One-bath fabric dyeing process of pretreatment and dyeing

A fabric dyeing and process technology, applied in the field of textile printing and dyeing, can solve the problems of easy fading, small dyeing batches, long production process, etc., and achieve the effects of shortening the process, improving color fastness, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

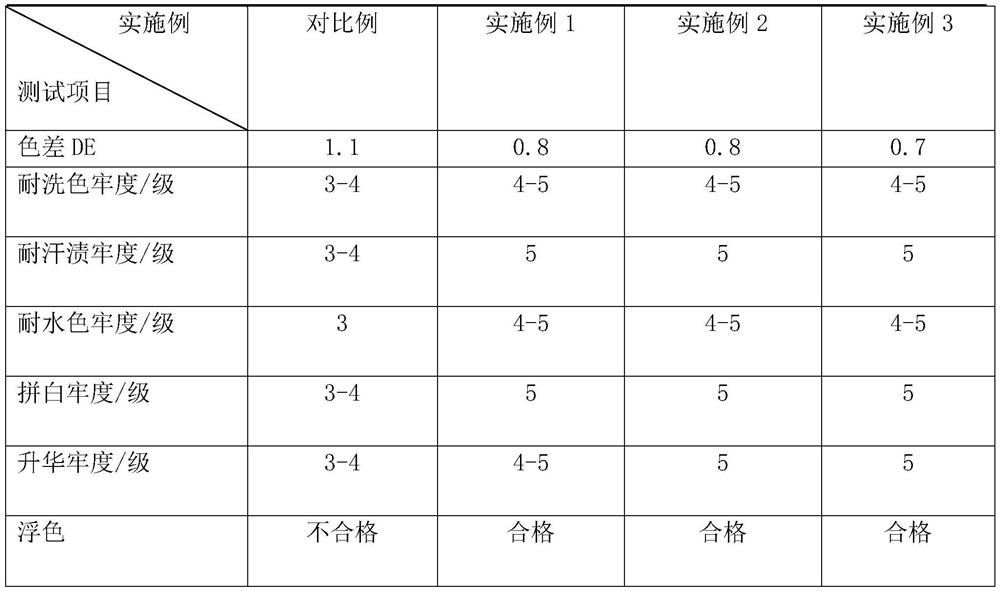

Examples

preparation example Construction

[0020] The preparation method of the high-temperature leveling agent is as follows: add sodium dodecylbenzenesulfonate, dicarboxypolyether, p-toluenesulfonic acid, and isobutyltriethoxysilane to the reaction kettle in proportion, raise the temperature to 150°C, and keep warm React for 160 minutes, then continue to heat up to 250°C, keep warm for 60 minutes, then react at 300°C and 0.12MPa for 30 minutes, cool down to 120°C, add glyceryl monostearate, dimethyl terephthalate, ethylene Mix bis-stearamide, glyceryl ether oleate and water evenly, keep warm for 120 minutes, and discharge after cooling down to room temperature to obtain a high-temperature leveling agent;

[0021] Dyes include 0.6% vermilion NR dye, 1.1% H4GFS scarlet dye and 0.28% S-5BL carnelian dye;

[0022] The alkaline reduction cleaning agent is the alkaline reduction cleaning agent DR-84CN produced by Wuxi Derong Chemical Co., Ltd.;

[0023] The penetrant is the penetrant JFC produced by Jiangsu Haian Petroche...

Embodiment 1

[0026] A kind of fabric dyeing process of pretreatment and dyeing one bath, comprises the following steps:

[0027] (1) One bath of pretreatment and dyeing: enter the cloth, add water, add 0.5g / L glacial acetic acid, 0.8g / L dispersant, 0.5g / L penetrant, heat up to 85°C at 3.5°C / min , add 1.5g / L high-temperature leveling agent, keep warm for 15min, add dye, then raise the temperature to 105℃ at 1℃ / min, add 2g / L caustic soda, 2g / L hydrogen peroxide, keep warm for 15min, and then heat up at 2.5 ℃ / min to raise the temperature to 140°C, keep it warm for 35 minutes, and finally cool down to 75°C at 3.5°C / min, and drain the liquid. Specifically, the bath ratio of pretreatment and dyeing is 1:5.5;

[0028] (2) Post-treatment: Add water, add 0.6g / L alkaline reducing cleaning agent, 0.8g / L glacial acetic acid, heat up to 75°C at 2.5°C / min, wash for 25min, drain, add water again, and add 0.8g / L liquid wax, treatment for 10min;

[0029] Specifically, the high-temperature leveling agent ...

Embodiment 2

[0036] A kind of fabric dyeing process of pretreatment and dyeing one bath, comprises the following steps:

[0037] (1) One bath of pretreatment and dyeing: enter the cloth, add water, add 1.5g / L glacial acetic acid, 0.5g / L dispersant, 0.8g / L penetrant, heat up to 75°C at 2.5°C / min , add 0.5g / L high-temperature leveling agent, keep warm for 25min, add dye, then raise the temperature to 115℃ at 2℃ / min, add 1g / L caustic soda, 3g / L hydrogen peroxide, keep warm for 5min, and then heat up at 1.5 ℃ / min to raise the temperature to 130°C, keep it warm for 45 minutes, and finally cool down to 65°C at 2.5°C / min, and drain the liquid. Specifically, the bath ratio of pretreatment and dyeing is 1:4.5;

[0038] (2) Post-treatment: Add water, add 0.2g / L alkaline reducing cleaning agent, 1.2g / L glacial acetic acid, heat up to 85°C at 3.5°C / min, wash for 15min, drain, add water again, and add 0.3g / L liquid wax, treatment for 20min;

[0039]Specifically, the high-temperature leveling agent in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com