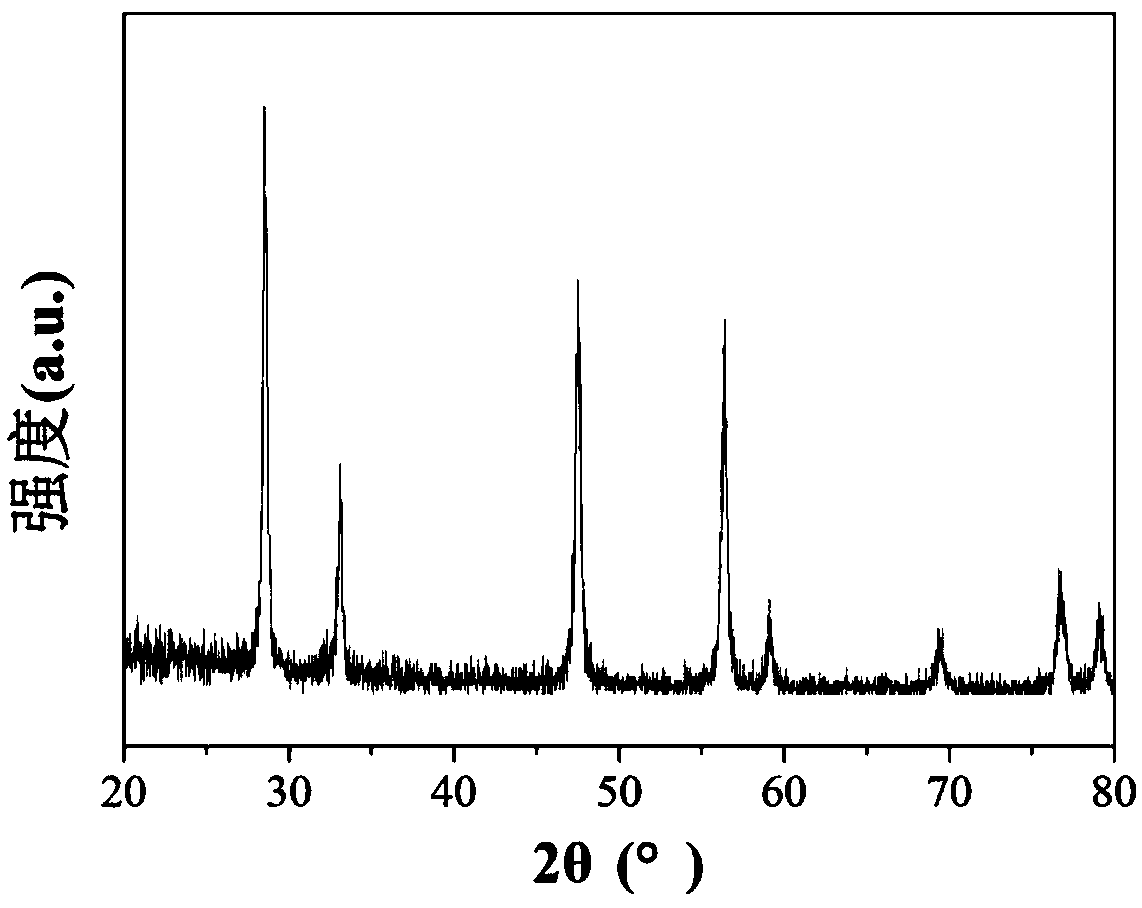

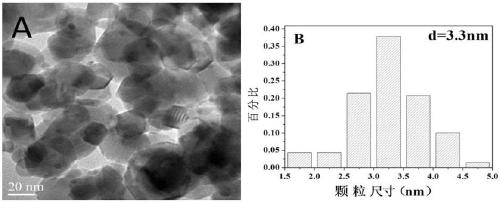

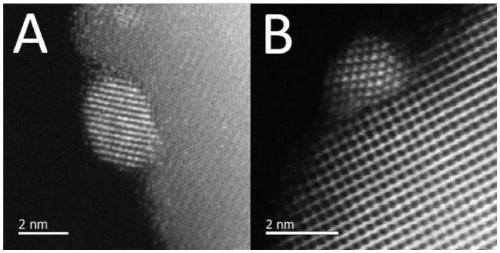

Loaded alloy catalyst for selective hydrogenation of alkyne and preparation method thereof

An alloy catalyst and selective technology, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of higher requirements on carrier structure and composition, and achieve excellent The effect of catalytic activity, good selectivity, and mild reaction process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A. Add 1.96g Ce(NO 3 ) 2 ·6H 2 O solid, 1.58 mL of Na with a concentration of 50 mmol / L 2 PdCl 4 solution and 0.79 mL of HAuCl with a concentration of 50 mmol / L 4 The solution was dispersed in 50 mL deionized water to prepare solution A.

[0032] B. Weigh 0.56g NaOH and dissolve it in 50mL deionized water to prepare solution B.

[0033] C. At room temperature, drop the lye and salt solution into a reactor containing 50ml of deionized water with a syringe and a peristaltic pump device respectively and keep stirring. The drop rate of the salt solution is 200ml / h, and the drop rate of the lye solution is 280ml / h, keep the pH of the solution at 10.0, continue to stir for 30 minutes after the dropwise addition, and place the obtained black suspension in an 80°C oil bath for static aging for 3 hours. The supernatant was filtered off, and centrifuged and washed five times to make the supernatant neutral. Dry it in a constant temperature oven at 80°C for 12 hours to obt...

Embodiment 2

[0035] A. Add 1.96g Ce(NO 3 ) 2 ·6H 2 O solid, 0.24g Cu(NO 3 ) 2 ·3H 2 O solid, 1.58 mL of H at a concentration of 50 mmol / L 2 PdCl 4 The solution was dispersed in 50 mL deionized water to prepare solution A. Weigh 0.56g NaOH and dissolve it in 50mL deionized water to prepare Solution B.

[0036] B. Take a syringe and a peristaltic pump device, drop the lye and the salt solution respectively at room temperature into a reactor containing 50ml of deionized water and keep stirring, the drop rate of the salt solution is 180ml / h, and the drop rate of the lye solution is 220ml / h, the pH of the solution was maintained at 9.0. After the dropwise addition of the solution, the stirring was continued for 30 min, and then the obtained black suspension was placed in an oil bath at 60° C. for static aging for 6 h. The supernatant was filtered off, and centrifuged and washed five times to make the supernatant neutral. Put it in a constant temperature oven and dry it at 80°C for 12...

Embodiment 3

[0038] A. Add 1.96g Ce(NO 3 ) 2 ·6H 2 O solid, 0.021g RuCl 3 ·3H 2 O solid, 2.37 mL of Na with a concentration of 50 mmol / L 2 PdCl 4 The solution was dispersed in 50 mL deionized water to prepare solution A. Weigh 0.56g NaOH and dissolve it in 50mL deionized water to prepare Solution B.

[0039] B. Take a syringe and a peristaltic pump device, drop the lye and the salt solution respectively at room temperature into a reactor containing 50ml of deionized water and keep stirring, the drop rate of the salt solution is 180ml / h, and the drop rate of the lye solution is 220ml / h, the pH of the solution was maintained at 9.0. After the dropwise addition of the solution was completed, the stirring was continued for 30 min, and then the obtained black suspension was placed in an 80° C. oil bath for static aging for 3 h. The supernatant was filtered off, and centrifuged and washed five times to make the supernatant neutral. Put it in a constant temperature oven and dry it at 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com