Magneto-controlled sputter coating production line

A magnetron sputtering coating and production line technology, which is applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve problems such as difficulty in stabilizing the sputtering environment atmosphere, easy occurrence of pinholes, and performance differences. Achieve the effect of high infrared absorption/reflectivity and good heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

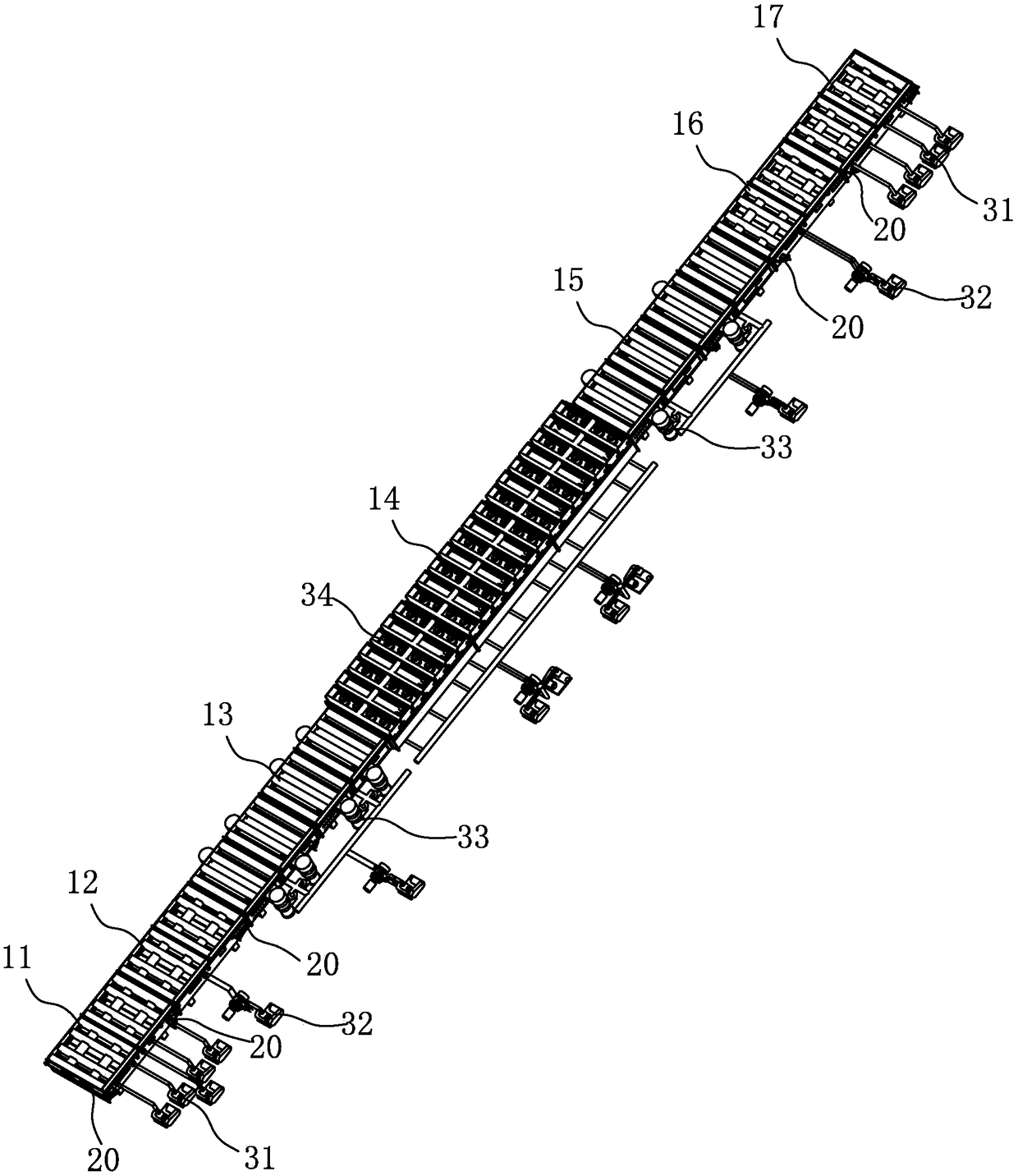

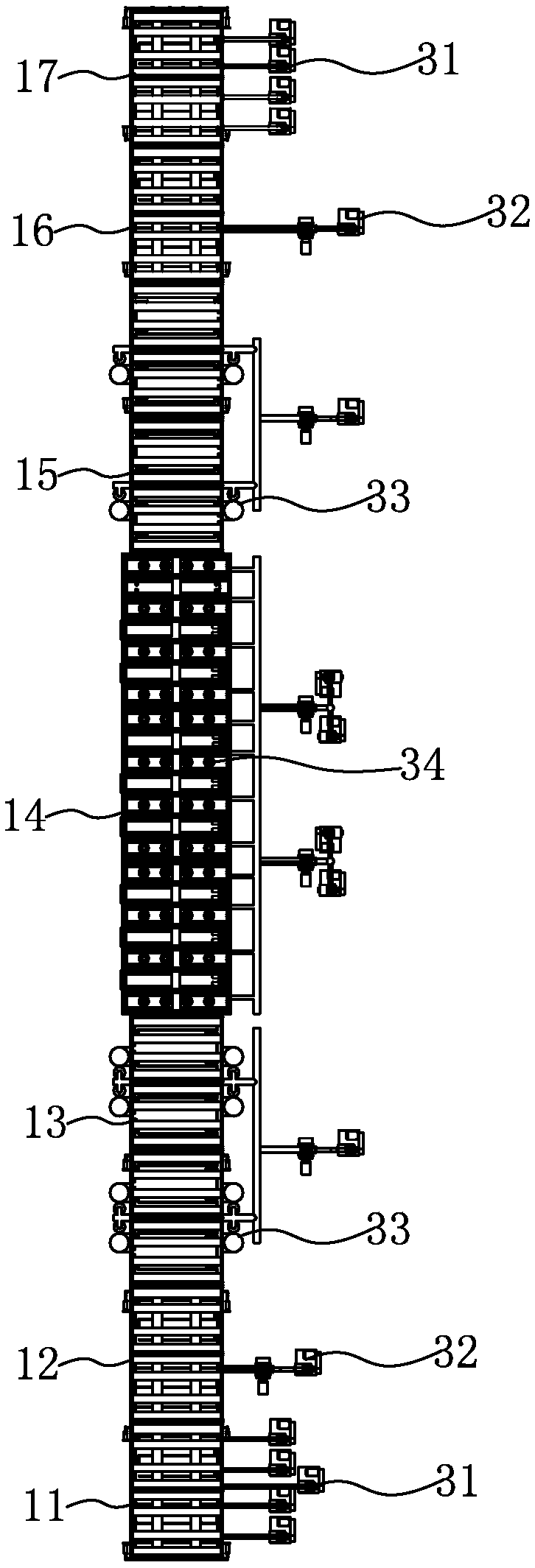

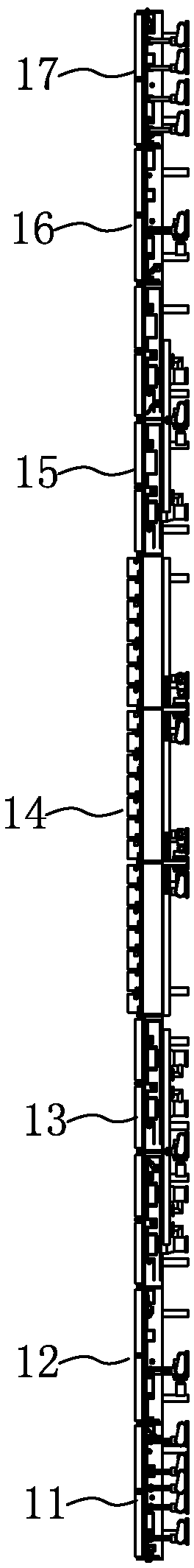

[0029] Such as Figure 1 to Figure 10 It is a drawing of an embodiment of the present invention.

[0030] A magnetron sputtering coating production line, such as Figure 1 to Figure 5 As shown, it includes a vertical vacuum chamber 10, and the vertical vacuum chamber 10 includes a film feed chamber 11, a film feed buffer chamber 12 located at the discharge end of the film feed chamber 11, and a film feed transition located at the discharge end of the film feed buffer chamber 12. Chamber 13, the coating chamber 14 that is located at the discharge end of the transition chamber 13, the transition chamber 15 that is located at the discharge end of the coating chamber 14, the buffer chamber 16 that is located at the discharge end of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com