Sensitive equipment voltage sag tolerance characteristic testing and data processing method

A technology for voltage sag and characteristic testing, which is applied in the direction of measuring electricity, measuring devices, and measuring electrical variables, etc. It can solve the problems of experimental testing, difficulty in obtaining quantitative results of equipment sag tolerance, and inability to reflect the degree of influence of sensitive equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below with reference to the accompanying drawings.

[0054] The detailed reasoning analysis method and demonstration analysis examples are disclosed below. However, the specific reasoning and analysis process details disclosed herein are only for the purpose of describing exemplary analysis examples.

[0055] However, it should be understood that the present invention is not limited to the disclosed specific exemplary embodiments, but covers all modifications, equivalents, and alternatives falling within the scope of the present disclosure. In the description of all the drawings, the same reference numerals denote the same elements.

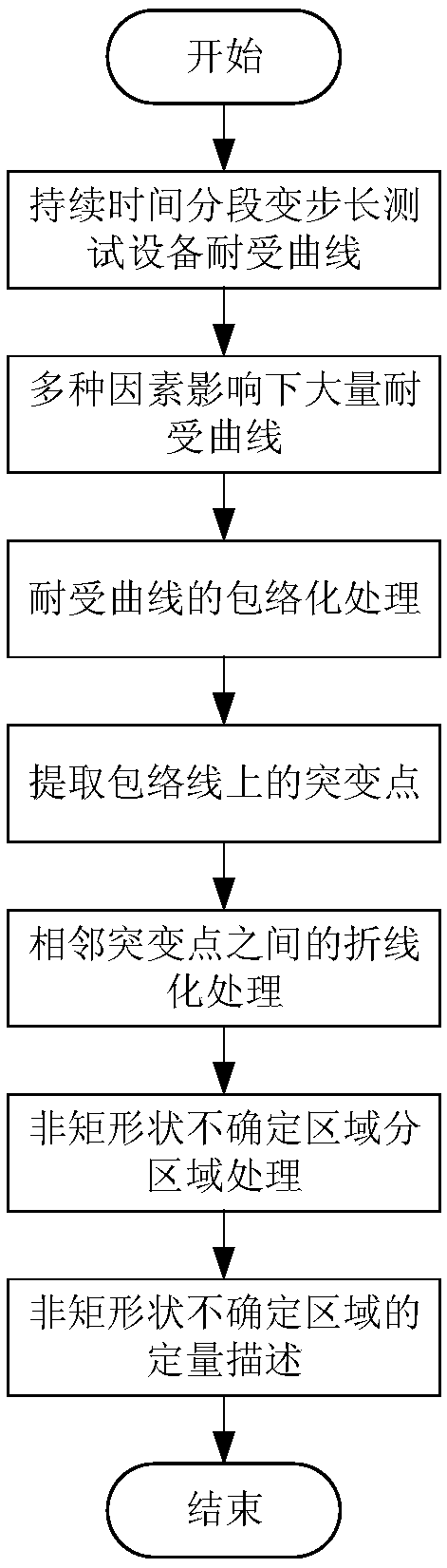

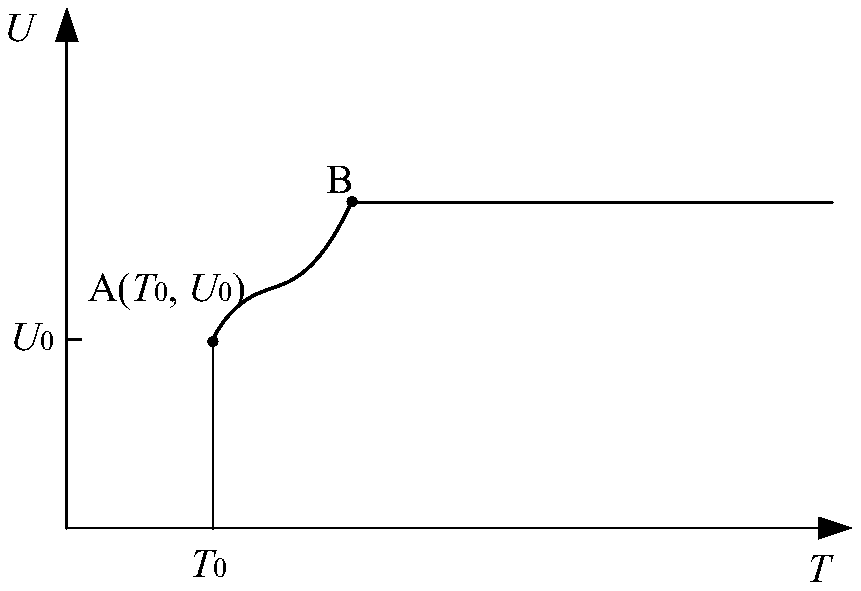

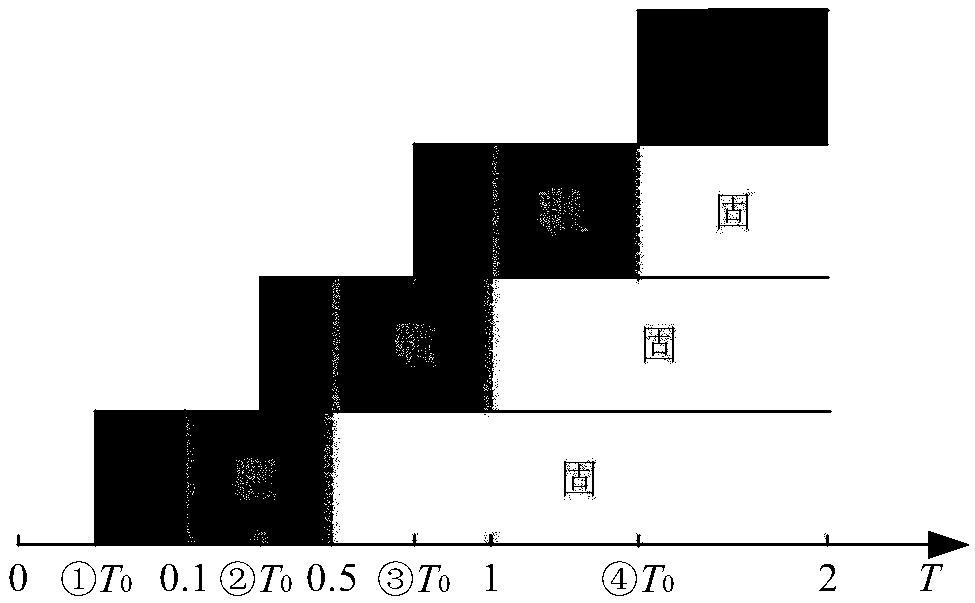

[0056] Such as figure 1 As shown, a voltage sag withstand characteristic test and data processing method for sensitive equipment includes the following steps:

[0057] A. Set the sag test point by changing the duration step by step;

[0058] B. Envelope and broken line treatment of equipment tolera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com