An optical direct current measuring device for high voltage direct current transmission

A technology of high-voltage direct current transmission and direct current, applied in the direction of measuring devices, measuring only current, measuring electrical variables, etc., can solve the problems of easy burning and failure of laser emitting devices, harsh working environment, and easy damage, etc., to avoid heat generation problem, avoid tip discharge, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be further introduced in detail below in conjunction with the accompanying drawings of the description.

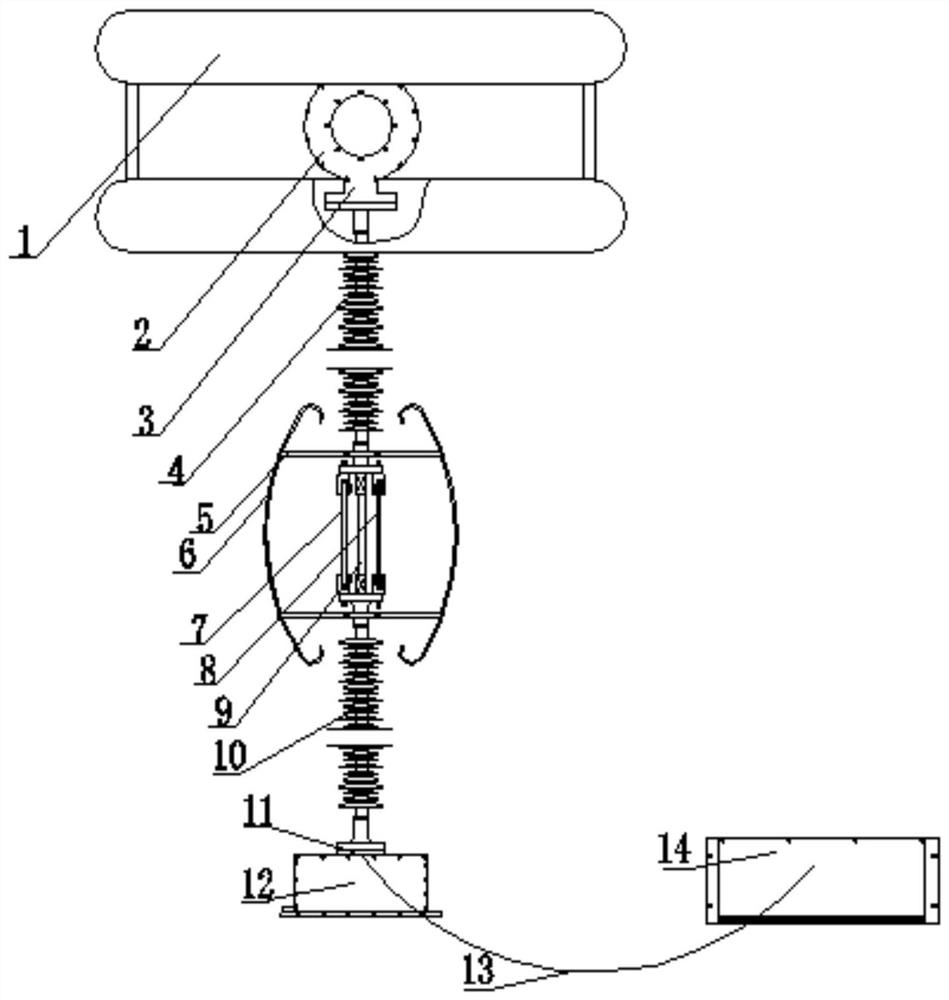

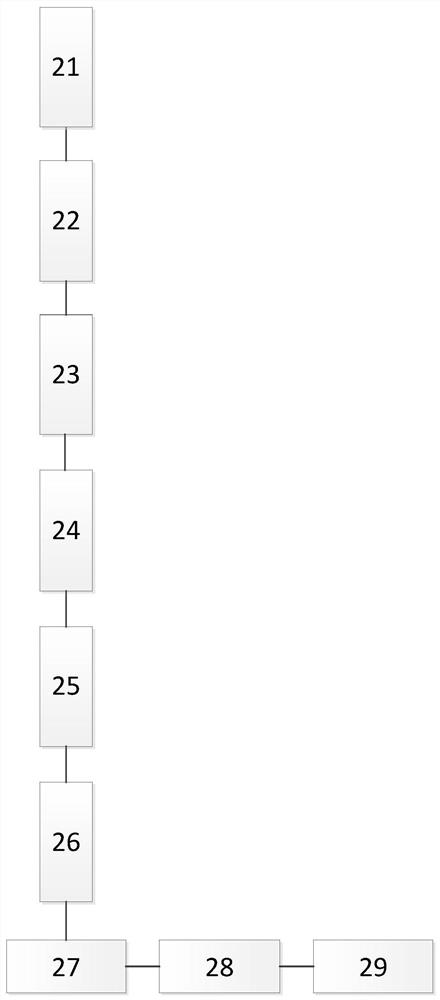

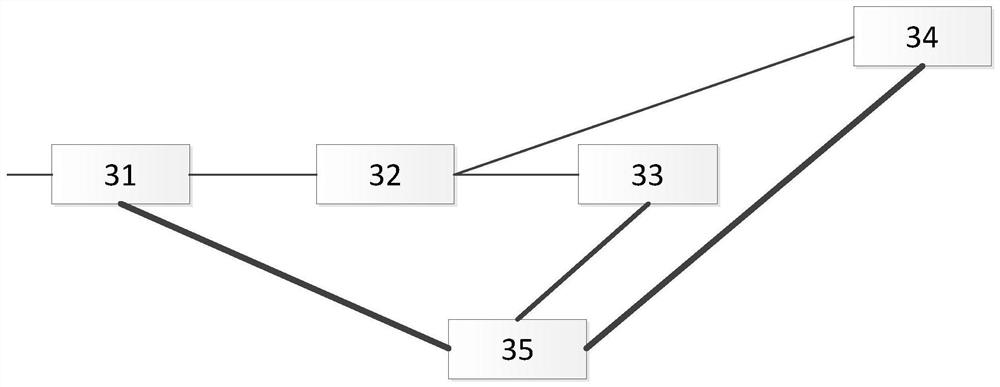

[0041] figure 1 Schematic diagram of the optical DC current measurement device for HVDC transmission, figure 2 It is the schematic diagram of the sensing circuit of the 800kV flexible DC current measuring device, image 3 It is the composition diagram of the high-speed modulation and demodulation unit of the 800kV flexible DC current measuring device, Figure 4 It is the working flow diagram of the 800kV flexible DC current measuring device.

[0042] The invention discloses an optical direct current measuring device for high-voltage direct current transmission, which comprises a sensing optical fiber ring body 2, an upper flange structure 3, an upper equalizing ring 1, an upper high-voltage polarization-maintaining optical fiber insulator 4, and a middle equalizing ring 6 , the middle pressure equalizing ring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com