Foamless cleaning agent as well as preparation method and application of foamless cleaning agent

A cleaning agent, potassium acetate technology, applied in the field of oil drilling, can solve the problems of unsustainable gas production operation, achieve good dispersion and solubilization ability, prevent clogging, and ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

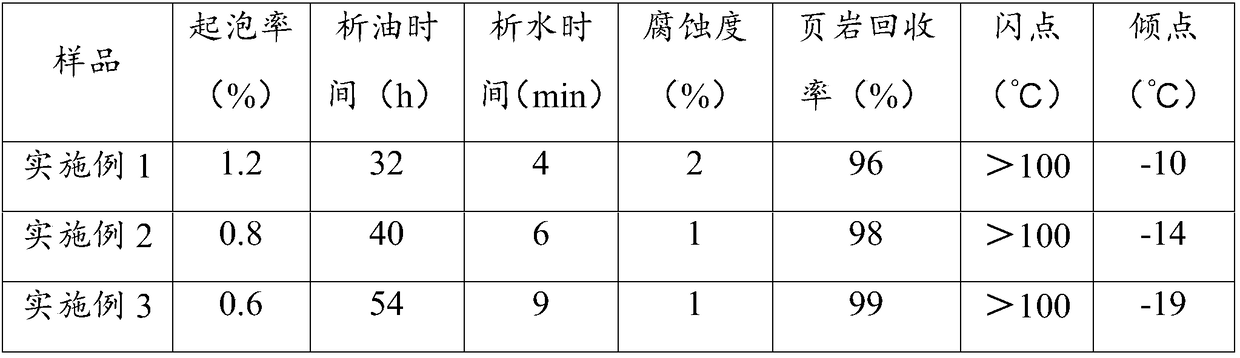

Embodiment 1

[0037] A kind of non-foaming cleaning agent of the present embodiment, described cleaning agent comprises coconut acid diethanolamide 5kg, n-decyl glucoside 5kg, polydimethylsiloxane 0.3kg, oleic acid group hydroxyethylimidazoline 1kg, isothiazolinone 0.05kg, potassium acetate 7kg, xanthan gum 0.3kg, paraffin oil 30kg and water 30kg.

[0038] The preparation method of the non-foaming cleaning agent of the present embodiment, comprises the steps:

[0039] (1) take by weighing according to the weight of each component for subsequent use;

[0040] (2) The water taken by weighing is put into the stirred tank, then the potassium acetate that is weighed is added, stirred evenly, fully dissolving, obtains potassium acetate aqueous solution for subsequent use;

[0041] (3) under the condition of stirring, the xanthan gum weighed is added in the potassium acetate aqueous solution, and the stirring tank is heated, and the heating temperature is to 40° C.;

[0042] (4) The solution hea...

Embodiment 2

[0046] A kind of non-foaming cleaning agent of the present embodiment, described cleaning agent comprises cocoic acid diethanolamide 7.5kg, n-decyl glucoside 10kg, polydimethylsiloxane 0.6kg, oleic acid group hydroxyethyl Imidazoline 2kg, isothiazolinone 0.22kg, potassium acetate 9kg, xanthan gum 0.35kg, paraffin oil 42kg and water 35kg.

[0047] The preparation method of the non-foaming cleaning agent of the present embodiment, comprises the steps:

[0048] (1) take by weighing according to the weight of each component for subsequent use;

[0049] (2) The water taken by weighing is put into the stirred tank, then the potassium acetate that is weighed is added, stirred evenly, fully dissolving, obtains potassium acetate aqueous solution for subsequent use;

[0050] (3) under the condition of stirring, the xanthan gum weighed is added in the potassium acetate aqueous solution, and the stirring tank is heated, and the heating temperature is to 45° C.;

[0051] (4) the solution...

Embodiment 3

[0055] A kind of non-foaming cleaning agent of the present embodiment, described cleaning agent comprises cocoic acid diethanolamide 10kg, n-decyl glucoside 15kg, polydimethylsiloxane 1kg, oleic acid group hydroxyethylimidazoline 3kg, isothiazolinone 0.4kg, potassium acetate 11kg, xanthan gum 0.4kg, paraffin oil 55kg and water 40kg.

[0056] The preparation method of the non-foaming cleaning agent of the present embodiment, comprises the steps:

[0057] (1) take by weighing according to the weight of each component for subsequent use;

[0058] (2) The water taken by weighing is put into the stirred tank, then the potassium acetate that is weighed is added, stirred evenly, fully dissolving, obtains potassium acetate aqueous solution for subsequent use;

[0059] (3) under the condition of stirring, the xanthan gum weighed is added in the potassium acetate aqueous solution, and the stirring tank is heated, and the heating temperature is to 50° C.;

[0060] (4) The solution heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com