Three-dimensional elliptical ultrasonic vibration cutting device adopting longitudinal bending composite mode

A technology of ultrasonic vibration cutting and compound mode, which is applied in the direction of fluid using vibration, can solve problems such as difficult-to-machine materials and parts with weak rigidity, and achieve the effects of less adjustment links, improved power output capability, and convenient processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

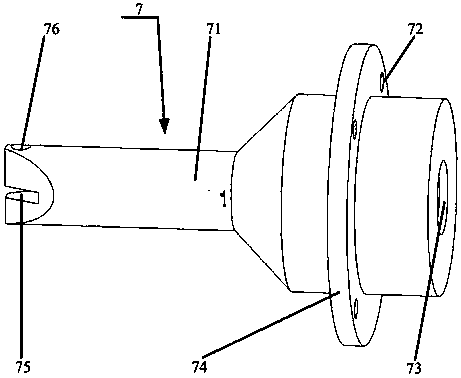

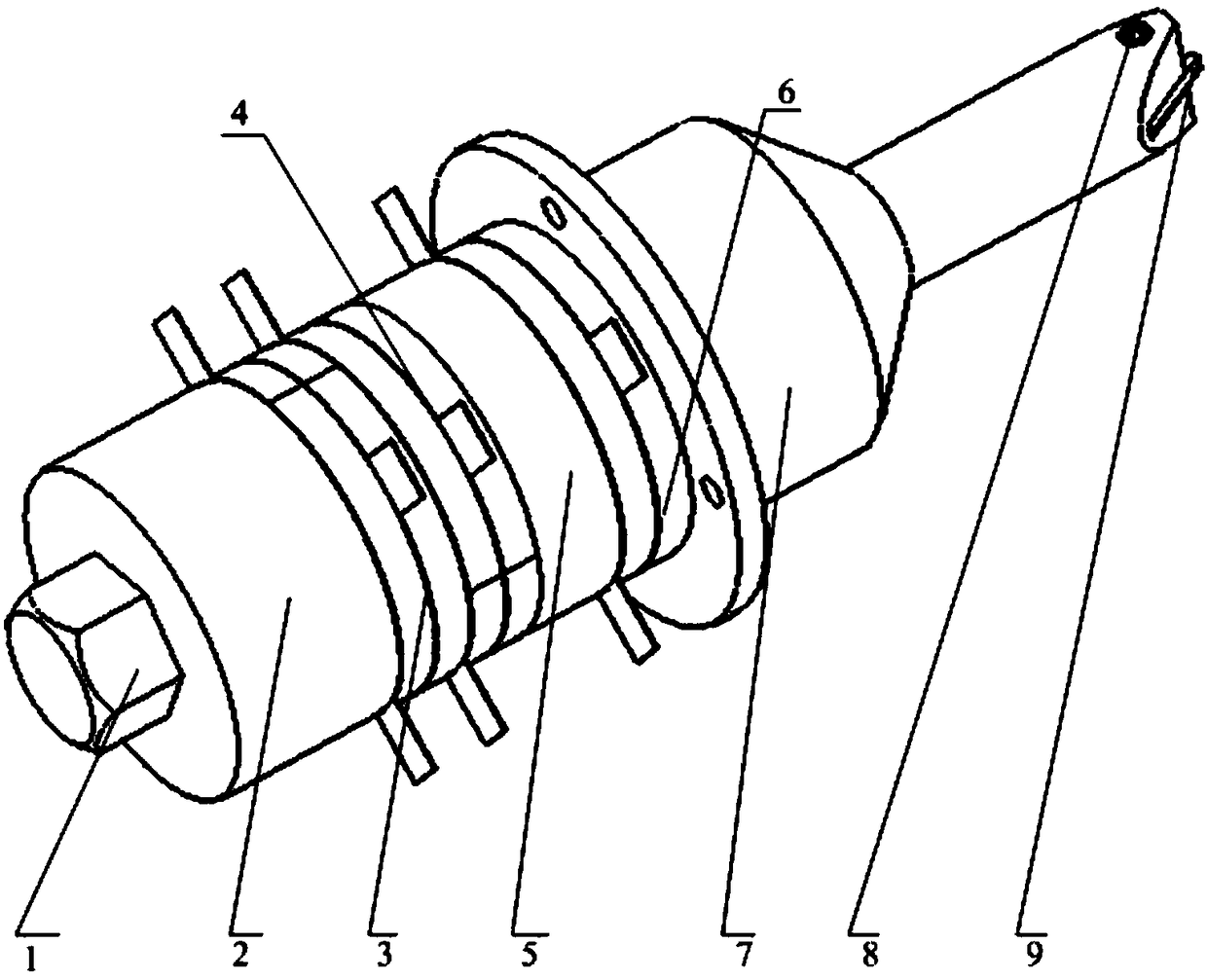

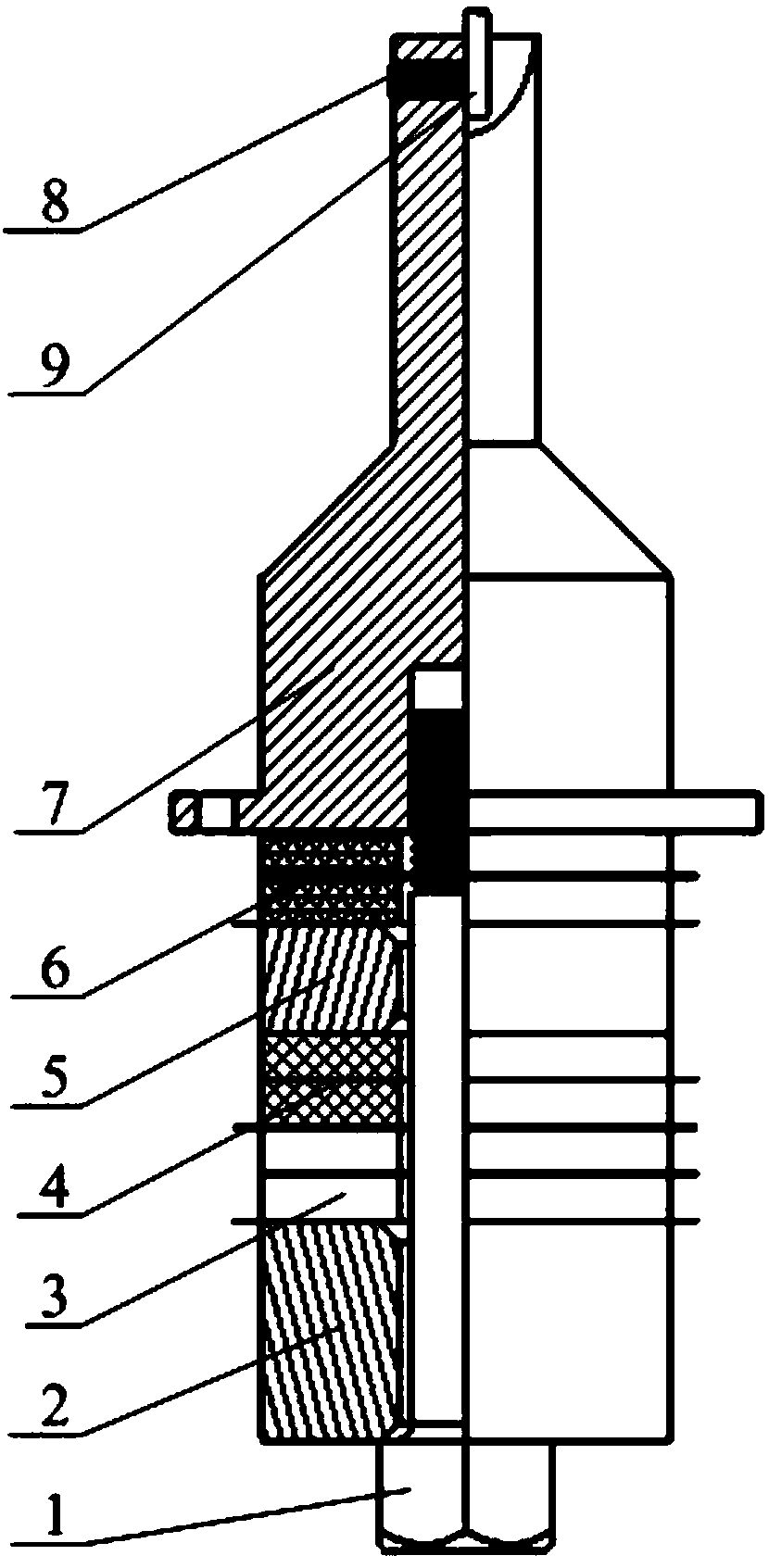

[0032] see figure 1 , Figure 1A , Figure 1B As shown, a longitudinal bending compound mode three-dimensional ultrasonic vibration assisted cutting device of the present invention, the cutting device includes a fastening bolt 1, a rear cover plate 2, a first excitation source 3, a second excitation source 4, a middle cover Plate 5, the third excitation source 6 and the flanged front cover 7; the structures of the rear cover 2 and the middle cover 5 are both hollow cylinder structures; 7 in the sipe 76. After the threaded section of the fastening bolt 1 passes through the rear cover plate 2, the first excitation source 3, the second excitation source 4, the middle cover plate 5 and the third excitation source 6, it is threaded on the flanged front cover plate 7. B threaded hole 73, so that the rear cover 2, the first excitation source 3, the second excitation source 4, the middle cover 5, the third excitation source 6 and the front cover 7 are fastened together; the tool ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com