Dual-opening magnetic circuit iron core device body clamping device used for electrical equipment

A technology for power equipment and clamping devices, applied in circuits, transformer/inductor magnetic cores, electrical components, etc., can solve the problems of application of clamping devices without iron cores, and achieve the effect of strong adaptability and satisfying clamping requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

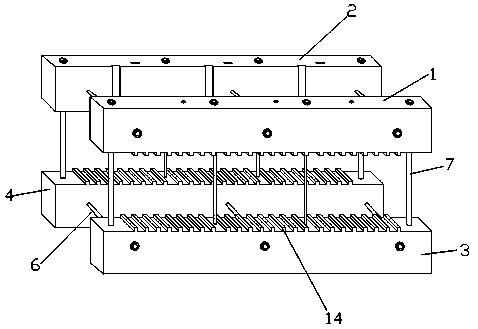

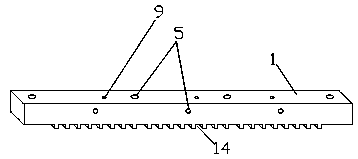

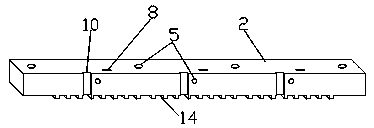

[0029] Figure 4 and Figure 5 Shown is a schematic diagram of the assembly structure between the five-column combined iron core and the clamping device. The high-voltage upper clamp 1, the low-voltage upper clamp 2, the high-voltage lower clamp 3 and the low-pressure lower clamp 4 are clamped on the core body. On the coil, the vertical pull screw 7 connecting the high-voltage upper clamp 1 and the high-voltage lower clamp 3 and the low-voltage upper clamp 2 and the low-voltage lower clamp 4 is located in the interval formed between the coils, connecting the high-voltage upper clamp 1 The horizontal pull screw 6 between the low pressure upper clamp 2 and the high pressure lower clamp 3 and the low pressure lower clamp 4 is located in the "V" shaped opening formed on the five-column combined iron core 11. The screw rod 6 and the vertical pulling screw rod 7 can tightly clamp the five-column combined iron core with the high-voltage upper clamp 1 , the low-pressure upper clamp 2...

Embodiment 2

[0031] Figure 6 and Figure 7Shown is a schematic diagram of the assembly structure between the three-column combined iron core and the clamping device. The high-voltage upper clamp 1, the low-voltage upper clamp 2, the high-voltage lower clamp 3 and the low-pressure lower clamp 4 are clamped on the core body. On the coil, the vertical pull screw 7 connecting the high-voltage upper clamp 1 and the high-voltage lower clamp 3 and the low-voltage upper clamp 2 and the low-voltage lower clamp 4 is located in the interval formed between the coils, connecting the high-voltage upper clamp 1 The horizontal pull screw 6 between the low pressure upper clamp 2 and the high pressure lower clamp 3 and the low pressure lower clamp 4 is passed through the triangular hole formed on the three-column combined iron core 12. The screw rod 6 and the vertical pulling screw rod 7 can tightly clamp the five-column combined iron core with the high-voltage upper clamp 1 , the low-pressure upper clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com