Open type joint inner side waterproof sealing structure of stone curtain wall and construction method

A technology of stone curtain wall and waterproof structure, applied in the direction of walls, building components, building structures, etc., can solve problems such as poor waterproof effect, and achieve the effect of low quality and safety risk, reasonable design and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

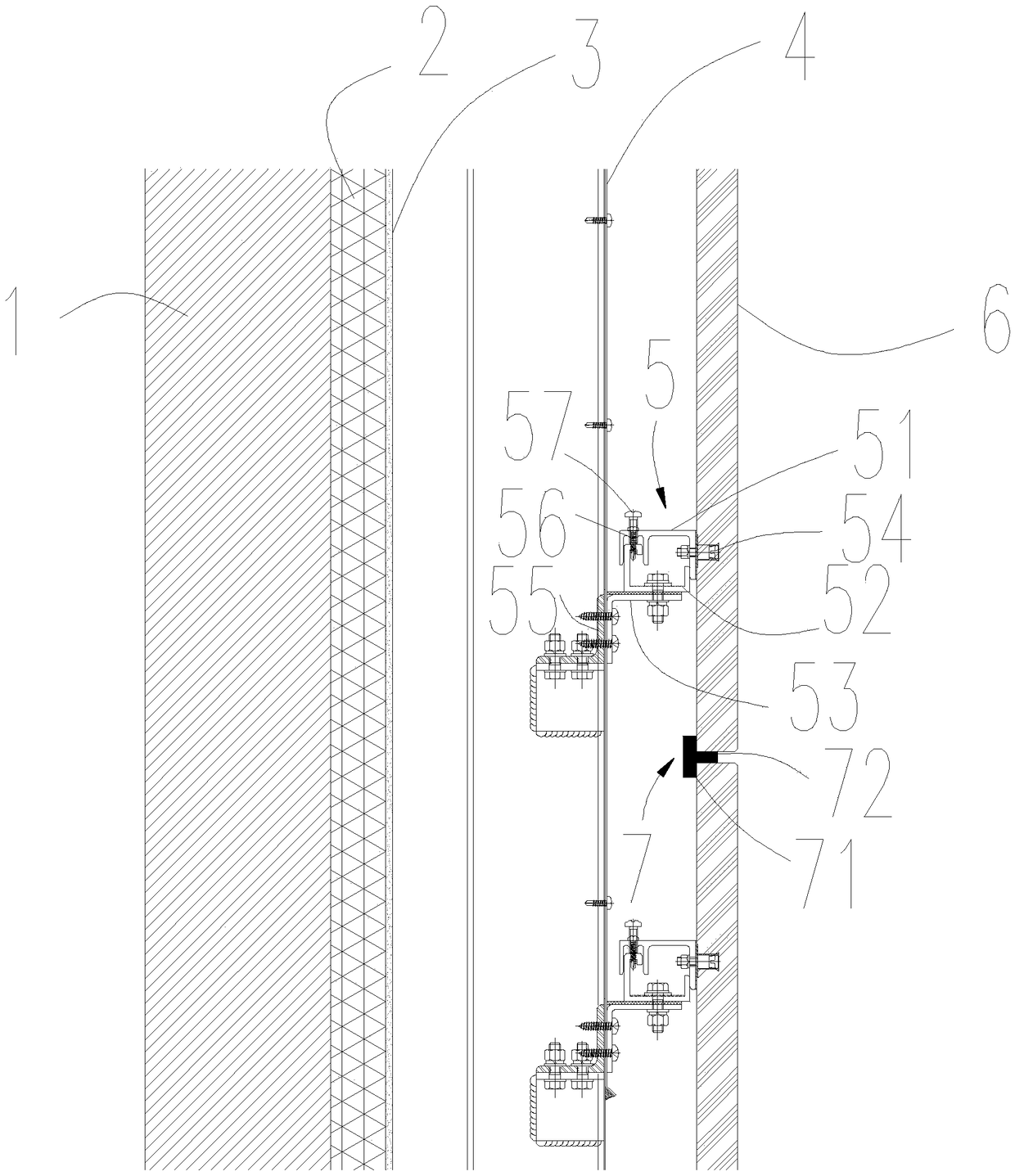

[0025] Such as figure 1 As shown, the present invention is an open stone curtain wall joint inner waterproof structure, which includes a civil structure 1, a thermal insulation layer 2 and a waterproof layer 3 arranged in sequence, and a galvanized iron sheet water retaining plate 4 is arranged on the outer side of the waterproof layer 3, The galvanized iron sheet water retaining plate 4 is fixedly connected with the civil structure 1 through connectors, and the galvanized iron sheet water retaining plate 4 is provided with a plurality of connection assemblies 5, and the connection assembly 5 is provided with a plurality of stone curtain wall panels 6, Each stone curtain wall panel 6 is pressed, and a T-shaped EPDM strip 7 is arranged between adjacent stone curtain wall panels 6; the T-shaped EPDM strip 7 includes a horizontal part 71 and a vertical part 72; The height of the portion 72 is half of the thickness of the stone curtain wall panels 6 , and the thickness of the vert...

Embodiment 2

[0031] A construction method of the waterproof structure inside the joints of the open stone curtain wall described in Embodiment 1, comprising the following steps:

[0032] 1) According to the design drawings, use 3D software to deepen the setting of the open curtain wall, and calculate the length of the stone curtain wall to be installed in the horizontal and vertical directions and the number of stone curtain wall panels;

[0033] 2) Install and install the insulation layer and waterproof layer on the outside of the civil structure in turn, install and fix the galvanized iron water retaining board on the civil construction structure, and install various connecting components on the galvanized iron water retaining board;

[0034] 3) Install each stone curtain wall panel on the connection assembly, install T-shaped EPDM strips between adjacent stone curtain wall panels, and check the compactness and bonding of the T-shaped EPDM strips at the same time To ensure the sealing ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com