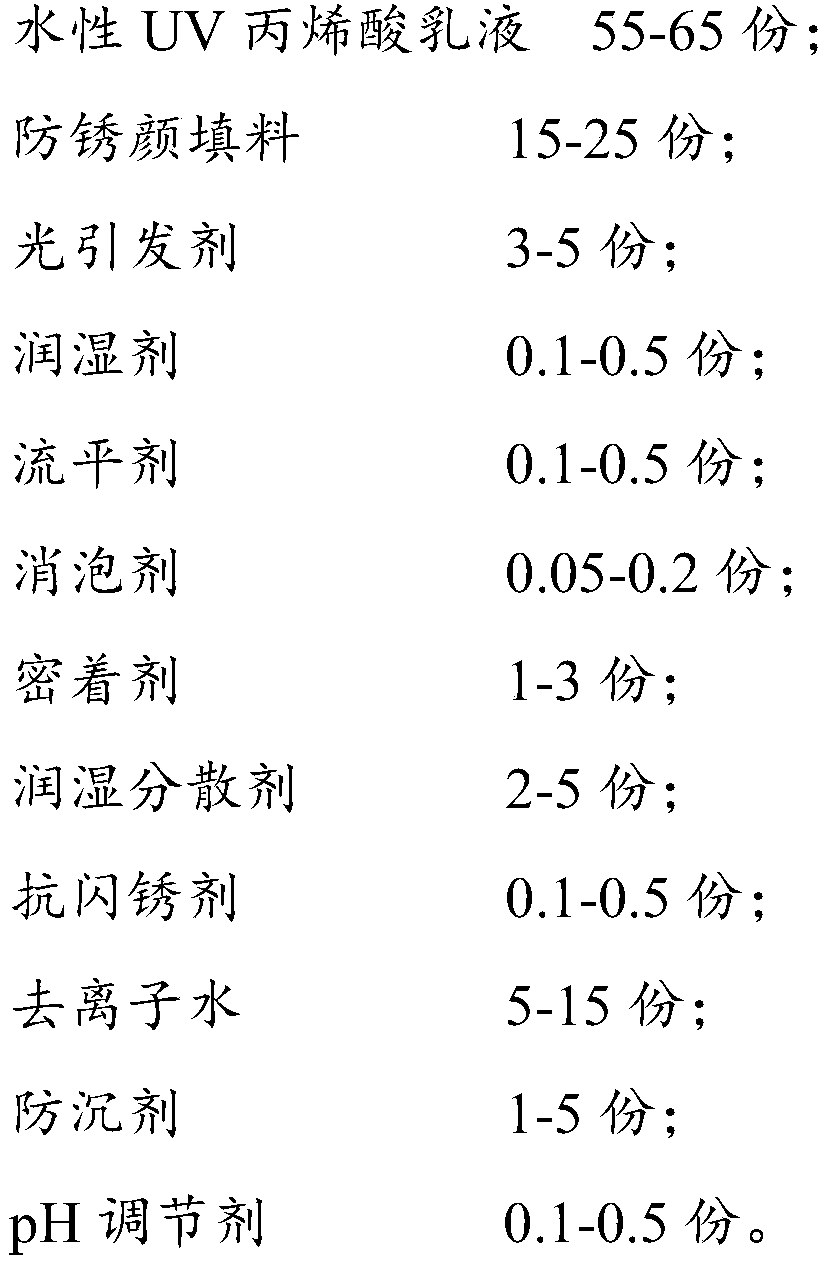

Method used

Image

Examples

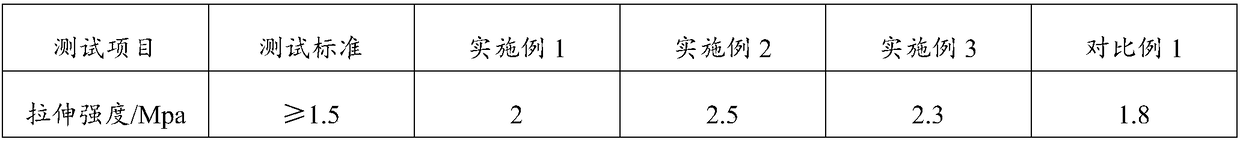

Embodiment 1

[0034] A kind of water-based UV anticorrosion coating, its preparation process is as follows:

[0035] (1) Mix 39.8 parts of water-based UV acrylic emulsion (Wanhua Chemical wantipro0618), 10 parts of zinc phosphate, 10 parts of aluminum tripolyphosphate, 6 parts of talcum powder, 14 parts of titanium dioxide, 6 parts of titanium iron powder, and 9 parts of deionized Put water, 5 parts of wetting and dispersing agent, and 0.2 parts of defoamer into the dispersion tank and stir at low speed (400-800 rpm) for 10-20 minutes to prepare the slurry, and use a sand mill to grind to 30 μm or less to obtain 100 parts anti-rust slurry;

[0036] (2) 38.15 parts of water-based UV acrylic emulsion (wanhua chemical wantipro0618), 50 parts of the anti-rust slurry, 5 parts of deionized water, 3 parts of photoinitiator, 0.2 part of anti-flash rust agent, 0.2 part of wetting Add 0.15 parts of leveling agent, 1 part of adhesion agent, and 2 parts of anti-settling agent into the reactor. After t...

Embodiment 2

[0038] A kind of water-based UV anticorrosion paint, its preparation process is as follows:

[0039] (1) 49.8 parts of water-based UV acrylic emulsion (Wanhua chemical wantipro0614), 12 parts of zinc phosphate, 8 parts of aluminum tripolyphosphate, 4 parts of talcum powder, 10 parts of titanium dioxide and 4 parts of titanium iron powder, 7 parts of deionized Put water, 5 parts of wetting and dispersing agent, and 0.2 parts of defoamer into the dispersion tank and stir at low speed (400-800 rpm) for 10-20 minutes to prepare the slurry, and use a sand mill to grind to 30 μm or less to obtain 100 parts anti-rust slurry;

[0040](2) 40.15 parts of water-based UV acrylic emulsion (Wanhua Chemical wantipro0614), 45 parts of anti-rust slurry, 6 parts of deionized water, 4 parts of photoinitiator, 0.2 part of anti-flash rust agent, 0.2 part of wetting agent , 0.15 parts of leveling agent, 1 part of adhesion agent, and 3 parts of anti-settling agent are put into the reactor, and afte...

Embodiment 3

[0042] A kind of water-based UV anticorrosion paint, its preparation process is as follows:

[0043] (1) Mix 35 parts of water-based UV acrylic emulsion (Huajinsi HD2083), 11 parts of zinc phosphate, 9 parts of aluminum tripolyphosphate, 5 parts of talcum powder, 12 parts of titanium dioxide, 5 parts of titanium iron powder, and 8 parts of deionized Put water, 10 parts of wetting and dispersing agent, and 0.4 parts of defoaming agent into the dispersion tank and stir at low speed (400-800 rpm) for 10-20 minutes to prepare the slurry, and use a sand mill to grind it to 30 μm or less to obtain rust prevention slurry;

[0044] (2) 45 parts of water-based UV acrylic emulsion (Huajinsi HD2083), 42 parts of the antirust slurry, 8 parts of deionized water, 5 parts of photoinitiator, 0.3 part of anti-flash rust agent, 0.5 part of wetting Add 0.5 parts of leveling agent, 3 parts of adhesion agent, and 3 parts of anti-settling agent into the reaction kettle. After the medium speed (900...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com